|

|||

|

|

|||

|

Page Title:

TOPIC 3 ALTERNATOR AND REGULATOR |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 3 ALTERNATOR AND REGULATOR

A. DESCRIPTION

Although the alternator and its built-in regulator are

designed and constructed to give trouble-free service for

long periods of time, following a regular inspection

procedure will allow maximum life to be obtained from

the units.

The inspection frequency will be determined by the type

of operating conditions. High speed operation, high

temperatures, and heavy duty conditions all increase

wear on the alternator slip rings and bearings. The

terminals should be inspected at regular intervals for

corrosion or loose connections.

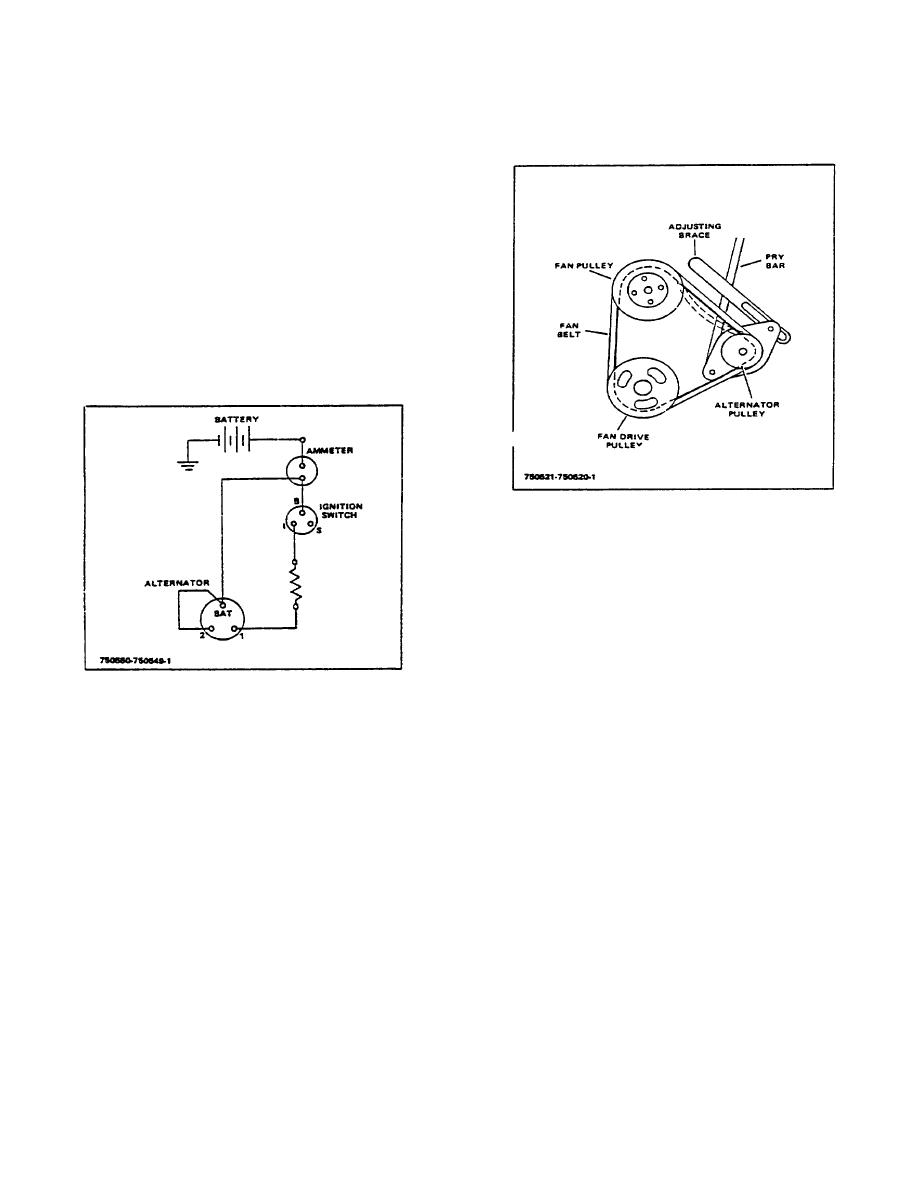

Figure 3-2. Fan Belt Tension

NOTE

For proper disassembly, inspection,

repair and reassembly procedures,

refer to REPAIR MANUAL.

C. REMOVAL

1. Disconnect the battery from the electrical circuit

prior to alternator removal/installation.

Figure 3-1. Typical Wiring Diagram

2. Disconnect the "BAT" (battery) terminal and "#1"

B. ADJUSTMENT

and "#2" post connectors at the alternator.

Be sure to check the mounting bolts for tightness and

3. Loosen adjusting brace and mounting bolt, then

the belt for alignment, corrosion, tension and wear. Belt

push alternator towards engine until fan belt is

tension should be adjusted to allow approximately 3/8"

disengaged from alternator pulley.

inward deflection of the belt between the alternator

pulley and the fan pulley with a force of about 10

4. Carefully remove the alternator from the engine

pounds. (See Figure 3-2).

as the pivot mounting bolt and adjusting brace

capscrew are removed.

When tightening belt tension, always apply pressure

against the stator laminations, never against the end

NOTE

frames.

Refer to REPAIR MANUAL for

DISASSEMBLY,

INSPECTION,

A noisy alternator can be caused by worn or dirty

REPAIR AND REASSEMBLY.

bearings, loose mounting bolts, a loose drive pulley, a

defective diode or a defective stator

M-146-1

2-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |