|

|||

|

|

|||

|

Page Title:

Brake Applicator Valve and Differential Pressure Switch. |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

NOTE

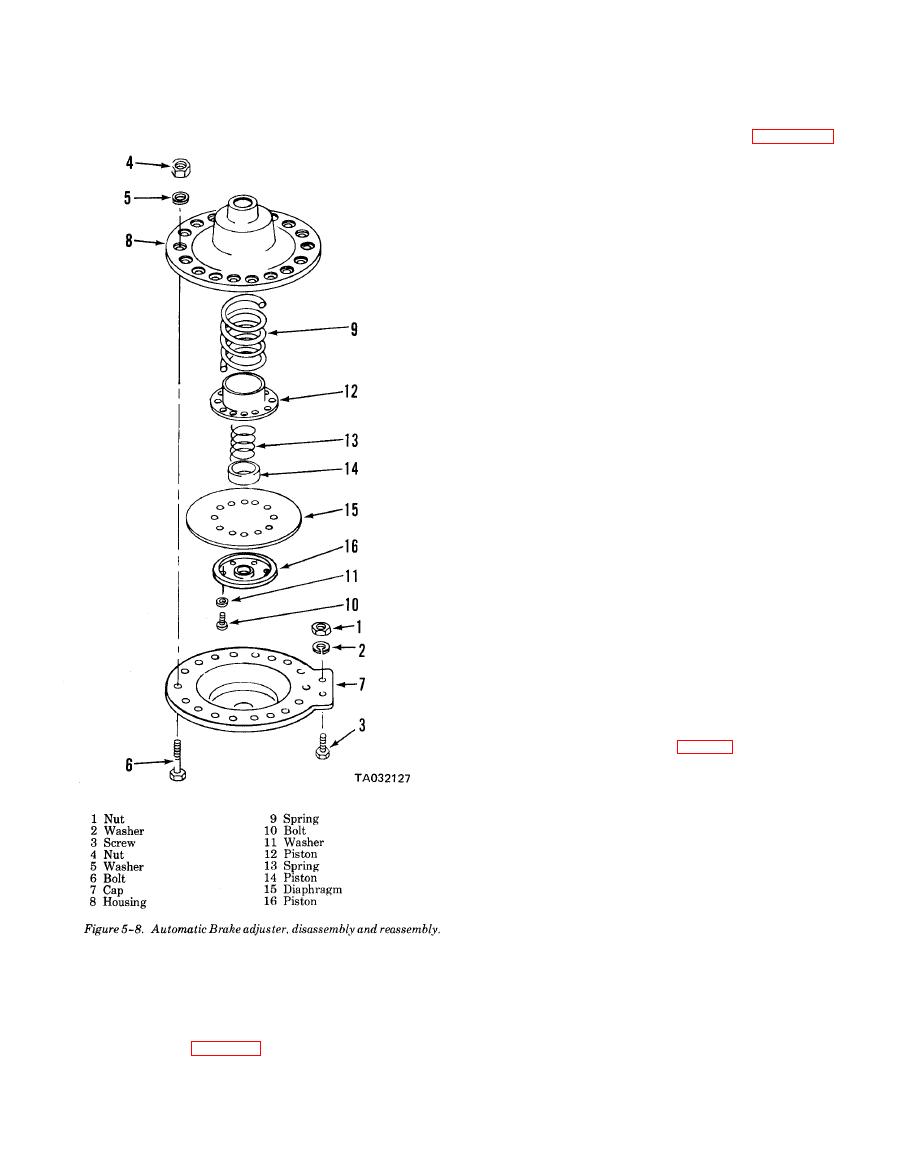

e. Installation. Install the automatic brake adjuster

Replace a defective differential pressure

and bleed the hydraulic brake system (TM

switch with a new switch.

10-3930-634-12).

and disassemble the brake valve assembly in nu-

merical sequence as follows:

NOTE

Measure the depth that the adjusting plug

(32) is below the surface of valve body (3).

Scribe a mark in line with plug slot. Record

this information, as it must be used in re-

assembly of valve.

(1) The piston (6) pulls out of the valve body(3).

(2) Shims (7 and 8) will be found inside piston.

The shims are used for adjusting the brake line pres-

sure and must be used in the reassembly of valve.

Never mix parts from another valve.

(3) Remove packing (10) from valve body,

(4) Remove retaining ring (11) and washer (12).

(5) Remove plunger (13) from valve.

(6) Remove plug (15) from valve and remove

spring (20) and guide (21).

(7) Use a wooden dowel or other soft material to

push out ball valve and seat (22).

(8) Remove plug (24) and remove pilot valve

spring (26), ball (27), spool (28) and seat (29).

(9) Remove pilot valve plug (32) and remove

spring (34), seat (35) and ball (36).

(10) Remove plug (38) and remove spring (40),

stop (41), and charging valve spool (43).

(11) Loosen locknut (45). Remove screw (46) and

remove spring (48), poppet (49), seat (50) and filter

(52).

c. Cleaning and Inspection.

(1) Clean all parts thoroughly, using solvent

P-D-680, or equal.

(2) Inspect the piston (6, fig. 5-10) for nicks and

scratches.

(3) Inspect surface of the valve seat in the plunger

(13) for proper seating and outside signs of wear.

(4) Inspect the seat in the bronze plunger.

(5) Inspect valve seat in end of pilot valve seat

(29).

(6) Assemble pilot valve spool (28) inside pilot

valve seat (29) and place the steel balls (27) in their re-

spective seats and measure with a micrometer. Record

this measurement.

(7) Remove spool and place the steel balls in their

5 - 1 2 . Brake Applicator Valve and Differ-

respective seats and measure. Subtract the smaller di-

e n t i a l Pressure Switch.

mension. If difference is less than 0.004 inch, replace

the spool.

a. Removal.

(8) Inspect the nylon pins in the charging valve

(1) Remove the driver's floor plate and access

plug for wear or damage. These pins are used to keep

panel under the left fender (TM 10-3930-634-12).

the plugs from working loose.

(2) Refer to figure 5-9 and remove the differen-

tial pressure switch and brake applicator valve.

d. Reassembly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |