|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

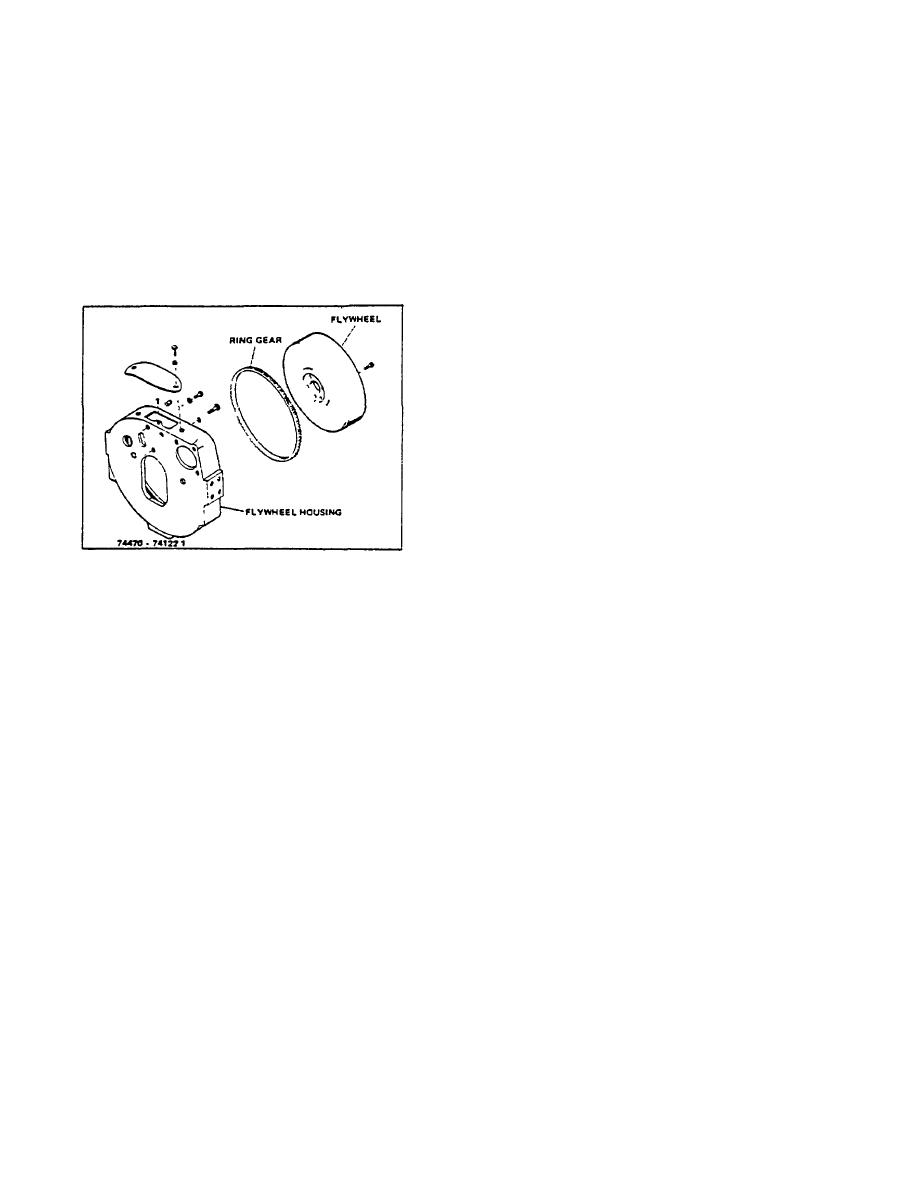

TOPIC 7. FLYWHEEL AND HOUSING

A. DESCRIPTION

B. REMOVAL

The flywheel is a kinetic energy device which is set in

1. Flywheel

motion by the starter motor to initially turn the crankshaft.

To service flywheel or flywheel housing, it is

When the engine starts, the crankshaft drives the

necessary to first remove transmission. Refer to

flywheel which then employs its kinetic energy to

REPAIR MANUAL TRANSMISSIONS. Remove

develop torque conversion and smooth rotation required

two capscrews which are opposite each other

by the transmission.

and install guide studs. Remove remaining

capscrews and slide flywheel off over guide

studs.

2. Flywheel Housing

If more than one engine is being rebuilt at a

time, the housing should be identified with its

original cylinder block and should be

reassembled so that it is mounted on the same

cylinder block in the rebuilding process. Loosen

capscrews on oil pan to relieve pressure at pan

section of oil seal in flywheel housing. Remove

two capscrews opposite each other and install

guide studs.

3. Ring Gear

If replacement of ring gear is necessary, remove

ring gear from flywheel by grinding a notch

Figure 7-1. Flywheel, Ring Gear, and Flywheel Housing

through gear at root of one of the teeth, then

expand ring and drive it from its position. Do not

The flywheel is bolted securely to a flange on the rear

attempt to remove the ring gear without first

end of the crankshaft. One of the capscrew holes is

expanding it. To expand gear, heat to 475.

offset and the flywheel can be attached to the crankshaft

flange in only one position. The ring gear. which

meshes with the starter motor gear, is mounted around

C. INSPECTION

the flywheel.

It is very important that all burrs and nicks be removed

The flywheel housing is bolted to a machined surface of

from surface of flywheel that fits against flange of

the crankcase, and in its upper outer edge it contains an

crankshaft. If surface is not smooth and true, flywheel

opening through which the timing (T.D.C.) mark on the

may wobble, which will result in improper torque

flywheel can be observed.

converter operation and engine vibration.

The flywheel is machined and balanced so that the

To be sure that the crankshaft flange has not been

clutch face and locating counterbore run true to its axis.

sprung or otherwise damaged or that the counterbore in

The flywheel and housing seldom need replacement.

the flywheel, which locates it on the crankshaft. is not

However, whenever either component part is removed

damaged, mount an indicator on the flywheel housing

both should be checked for run-out. When run-out is not

and check the flywheel for run-out (Figure 7-2).

within limits specified in TOPIC 1 FIT AND

Maximum indicated reading must not be more than

TOLERANCES, the assembly should be checked to

.008".

determine the cause and corrected.

CAUTION

When checking run-out remove spark

plugs to allow engine to be turned

over freely.

R-104-1

3-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |