|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

wheel six times in both directions, then

f. To replace spindle, align the spindle in the

drive housing and replace the washer and

back nut off 30 minimum to 60 maximum

so cotter pin can be installed.

locknut. Tighten the nut until the spindle

fully seats, then install the cotter pin.

TORQUE VALUES:

g. Install the dust shield and the wheel

assembly.

ACC40 PS ..........120 lb ft

h. Tighten wheel bearing nuts as follows:

ACP40 PS ..........120 lb ft

Using a torque wrench, tighten nuts in

accordance with chart below; just before

reaching maximum torque, turn each

TOPIC 2. HYDRAULIC BRAKES

The brake system consists of a mechanically activated

hydraulic master cylinder with heavy duty brake lines

transmitting hydraulic pressure to the brake wheel

cylinders located behind a dust shield in each of the

drive wheels.

For a complete description of the

hydraulic braking system and service procedures, refer

to HYDRAULIC BRAKE Section.

TOPIC 3. DIFFERENTIAL

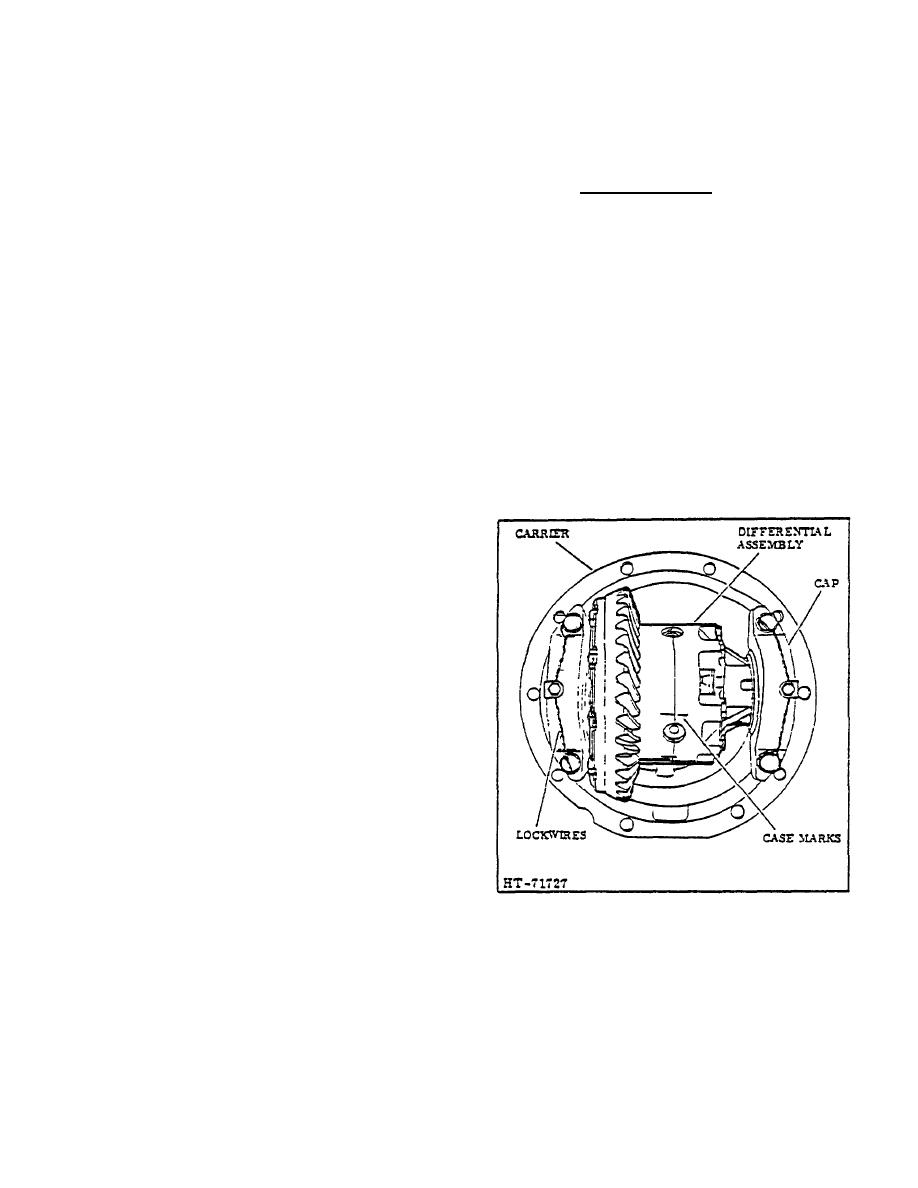

A. DESCRIPTION

The differential case and carrier consists of two parts,

the carrier assembly and the differential assembly. (See

Figure 14.) The carrier assembly is mounted at the

center of the drive unit housing (See Figure 2) and

encloses the pinion gear from the drive shaft. The bevel

ring gear is bolted to the differential case and the case in

turn houses the spider gears.

It is the purpose of the differential and carrier assembly

to accept and translate the driving torque from the drive

shaft coupling to the drive wheels of the lift truck, thus

moving the truck in a forward or reverse direction. The

following procedure is recommended to remove the

differential assembly from the carrier.

B. REMOVAL

1. Remove the drive wheels; refer to DRIVE

WHEEL REMOVAL.

2. Remove the jackshafts; refer to JACKSHAFT

REMOVAL.

3. Remove U-Joint and drive shaft coupling; refer

Figure 14. Differential and Carrier Assembly

to U-JOINTS. REMOVAL.

2-69

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |