|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

B. DRIVE UNIT SERVICE

NOTE

For service instructions on the drive

unit assembly, refer to DRIVE UNIT

should be inspected and serviced at periodic intervals.

DISASSEMBLY.

All parts should be checked for any possible damage or

excessive wear. The level of the oil in the differential

housing should be checked, and also changed when

specified.

The housing breathers should be kept clean and open to

prevent any pressure from building up in the unit.

NOTE

Refer to the LUBRICATION AND

SERVICE

GUIDE

for

specific

instructions regarding lubrication of

the drive unit.

The drive unit can

be removed as an assembly, if

desired. It will be

necessary to remove the mast

assembly min order

to remove the drive unit. The

following procedure

is recommended for drive unit

removal:

1. Removal

a. After the mast has been removed (see

LAST REMOVAL), disconnect the main

hydraulic brake line at the junction block

located on the differential housing.

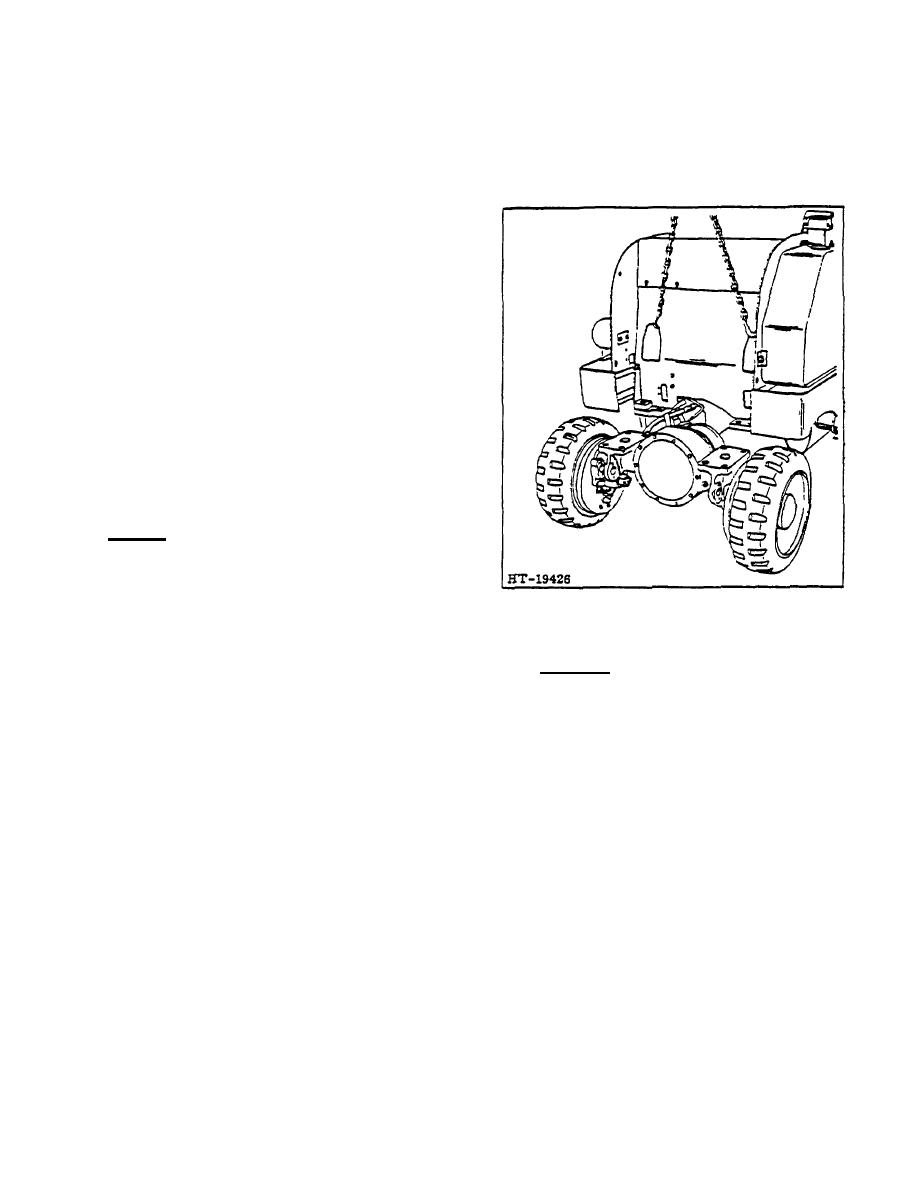

Figure 3. Drive Unit Removal

Disconnect the hydraulic lines, the

leakage return line, or any other lines

2. Installation

which are attached to the drive unit

housing.

a. To replace the drive unit assembly, carefully

b. Disconnect the emergency brake cable by

raise the truck body high enough with hoisting

removing the clevis pin from the parking

chain to position drive unit under front end at

brake actuating lever.

dowel pin location.

c. Disconnect the universal joint (see U-

b. Lower truck frame until it is securely supported

JOINTS), leaving slip joint in the

at the mounting pads and insert all mounting

transmission.

bolts and capscrews previously removed.

d. See Figure 3 and attach hoist chain hooks

c. Connect universal joint and ensure that drive

in the tilt cylinder holes in the front plate.

shaft coupling is properly aligned. (Refer to

Pull chain snug to take the weight of the

TRANSMISSION

for

proper

alignment

truck off drive axle.

procedure.)

e. Remove all mounting bolts and capscrews

d. Connect the emergency brake cable by

from mounting pads.

replacing the clevis pin at actuating level.

f. Raise the truck away from the drive unit

e. Securely tighten all mounting hardware and

and remove drive unit from under the truck

hose connections and bleed the hydraulic brake

frame. It may be necessary to apply

system. (Refer to HYDRAULIC BRAKE Section

pressure at the mounting pads in order to

for proper procedure.)

free the drive unit from the truck, because

f. Replace the mast assembly. (Refer to MAST

of the tight fit of the dowel pins in the

ASSEMBLY Section.)

mounting pads.

2-64

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |