|

|||

|

|

|||

|

|

|||

| ||||||||||

|

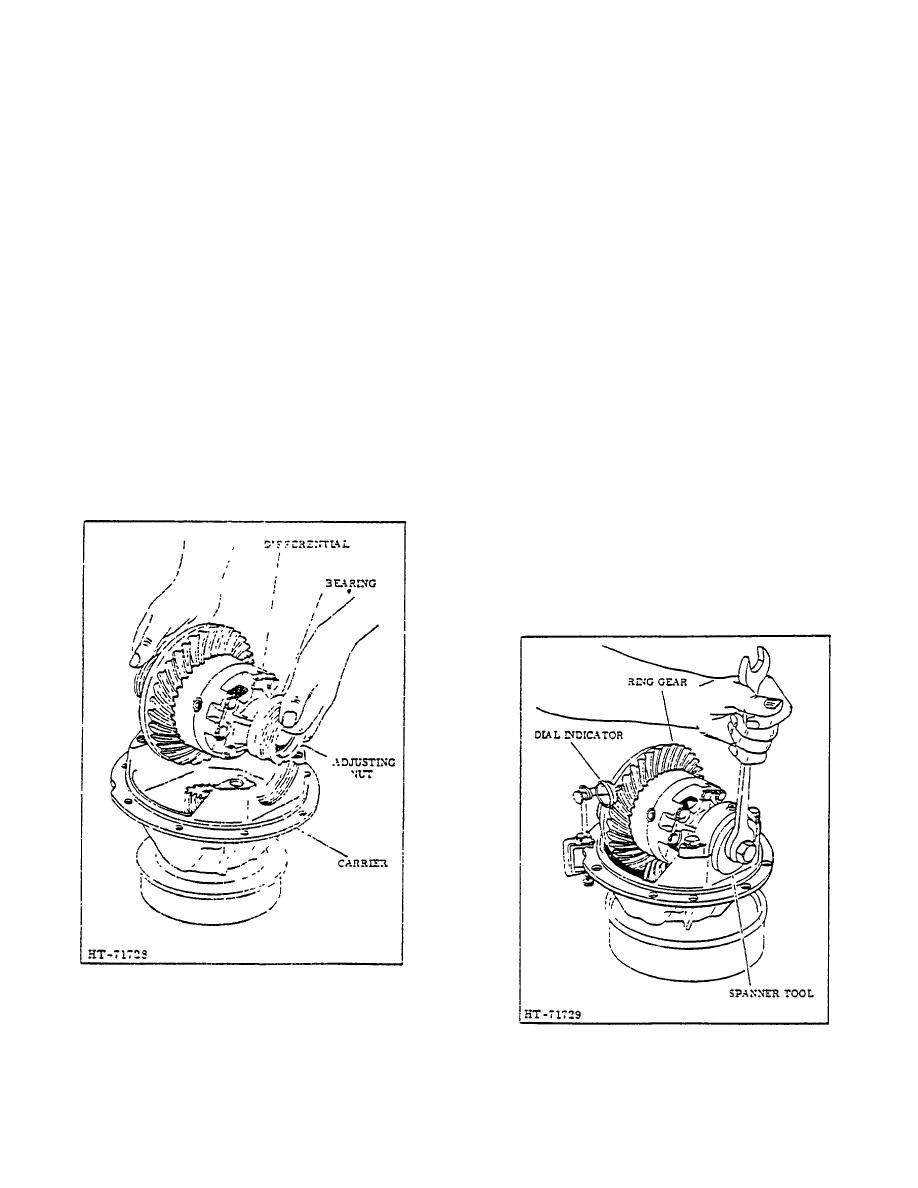

|

TM 10-3930-644-14&P

4. Remove drain plug at bottom of differential

9. Mark the bearing caps and differential housing

housing assembly and drain oil.

(Figure 14) to aid min proper alignment during

5. Remove the parking brake cable at the brake

reassembly; then remove the lockwire securing

actuating lever and disconnect the hydraulic

capscrews, cotter pins and the retaining bearing

lines or leakage return line if they might hinder

caps.

differential and carrier assembly removal.

10. Refer to Figure 15 and remove the differential

6. Remove the securing capscrews which mount

case assembly along with the adjusting nuts,

the carrier and differential assembly to the axle

bearings and bearing cups.

housing.

NOTE

WARNING

Refer

to

DIFFERENTIAL

and

Be sure to properly support the

CARRIER DISASSEMBLY Section,

carrier assembly as the capscrews

REPAIR

MANUAL

for

proper

are removed.

INSPECTION

and

REPAIR-

REPLACEMENT Procedures.

7. Carefully withdraw the carrier and differential

assembly from the axle housing and place on a

C. INSTALLATION

suitable workbench.

1. Refer to Figure 15 and install the differential

case assembly along with adjusting nuts,

NOTE

bearings and bearing cups in the same relative

It may be necessary to lightly tap the

positions as these components were prior to

carrier housing in order to free it

removal.

from seal.

2. After ensuring that the ring gear has meshed

8. Remove and discard gasket between carrier

with the pinion gear, replace the bearing caps,

housing and axle housing.

but do not tighten.

CAUTION

Make sure the bearing caps are

reinstalled as marked at time of

disassembly.

3. Coat the ring gear with Prussian Blue or white

lead to obtain the tooth pattern.

Figure 15. Removing Differential from Carrier

Figure 16. Adjusting Backlash

2-70

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |