|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

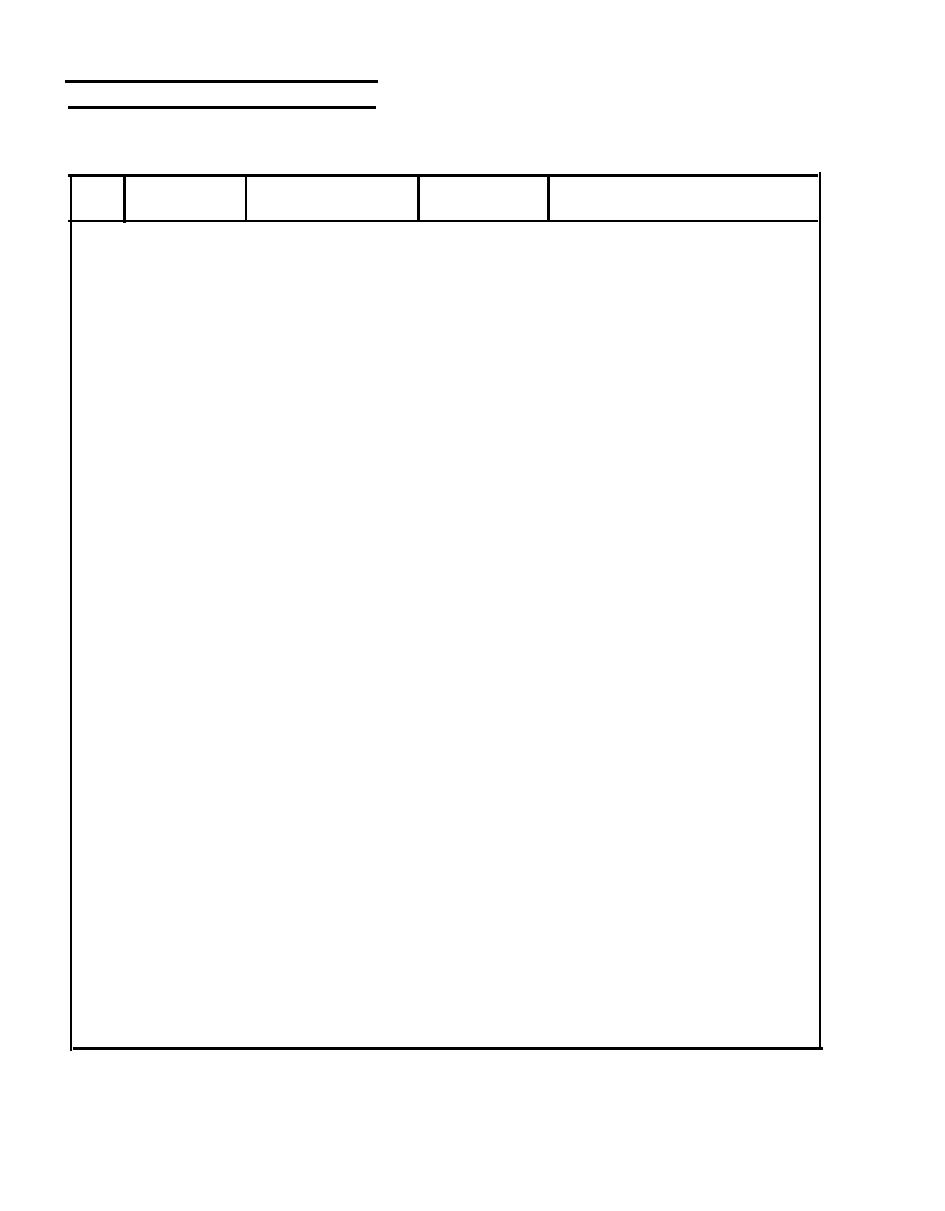

4-5. AXLE MAINTENANCE (cont)

b. Differential Case and Gear Assembly (cont).

REMARKS

ITEM

ACTION

LOCATION

STEP

INSPECTION

Inspect

8

All other parts

Inspect for wear, damage, cracks, pits

and distortion. If any of these condi-

tions are observed, replace part

NOTE

Immediately after performing inspection, coat all parts with light oil

oil to prevent corrosion.

REASSEMBLY

NOTE

Lubricate all parts and differential case (3 and 4) inner walls with

axle lubricant (refer to current lubrication order).

Position

Differential case

9

a. Ring gear (16)

flange half (4)

NOTE

If rivets were used to secure ring gear and differential case flange

half, use cap screw (12), washer (13) and nut (14) instead.

Install

b. 12 washers (13),

Tighten to 90-120 pounds foot torque

cap screws (12),

and nuts (14)

Install

c. Thrust washer (11)

[n case flange half (4)

Install

In case flange half (4)

d. Side gear (10)

Install

10

a. Four pinion gears (8)

Spider (9)

On spider

Install

b. Four thrust washers

On pinion gears

(7)

11

Differential

a. Spider (9), pinion

Install

case flange

gears (8), thrust

washers (7)

half (4)

Install

b. Side gear (6)

c. Thrust washer (5)

Install

Position

d. Differential case

Align match marks

plain half (3)

e. Eight washers (2)

Install

Install four equally spaced and draw assem-

and cap screws (1)

bly together; check for free rotation of

gears and correct if necessary. Install re-

maining cap screws (1) and washers

(2). Tighten to 90-120 pounds foot

f. Bearing cone (17)

Install

Press squarely and firmly

Install

Press squarely and firmly

12

Differential

Bearing cone (18)

case plain

half (3)

4-250

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |