|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

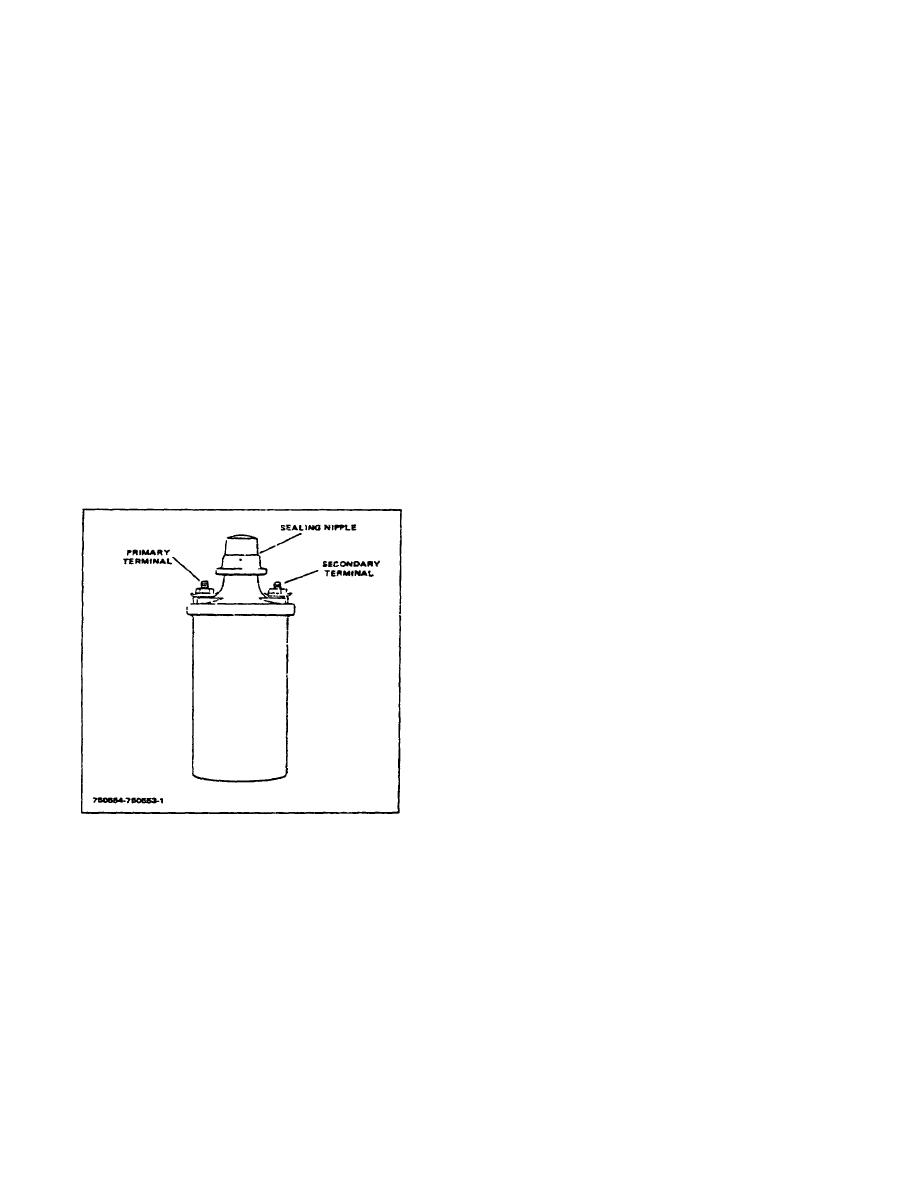

TOPIC 7. IGNITION COIL

A. DESCRIPTION

All the ignition cabling in the high tension circuit (coil to

distributor to spark plugs) is neoprene covered and is

The purpose of the high voltage ignition coil is to deliver

resistant to oil, grease, battery acid. This type of

high voltage surges to the spark plugs, via the

insulation also helps to prevent current losses.

distributor.

The ignition coil accomplishes this by

stepping up e primary input voltage of 12 V.D.C. to a

8. SERVICE

surge of about 20,000 V.D.C.

through normal

transformer action.

The ignition coil requires no particular service other than

an occasional operational performance check. Also

The coil consists of a primary and a secondary winding.

check electrical contact points for cleanliness and

(See Figure 7-I) The primary winding contains about 200

tightness of connection. The coil can only be tested on a

turns of heavy wire, and the secondary winding contains

reliable coil testing machine; however, if the engine is

about 20,000 turns of very fine wire To concentrate the

quick starting and smooth running it can be assumed

magnetic field, these windings surround a soft iron core

that the ignition coil is performing satisfactorily.

composition and are enclosed by a soft iron shell. The

entire assembly is built into a one piece steel coil case

C. REMOVAL

which is oil filled and hermetically sealed by the cap and

gaskets.

This construction prevents moisture from

I. Disconnect and label primary lead, resistor lead

entering the call and also permits faster dissipation of

and condenser lead attached to cap of ignition

the generated heat.

coil.

2. Pull high tension (secondary) wire out of center

of cap.

3. Loosen securing clamp and remove ignition coil.

4. Clean exterior of coil assembly with an

acceptable cleaning solvent. Check that primary

connectors are free of dirt and grime and

provide a good electrical connection.

5. Remove sealing nipple and check for cracks.

Replace, if damaged.

6. Inspect high tension terminal for foreign deposits

and clean,-+f necessary.

7. Inspect entire case for cracks or oil seepage.

Replace, if damaged.

8. Place ignition coil on ignition coil tester and

Figure 7-1. Ignition Coil

check for proper voltage output and voltage

breakdown. Take action as indicated by test

The coil has two primary terminals marked "+" and "-" on

results.

the exterior cap. (The proper polarity is noted on the

ignition wiring diagram.) The coil is generally mounted as

D. INSTALLATION

near as possible to the distributor in order to keep the

interconnecting high tension lead as short as possible.

1. Insert ignition coil in retaining clamp and secure

(This reduces the possibility of a high voltage arc

clamp.

between the wire and any chassis (ground) points it

might otherwise contact.)

2. Insert high tension lead in center of ignition coil

cap. Press down firmly and feel definite snap as

it seats properly. Ensure that sealing nipple is

pressed firmly against coil cap shoulder.

2-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |