|

|||

|

|

|||

|

Page Title:

FUEL SYSTEM |

|

||

| ||||||||||

|

|

TM 10-3930-638-24&P

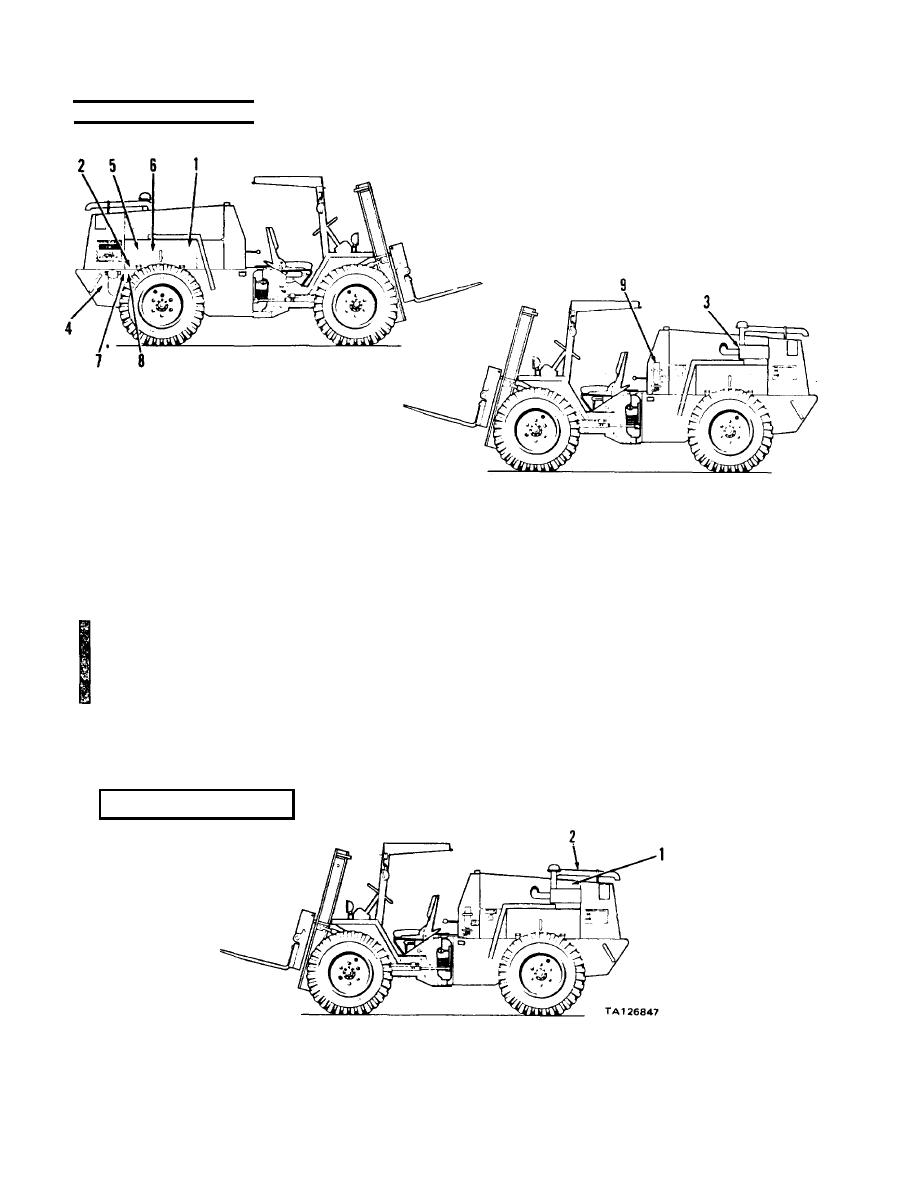

1-16. FUEL SYSTEM

1. FUEL INJECTORS, Four used; closed end, differen-

5. FUEL INJECTION PUMP. Fuel from primary and

tial pressure, hydraulically operated. hole type injector.

final fuel filters is routed to fuel injection pump where

fuel is metered accurately and applied to each cylinckr at

2. ELECTRIC FUEL PUMP. Operates bon 24 Volts;

high pressure through fuel injector nozzles at precisely

pumps fuel from fuel tank through in-line fuel filter, and

timed intervals. Fuel metering is controlled by the throt-

to fuel injection pump through primary and final fuel fi-

tle shaft lever. which is connected by cable to operator's

ters.

acclerator pedal. Speee regulating governor mounted at

WARNING

top of fuel injection pump. Equipped with electrical so-

If NBC exposure is suspected, all air filter

lenoid for positive fuel shut-off.

media should be handled by personnel wear-

ing protective equipment. Consult your unit

6. FUEL FILTERS. Primary and final fuel fuel filters

NBC Officer or NBC NCO for appropriate

remove fuel oil impurities which may damage fuel injec-

handling or disposal procedures.

tion pump and/or fuel injectors.

3. AIR CLEANER. Dry type air cleaner. Filters air be-

7. FUEL STRAINER. Located at fuel tank. Blocks pas-

fore air is applied to intake manifold.

sage of sediment to electric fuel pump.

4. FUEL TANK. 27 gallon capacity: part of rear chassis.

8. IN-LINE FUEL FILTER. Filter injection arrange-

ment for cold starting of engine. Connected by tube to

intake manifold.

engine.

combustion by-products from engine to rear of truck.

1-8 Change 5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |