|

|||

|

|

|||

|

Page Title:

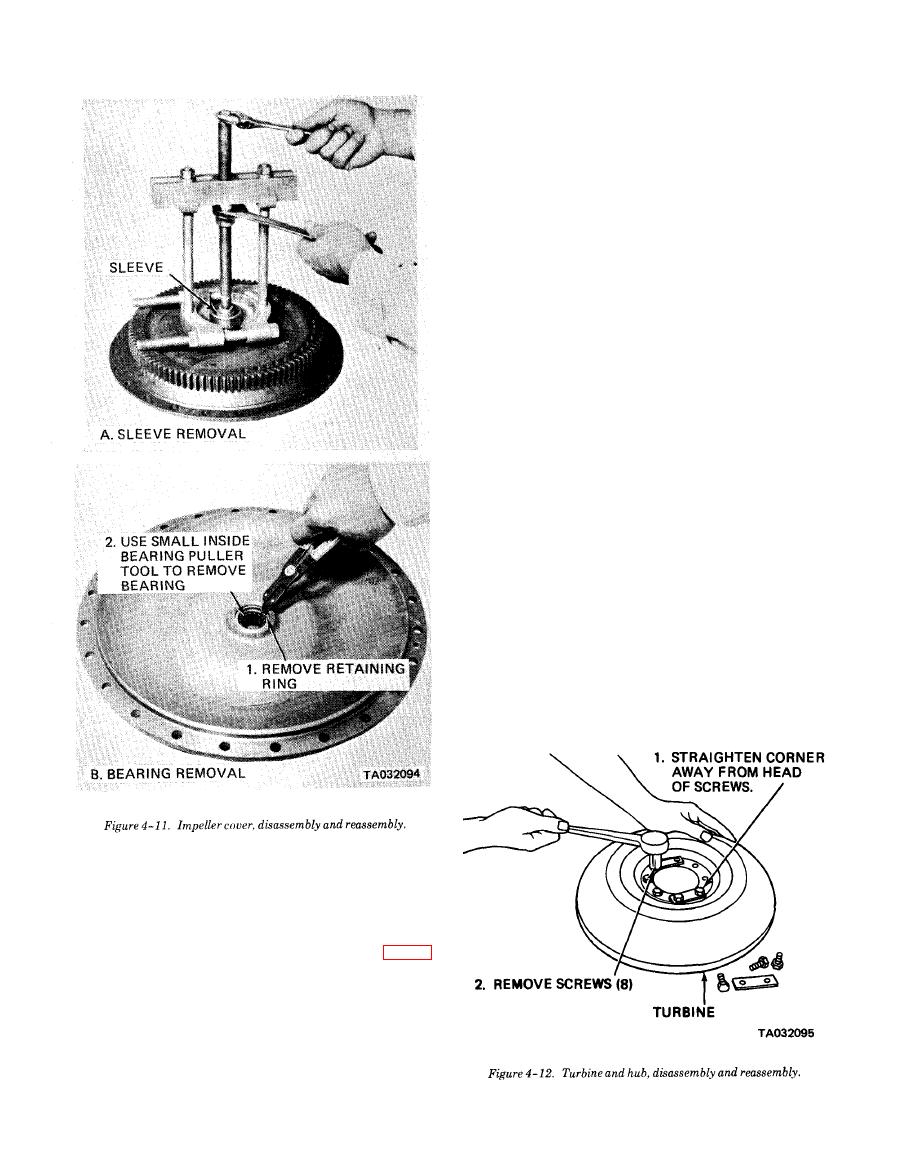

Figure 4-10. Turbine and hub, disassembly and reassembly |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

CAUTION

Do not use compressed air to dry bearings. Do

not spin bearings which have not been lubri-

cated.

(3) Clean passage ways of all tubes in converter

housing using a flexible wire brush.

e. Inspection and Repair.

(1) Inspect bearings, balls, and cages for wear,

chipping, or nicks. Replace if these defects are found.

( 2 ) Inspect bearing housings and shafts for

grooved, burred or galled condition that indicates the

bearing has been turning in its housing or on its shaft.

If the damage cannot be repaired with crocus cloth, re-

place the defective part.

(3) Discard all preformed packings and oil seals re-

moved during disassembly.

(4) Inspect gears for scuffed, nicked, burred or

broken teeth. If the defect cannot be removed with a

soft stone, replace the gear.

(5) Inspect gear teeth for wear that may have de-

stroyed the original tooth shape. If this condition is

found, replace the gear.

(6) Inspect the splined parts for stripped, twisted,

chipped or burred splines. Remove burrs with a soft

stone. Replace parts if other defects are found.

(7) Inspect all threaded parts for burred or dam-

aged threads. Chase damaged threads with correct size

tap or die. Replace all damaged hardware.

(8) Inspect the retaining rings for nicks, distortion

or excessive wear. Replace the part if any of these de-

fects are found. The retaining rings must snap tight in

their groove for proper functioning.

f. Reassembly.

NOTE

Immerse all parts in clean transmission oil

prior to reassembly. Use new seals and pack-

ings.

(c) Remove retaining ring (3).

from pump shaft (7).

(4) Converter Housing. Disassemble the converter

housing in numerical sequence as shown in figure

4-24.

d. Cleaning.

cleaning solvent P-D-680 and dry thoroughly.

(2) Clean bearings with volatile mineral spirits.

Lubricate bearings immediately after cleaning with

clean transmission oil.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |