|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

NOTE

Refer to following paragraph F for

LIFT CYLINDER BLEED SERVICE.

E. LIFT CHAIN ADJUSTMENT

When it becomes apparent that the fork carriage is not

level, that the lift chains are loose, or that the forks (or

attachments) are higher than .25" to .50" above the floor

when the lift cylinder is fully lowered, then the lift chains

require adjustment.

NOTE

ALL CLUSTER CYLINDERS are

adjusted

with

the

PRIMARY

Cylinders FULLY extended.

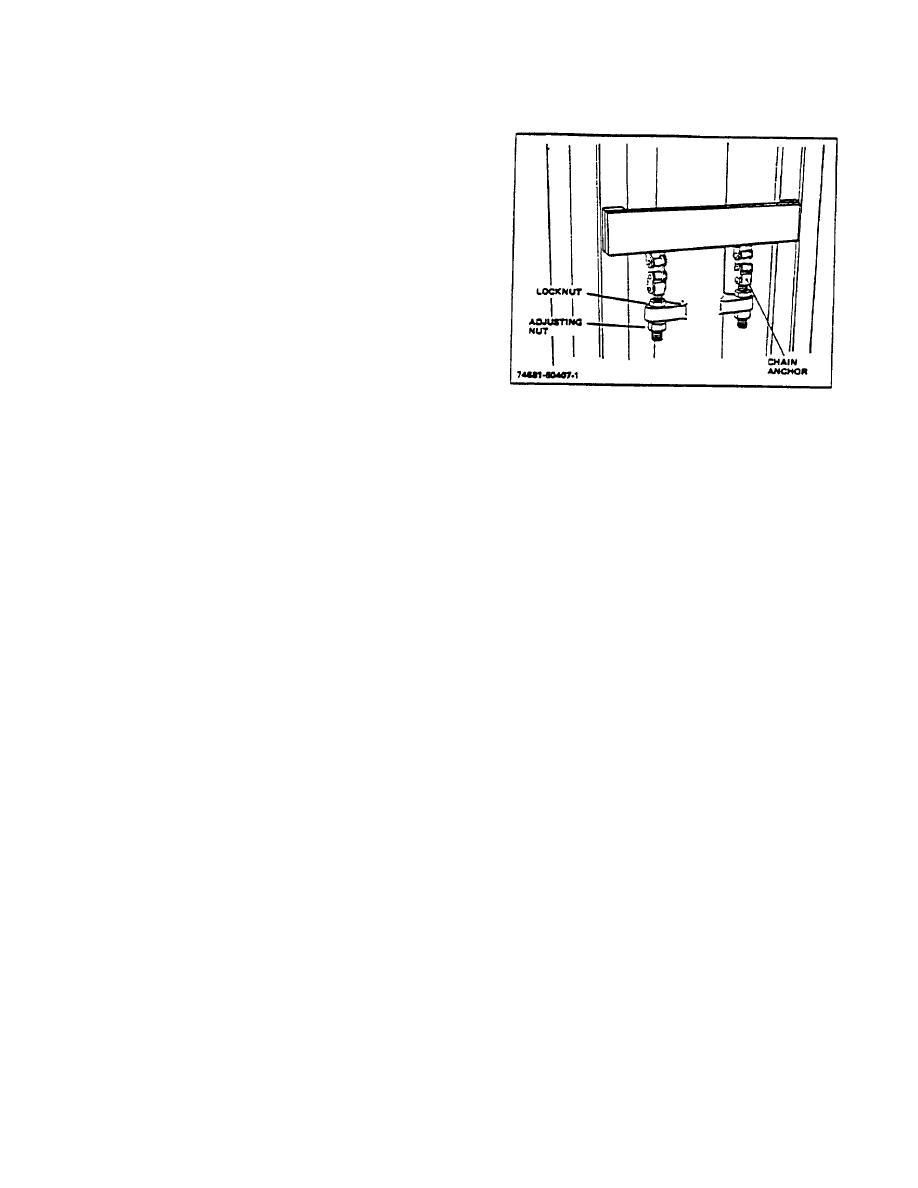

To adjust the chain length, refer to Figure 3-1 for a

Figure 3-1. Chain Adjustment (On Cylinder)

general view of chain anchor and use the following

outline:

F. LIFT CYLINDER BLEED SERVICE

1. Position the mast assembly so it is vertical.

1. Raise mast until forks are approximately 3 feet

Ensure that the inner mast section and lift

off of the ground.

cylinder are in the fully lowered position.

2. Open cylinder bleed screw(s).

2. Loosen the chain anchor locknuts (Fig 3-1).

Leave open until a stream

of

PURE

3. Chain tension is adjusted by increasing or

HYDRAULIC OIL comes out.

decreasing the chain lengths with the adjusting

nuts. Alternately tighten or loosen the chain on

NOTE

one side and then on the opposite side, until the

Be sure the oil being emitted is free

chains are snug, with no slack and carriage

of any air bubbles that may be seen

forks clear the floor within .25" to .50".

only under close inspection. Leave

bleed screws open until pure oil

4. Make certain that the lift chain tension is equal

comes out.

on each chain and that the fork carriage is level.

3. Close bleed screw(s) tight.

5. After the adjustment is completed, tighten the

locknuts securely and make certain anchors

4. Check hydraulic oil level; fill if required with pre-

were not turned.

filtered specified oil.

5. Raise and lower mast to check for leaks, if any,

and repair as necessary.

2-100

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |