|

|||

|

|

|||

|

Page Title:

TOPIC 8. PISTON AND CONNECTING RODS |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 8. PISTON AND CONNECTING RODS

A. DESCRIPTION

replace bearing shells with new ones. Inspect pistons

The pistons used are aluminum and use four rings two

for score marks or for worn, stuck or broken rings.

compression rings, one scraper ring and one three-piece

Inspect for excessive carbon deposits on piston walls

oil control ring.

and in ring grooves. Check ring grooves for excessive

wear and worn edges. Check pistons for cracks.

The rifle drilled forged connecting rods are precision

ground at the large end to receive precision type thin-

When fitting replacement pistons and rings, four different

wall bearing shells (Figure 8-1).No shims are used, since

precision checks should always be made: check ring

oversize bearing shells are available to provide a tight fit.

gap, check ring to land clearances, check pin clearance

in piston boss, and check piston skirt clearance.

A bronze bushing is burnished and diamond bored in

place in the upper end of the connecting rod.

C. INSPECTION

Pistons are available in .010", .020", .030" and .040"

1. Checking Piston Ring Gap

oversizes to provide correct tolerances when cylinders

Check the piston rings in the cylinders for gap.

are bored and honed due to wear. Piston rings are

To do this, insert a piston in the cylinder bore in

available in the same oversizes to match specific

an inverted position and then insert each ring,

pistons.

one at a time, about 2" down in the bore and

bring the bottom edge of the piston up against

the ring to square it up in the cylinder bore

(Figure 8-2).

Check the gap between the ends of the ring with

a feeler gauge in accordance with specifications

shown in TOPIC 1. FITS AND TOLERANCES.

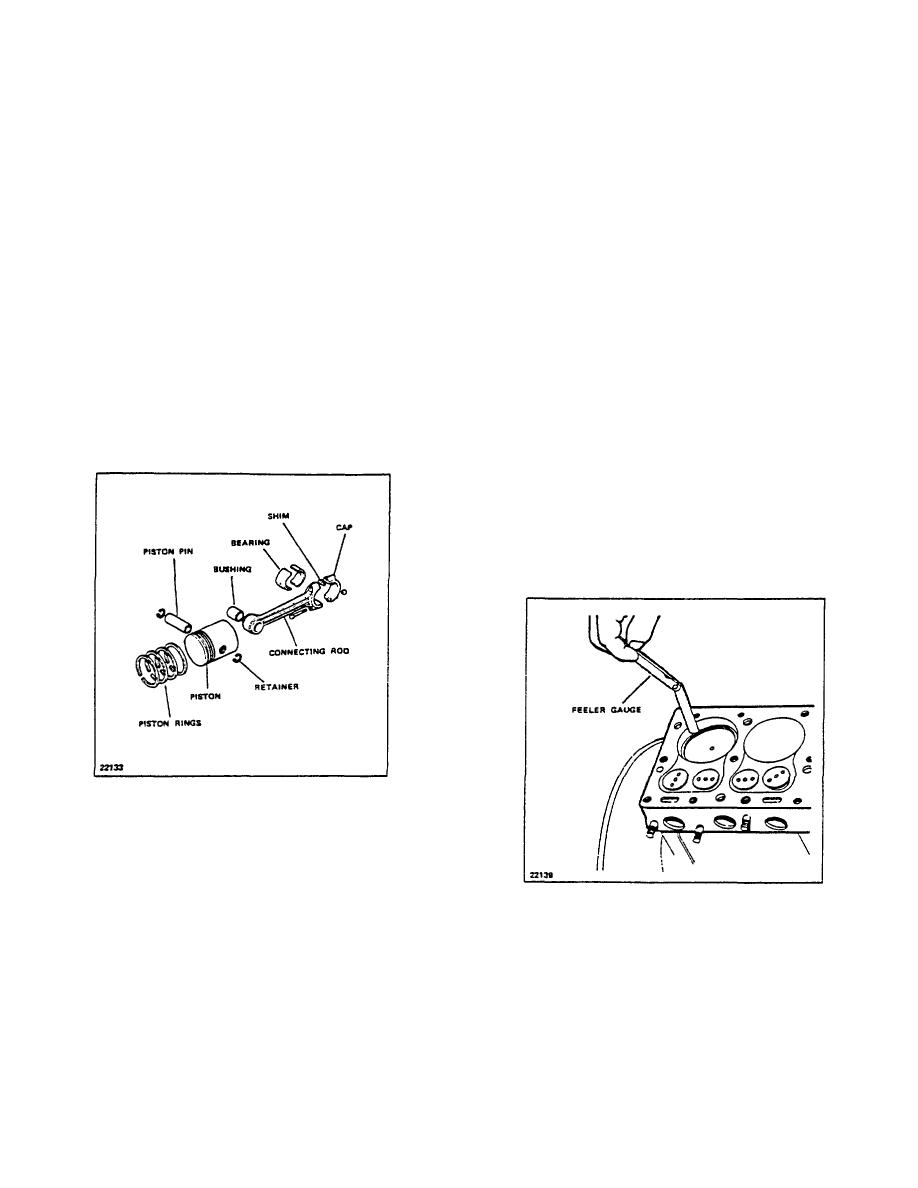

Figure 8-1. Piston and Connecting Rod Assembly

B. REMOVAL

Piston and connecting rod replacement is accomplished

with the engine out of the truck. (Refer to TOPIC 6.

CRANKSHAFT AND CRANKSHAFT COMPONENTS).

Figure 8-2. Checking Ring Gap (Typical)

All piston and rod assemblies are removed from the top

Those rings with gaps less than specified should be

of the bore. Before removing, however, it is important

carefully dressed off with a flat cut file until the correct

that the ridge at the top edge of the bore be removed by

clearance is obtained. Fairly wide ring gaps, near the

using a Ridge Cutting tool. If the same bearings are to

top limit, are far less detrimental to engine

be reused, be sure the bearing shells are kept in order

performance than gaps which are too tight. The two

with respect to which rod they go in, which is top and

top rings require greater end gap than the lower rings

which is bottom. However, it is usually good practice to

because they are subjected

R-104-1

3-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |