|

|||

|

|

|||

|

Page Title:

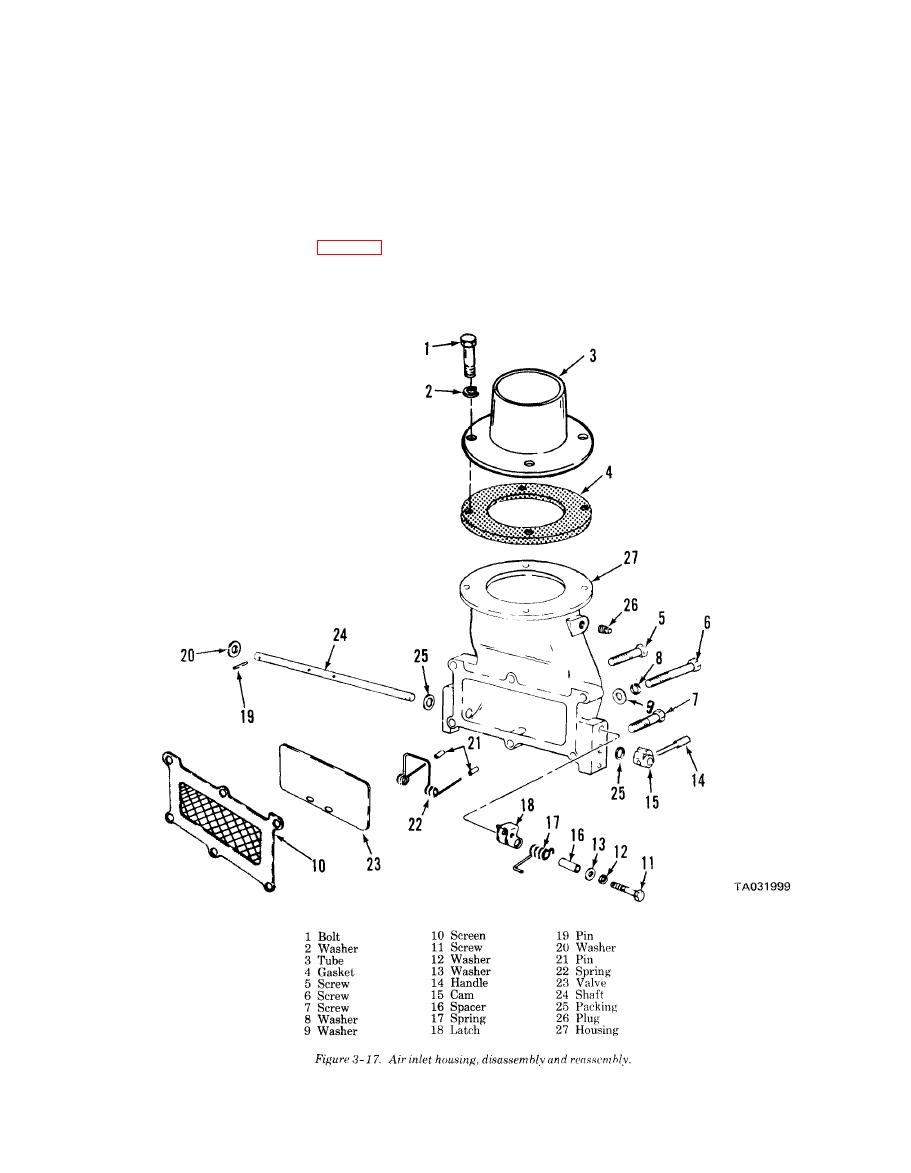

Figure 3-17. Air inlet housing, disassembly and reassembly |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

rotors or between rotors and housing, the blower must

ance. A combination of gear and rotor shaft bearing

surface wear will result in a decrease of rotor to hous-

be removed "and parts dressed clown to eliminate the

ing clearance.

interference or replaced.

(3) Seals are incorporated in each end of the

CAUTION

When inspecting the blower on an engine,

blower rotors and serve to prevent air leakage past the

with the engine running, keep your fingers

blower rotor shaft bearing surfaces, and to prevent oil

and clothing away from moving parts of the

blower and run the engine at low speed only.

from entering the rotor compartment.

b. Inspection (Blower Installed).

(3) Start engine and check for leaking oil seals.

Leaky oil seals are indicated by presence of oil on the

(1) Remove air inlet housing (para 3-13).

blower rotors or inside surfaces of the housing. Run

(2) Inspect the rotors for scratches, chips or other

the engine at low speed and direct a light into the rotor

abrasions. If burrs cause interference between the

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |