|

|||

|

|

|||

|

Page Title:

TOPIC 3. FUEL PUMP AND FUEL FILTER |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 3. FUEL PUMP AND FUEL FILTER

A. DESCRIPTION

e. Make certain all pump cover screws are

tight.

The fuel pump is a mechanical diaphragm type with an

attached strainer and sediment bowl. The pump is

mounted on the side of the engine and is operated by an

eccentric on the engine camshaft.

Fuel from the tank enters the strainer sediment bowl on

the suction stroke of the pump and is forced to the

carburetor on the pressure stroke. Action is controlled

by two valves in the cover assembly.

On ACP model trucks the fuel strainer is connected

directly to the tank and fuel is delivered to the fuel pump

through a connecting hose (Fig. 1-3).

B. SERVICE AND INSPECTION

Quite often engine malfunctioning can be traced to a

clogged fuel pump; therefore, periodically clean

sediment bowl and strainer screen.

Loosen capnut, swing clamp wire to one side, and

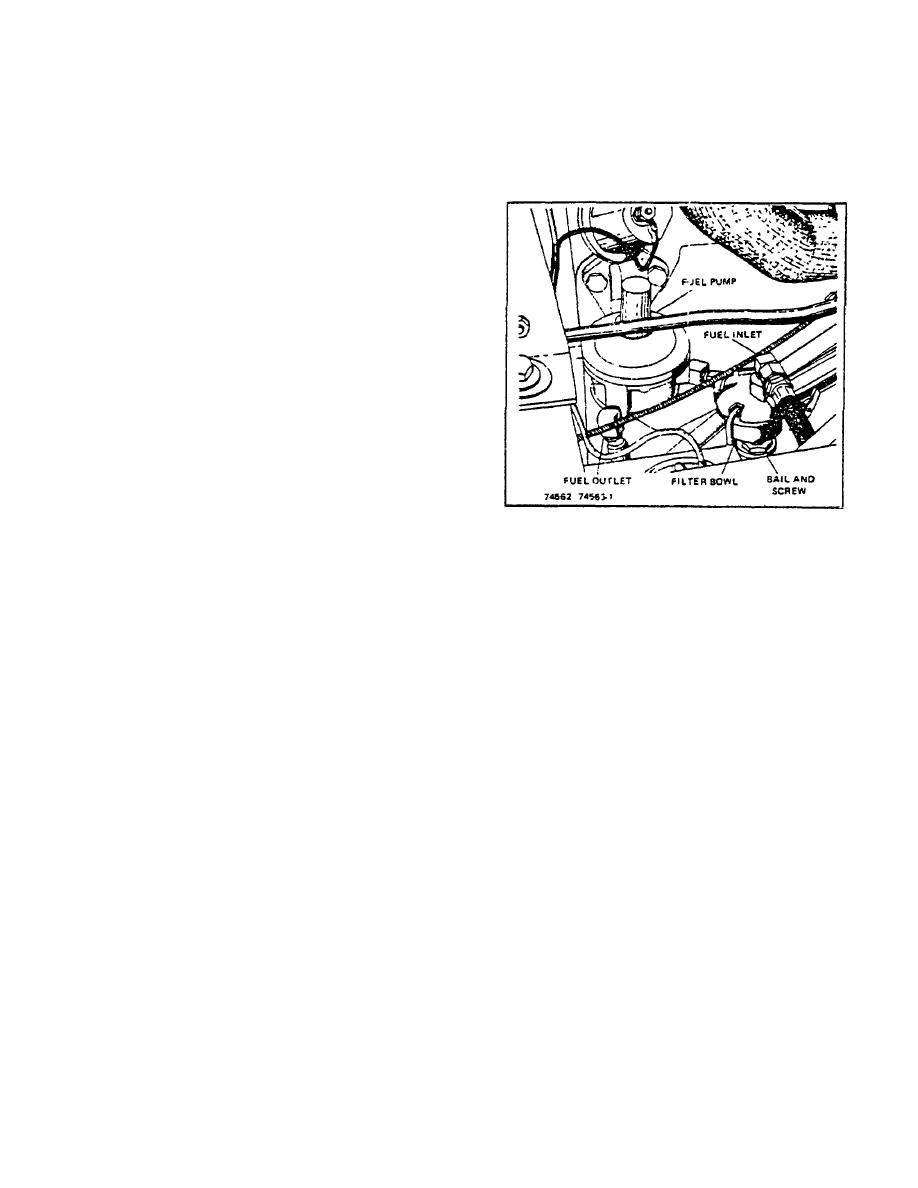

Figure 3-1. Fuel Pump and Filter Mounting (ACC Model

remove bowl. Thoroughly clean bowl and screen. If

Trucks)

there is excessive dirt on the screen or in the bowl,

check fuel tank and source of supply.

f. Test pump for proper operating pressure by

disconnecting outlet line and attaching test

If pump is supplying insufficient fuel, engine will stall or

gauge to fuel cutlet port. Run engine at 1800

falter. Check the following:

r.p.m. on fuel remaining in carburetor and note

pressure on gauge.

Pressure should be

1. Make sure there is fuel in the tank and the shut-

between 1-1/2 P.S.I. minimum and 2-1/4 P.S.I.

off valve at sediment bowl is fully open.

maximum. Pressure below minimum indicates

excessive wear. It may also indicate a ruptured

2. Disconnect fuel outlet line from pump. Remove

diaphragm, worn, dirty or gummy valves and

high tension wire from ignition coil and turn the

seats. Any of the above require removal of the

engine over several revolutions. If fuel spurts

pump for replacement.

from pump outlet, it indicates pump, gas lines

and fuel tank are not at fault.

If pump is supplying too much fuel, it will drip from the

carburetor, or the engine will not idle smoothly, and will

3. If little or no fuel flows, perform the following:

be hard to start. Check the following:

a. Check for leaking gasket at sediment bowl

1. Perform Step f above for testing the pump for

or top cover of the pump.

proper operating pressure.

b. Remove and

clean

fuel

screen

in

2. A pressure above maximum indicates too tight a

sediment bowl.

diaphragm or too strong a diaphragm spring.

Poor riveting on a diaphragm assembly may

c. Inspect copper fuel line for restrictions.

also result in too high a pressure due to fuel

Blow out with compressed air or replace 'f

seeping between diaphragm layers, bulging the

damaged.

diaphragm and causing it to act as if It were

stretched too tightly.

The above requires

d. Inspect flexible fuel line for breaks or a

removal of the fuel pump for replacement.

porous condition. Replace if necessary.

R-123-1

3-57

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |