|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

NO.

INSPECTIONS

DAILY

Turn the steer wheels to full right and to full left

positions. Visually check positions of both axle stops;

make certain they are not missing, bent, or otherwise

3.

Battery

X

damaged.

4.

Engine Oil Level

X

5.

Fuel rank

X

2. Overhead Guard - Inspect welds and hardware

6.

Radiator Coolant Level

X

attaching overhead guard to the truck proper.

7.

Tires

X

Make sure all attaching hardware is in place and

8.

Hourmeter

X

all welds and structural members are secure.

9.

Accelerator Pedal

X

3. Battery - Check condition of battery as described

(Operational Check)

in Topic 5 BATTERY. Also, make sure that the

10.

Brakes (Operational Check)

X

battery cables are not damaged or loose and

11.

Steering (Operational Check)

X

that the connector lugs are clean and : securely

12.

Lifting and Lowering Speed

X

attached.

(Operational Check)

4. Engine Oil Level - Check level with dipstick. If

13.

Forward and Backward Tilt

X

necessary, add oil to raise level to FULL mark.

(Operational Check)

Refer to Topic 6 in this manual titled

14.

Unusual Noise (Operat ional

X

LUBRICANT SPECIFICATIONS for proper oil

Check)

recommendation.

15.

Fire Extinguisher

X

5. Fuel Tank - Fill fuel tank it end of each workday;

J. DAILY CHECK LIST EXPLANATION

this practice will prevent the condensation of

The following explanations correspond to the inspections

moisture.

in the Daily Check List. it is necessary to perform these

inspections daily. Should any discrepancy be found, it

6. Coolant Level - Maintain coolant level

should be reported to the supervisor or the responsible

approximately 1-inch below bottom of radiator

maintenance personnel.

filler tube. Add clean fresh water or antifreeze

as required.

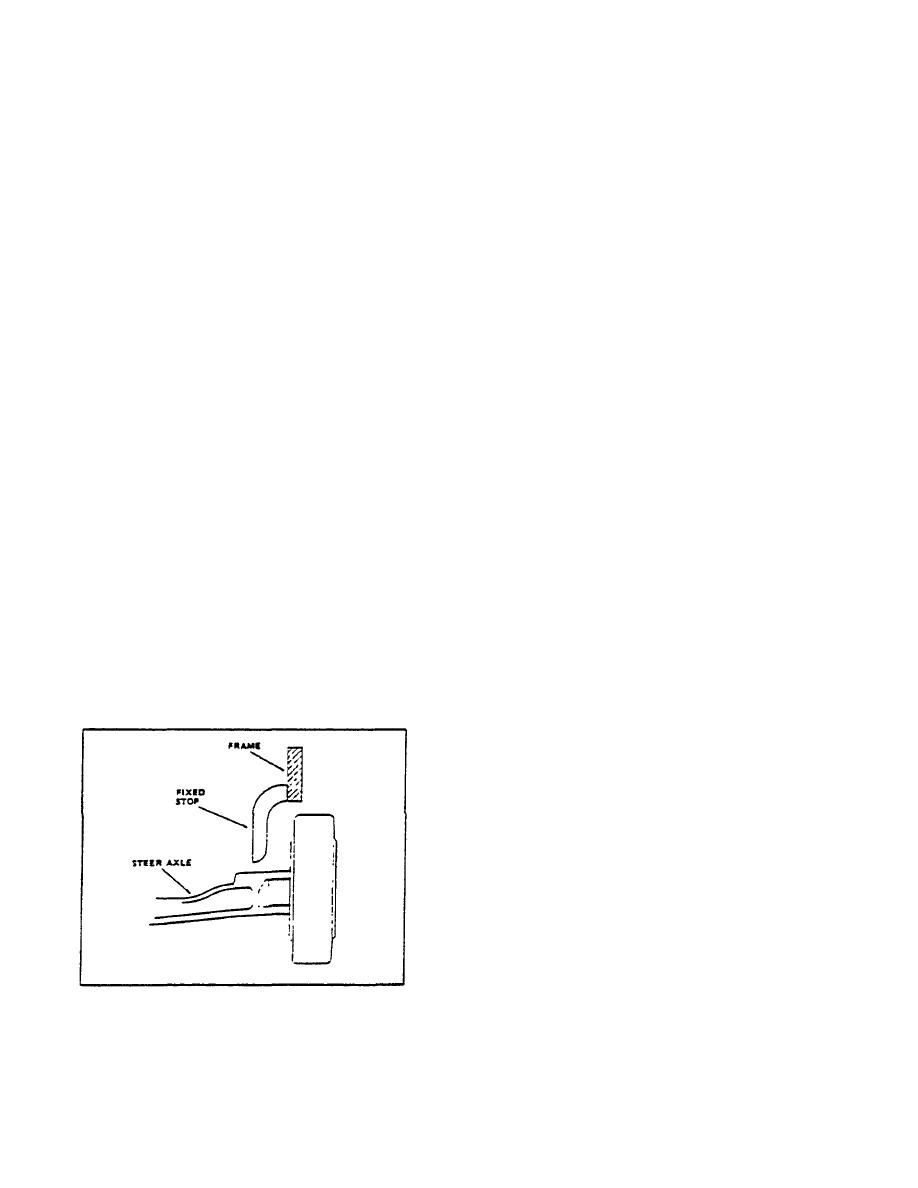

1. Steer Axle Stops Check the steer axle stops at

the beginning of each work shift. These stoops

7. Tires - Check pressure of pneumatic tires. If

are welded to the truck frame in such position

necessary, fill to pressure recommended in the

that one is directly above each of the steer axle

Maintenance Manual. Check tires for excessive

yokes (Fig 4-14).

wear and damage. Unevenly worn or badly

damaged tires will vibrate excessively and cause

hard steering. Remove steel chips and other

foreign materials from tire treads to prevent

further damage.

8. Hourmet er - Turn key switch ON and make sure

hourmeter is energized.

9. Accelerator Pedal - The truck should accelerate

smoothly from slow to fast speed.

10. Brakes - The brake pedal should have 1/2-inch

free play when it is depressed. The truck should

stop with normal brake pressure. When pedal is

fully depressed, some reserve distance should

remain. Check during operation.

11. Steering - The truck should steer smoothly and

Figure 4-14. Steer Axle Stop

freely. Check during operation.

1-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |