|

|||

|

|

|||

|

Page Title:

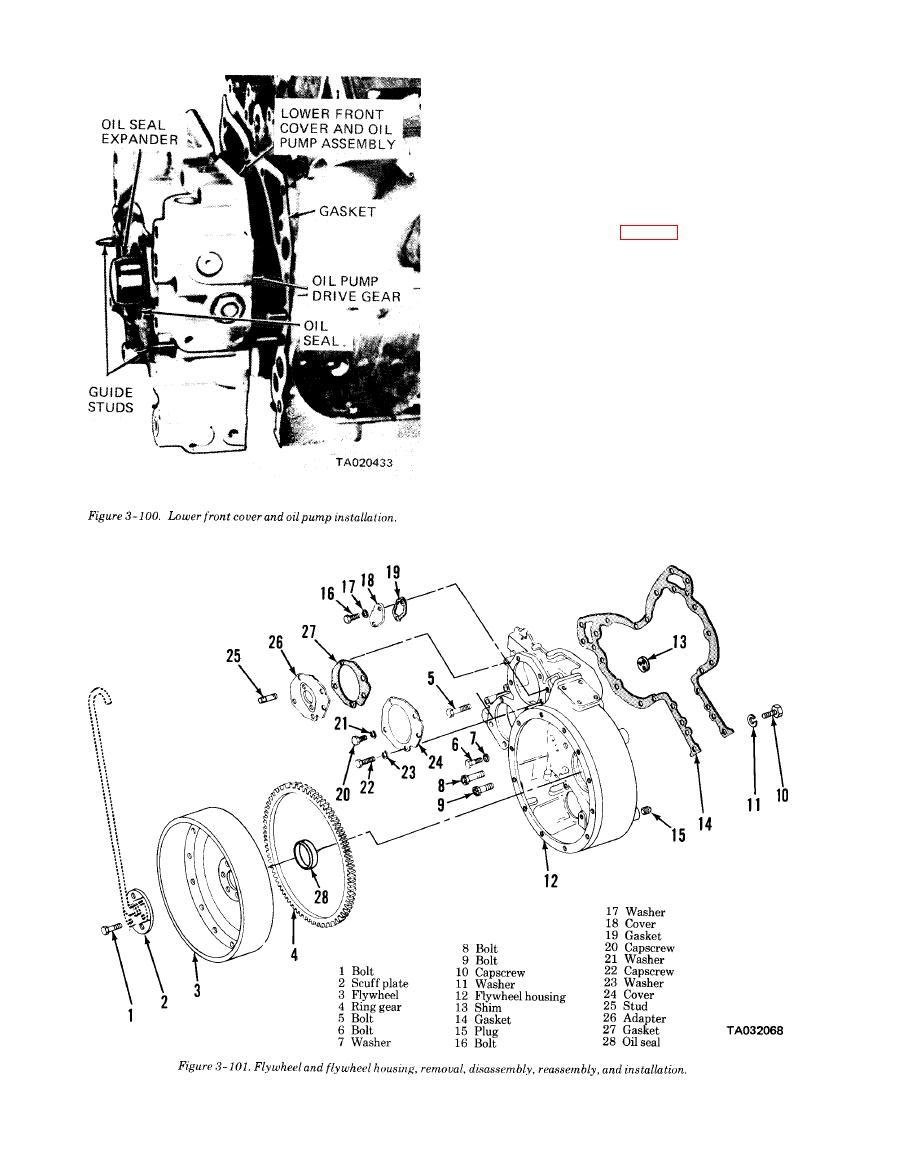

Figure 3-100.Lower front cover and oil pump installation |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

(4) Attach chain hoist to lifting tool to support the

flywheel.

(5) Remove the remaining flywheel attaching

bolt.

(6) Move upper end of tool back and forth to

loosen flywheel, then withdraw flywheel from crank-

shaft and flywheel housing.

c. Disassembly.

(1) If the ring gear (4, fig. 3-101) requires replace-

ment, support the flywheel, crankshaft side down, on

a solid flat surface on a hardwood block, which is

slightly smaller than the inside diameter of the ring

gear.

NOTE

Before removing the ring gear note the

chamfer, if any, on the gear teeth so the new

gear can be installed in the same position.

(2) Drive the ring gear off of the flywheel with a

suitable draft and hammer. Work around the circum-

ference of the ring gear to avoid binding of the gear on

the flywheel.

d. Cleaning and Inspection.

(1) Clean all parts with cleaning solvent P-D-680

and dry thoroughly.

(2) Inspect the flywheel for cracks, damaged

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |