|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

2-21. STARTING SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. STARTER FAILS TO CRANK (cont)

Step 2.

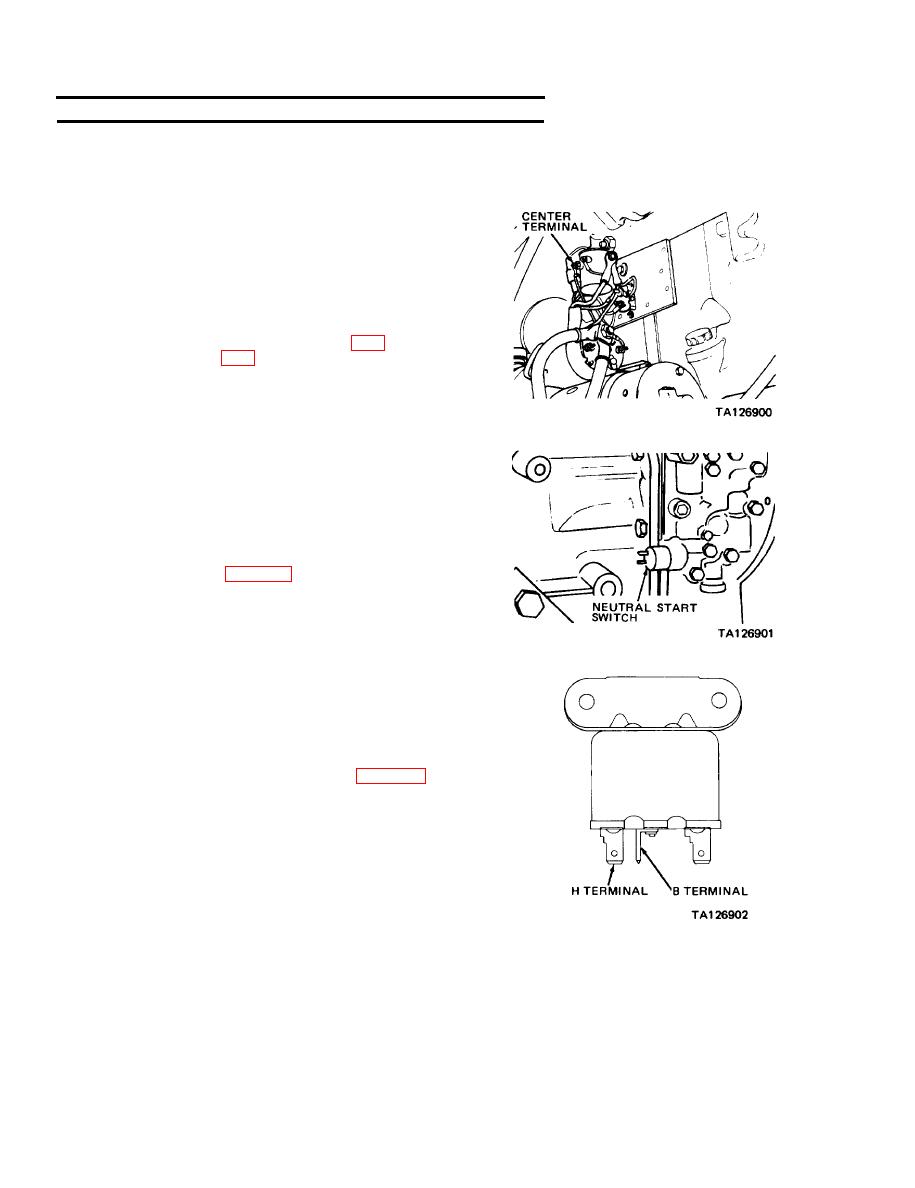

Connect voltmeter leads to center terminal of

starter relay and ground.

Note voltmeter indication while an assistant

depresses START switch.

a. If voltmeter indicates 24 Vdc,

replace starter relay (para

b . If voltmeter indicates zero

volts, proceed to step 3.

Connect voltmeter leads to terminals of

Step 3.

neutral start switch.

Note voltmeter indication while an assistant

depresses START switch.

a. If voltmeter indication is a constant

24 Vdc, replace neutral start switch

b. If voltmeter indication is a constant

zero volts, proceed to step 4.

Step 4. Tag and disconnect wires from lockout relay located

at bottom center of instrument panel.

Connect ohmmeter leads to B and H terminals

of lockout relay.

a. If ohmmeter indicates more than 0.1 ohm,

replace lockout relay (para 2-28d).

b. If ohmmeter indicates less than 0.1 ohm,

reconnect wires to lockout relay and proceed

to step 5.

Step 5. Connect voltmeter leads to IGN and GRD terminals of IGNITION switch.

With IGNITION switch set at ON, voltmeter should indicate 24 Vdc.

a. If voltmeter does not indicate 24 Vdc, proceed to step 6.

b. If voltmeter indicates 24 Vdc, proceed to step 7.

2-102

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |