|

|||

|

|

|||

|

Page Title:

TOPIC 14. FILLER BLOCKS AND OIL GUARD |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 14. FILLER BLOCKS AND OIL GUARD

A. DESCRIPTION

The rear and front main bearings are sealed to the

cylinder block and the oil pan by a rear oil guard, rear

filler block, and a front filler block; these three

components are semicircular die castings equipped with

jute seals and neoprene seals (Figure 6-1). The oil

guard fits in the cylinder block, Just to the rear of the

rear main bearing. The rear filler block is assembled to

the cylinder block with capscrews, directly under the oil

guard.

Jute seals are mounted on the inner semicircular

grooves of the rear oil guard and filler block, where

contact is made with the crankshaft.

The outer

semicircular groove of the rear filler block also has

mounted a neoprene seal where contact is made

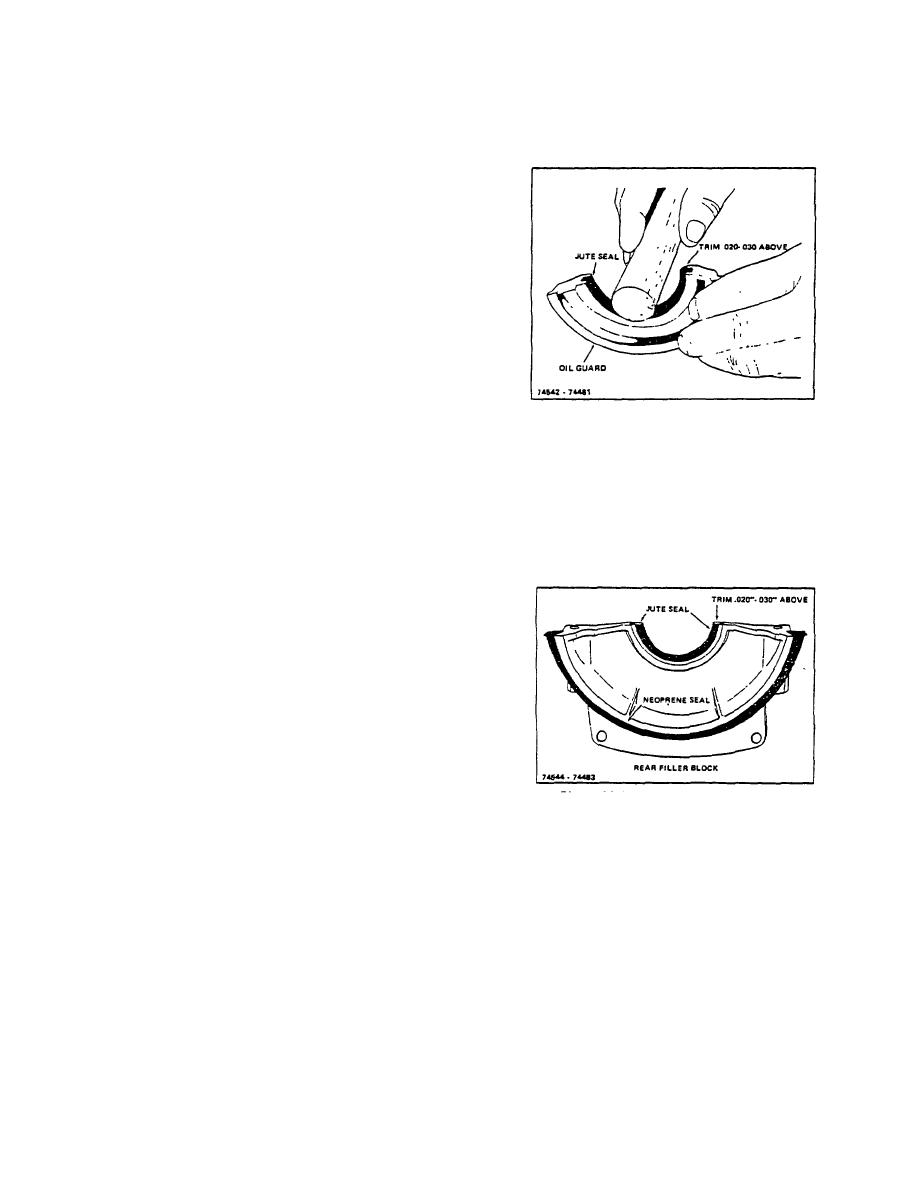

Figure 14-1. Installing Jute Seal in Oil Guard

between the filler block and the oil pan.

4. Press packing seal into the grooves of both the

The front filler block is assembled to the front of the

filler block and the oil guard. Then, using a

cylinder block with capscrews. A neoprene seal is

piston pin, a smooth hammer handle, or some

mounted on the outer semicircular groove of the front

other instrument with a rounded surface, iron

filler block to seal the connection with the oil pan.

this packing into the groove so that it is seated

firmly and expanded so that is seizes the sides.

B. REMOVAL

1. Refer

to

TOPIC

6.

CRANKSHAFT

COMPONENTS for access to Filler Blocks and

oil Guard.

2. With the engine resting on its side, remove the

rear and front filler blocks.

3. Remove the crankshaft.

4. Remove the oil guard.

C. SERVICING

Figure 14-2. Installing Jute Seal in Rear Filler Block

1. Remove the jute seals and neoprene seals from

the oil guard and the filler blocks; thoroughly

NOTE

clean inner and outer seal grooves to remove all

After installation, the jute packing will

dried cement and grease.

protrude from the grooves at either

end in varying amounts.

With a

2. Install jute seals on the oil guard and the rear

sharp knife, or razor blade, cut this

filler block. Refer to Figures 14-1 and 14-2.

off to project .020"-.030" above,

making the cut parallel to the surface

3. Jute packing for crankshaft seal as it is received

of the casting. Then slip it into place,

is approximately one-third larger in diameter

either around the crankshaft, if the

than the width of the groove. To fit the grooves

engine is still assembled, or directly

in the filler block, the packing must be crushed in

into the groove if the crankshaft is

a vise or flattened with a hammer on a flat

out.

surface so the Jute packing is narrow' enough to

fit into the grooves.

3-46

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |