|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

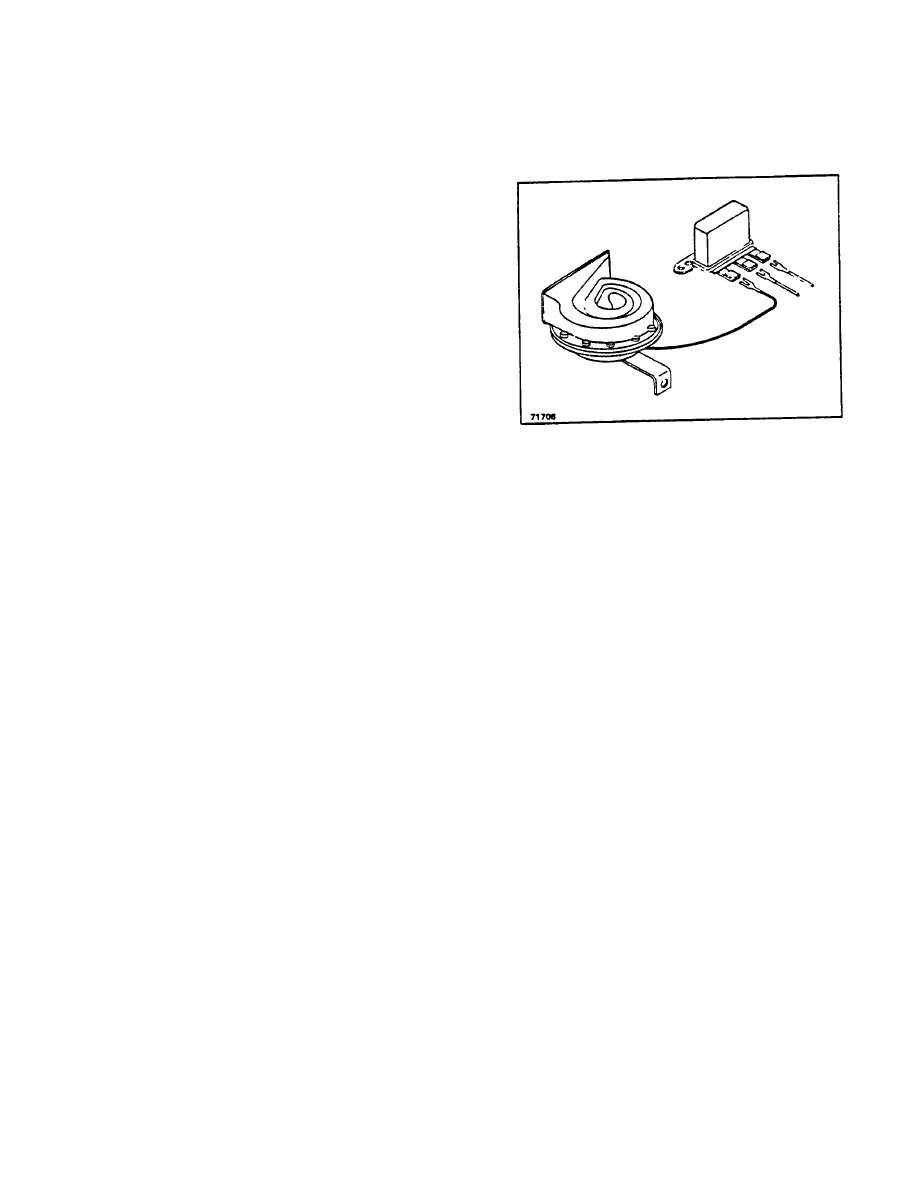

TOPIC 6. HORN AND HORN RELAY

A. DESCRIPTION

The horn is a magnetically sensitive, vibrating unit, and

is actuated by a horn relay which, in turn, is energized by

the horn button located in the center of the steering

wheel. The horn and horn relay are located on the right

hand cowl support.

The horn is relay operated to provide shorter, more

direct electrical connections between the battery and the

horn. This supplies a higher.working voltage at the horn

with a resultant improved performance and avoids the

necessity of pulling the full current load through the horn

button.

When the horn button is depressed, current flows

through the relay coil, with a resulting magnetic field

Induced in the relay coil and core, which attracts the

Figure 6-1. Horn and Horn Relay

relay armature.

The armature is pulled downward

against a spring tension and closes the battery to horn

2. If horn signal is weak and voltage at horn

circuit contact points.

terminal is normal, check volume adjusting

screw in horn cover. Screw turns in or OUT to

B. SERVICE

increase or decrease volume.

Before checking horn and horn relay, make certain

3. If horn relay requires adjustment, cover can be

battery is connected and that it is producing the rated

removed and relay points correctly gapped.

voltage output. If the battery circuit is operating properly,

(Refer to HORN RELAY ADJUSTMENT in

proceed as follows:

REPAIR MANUAL for proper procedure.) Air

gap setting at coil is 0.020" with points closed,

1. If horn produces a weak signal, connect a

and 0.018" with points opened. The correct

voltmeter from ground (truck chassis) to horn

closing voltage is 8.3 to 10.2 volts.

terminal, press horn button and note voltage

reading on voltmeter. If voltage is between 0

and 10.7 volts, check for an open circuit,

defective horn relay, poor wiring or a shorted

horn coil.

M-146-1

2-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |