|

|||

|

|

|||

|

Page Title:

CHAPTER 2 DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM1O-393O-634-34

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

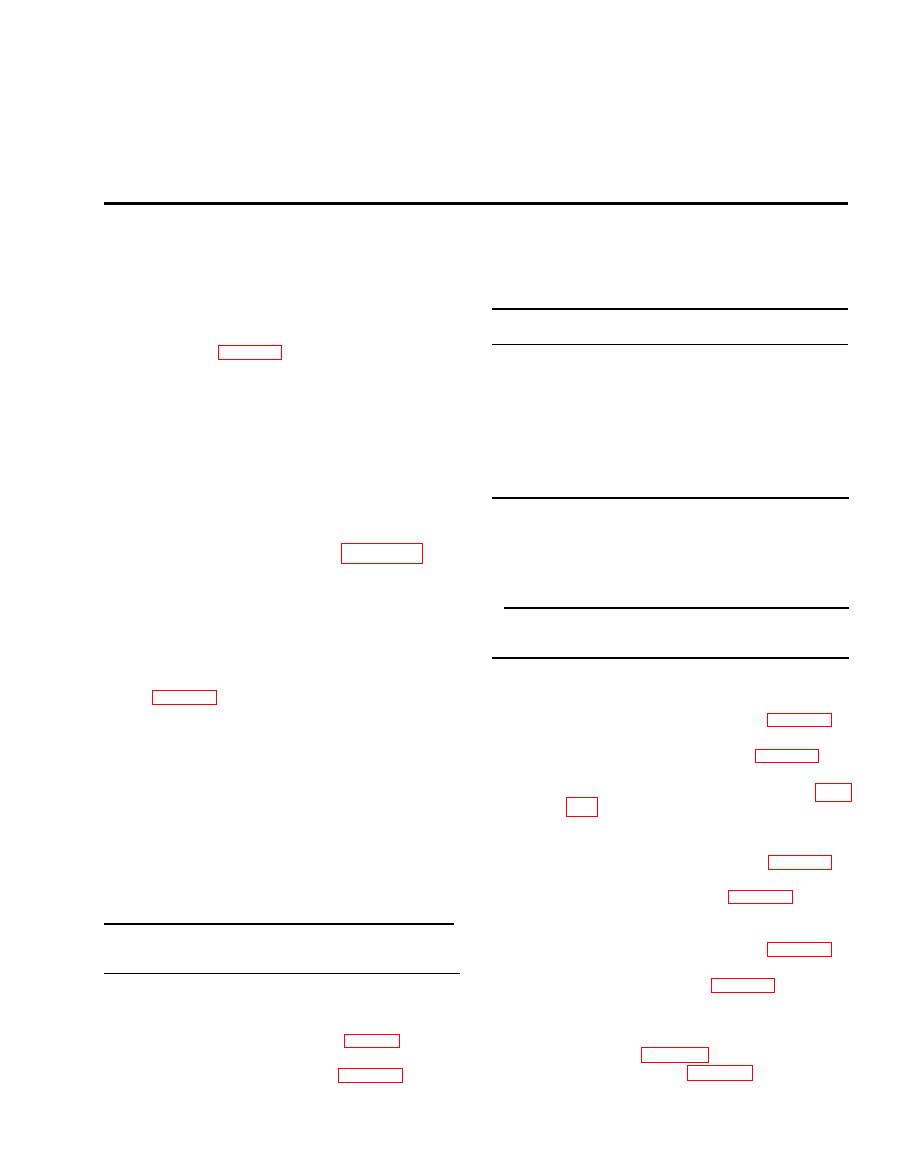

2-1. Special Tools and Equipment

The special tools required to perform direct support

Reference

NSN or

and general support maintenance on the forklift

Use

(para No.)

Reference No.

Item

trucks are listed in table 2-1 below. References indi-

Timing fuel

3-15

Injector tool

5220-00-387-9581

cating the use of these tools are listed in the table. No

injectors

timing

Charge accu-

5-13

3930-00-737-6430

Kit, pressure

special equipment is required by direct or general sup-

mulator

gage

port maintenance personnel to perform maintenance

Charge accu-

5-13

Regulator charg- 4910-00-861-2068

on the forklift truck.

mulator

ing Accumu-

lator

2-2. Maintenance Repair Parts

5120-00-009-8602

Kit

Adjust wheel

5-7

Repair parts and equipment are listed and illustrated

Socket, bearing

bearing nut

adjusting nut

in TM 10-3930-634-34P for direct and general sup-

port maintenance of the forklift truck.

Table 2-2. Troubleshooting-Continued

2-3. General

This section contains troubleshooting information for

MALFUNCTION

locating and correcting most of the troubles that may

TEST OR INSPECTION

develop on the forklift truck.

CORRECTIVE ACTION

2-4. Troubleshooting Chart

Step 3. Check for low compression caused by

broken or worn piston rings.

component, unit or system is followed by a list of tests

Replace defective piston rings (para 3-34).

or inspections that will help you to determine probable

Step 4. Check for defective fuel pump.

causes and corrective actions to take. You should per-

Repair or replace fuel pump (para 3-19).

form the tests, inspections and corrective actions in

Step 5. Check for defective starter circuit.

the order listed.

R e p a i r starter circuit continuity (para

b. This manual cannot list all malfunctions that

may occur, nor all tests or inspections and corrective

2.

ENGINE MISSES OR RUNS ERRATICALLY

actions. If a malfunction is not listed or is not correct-

Step 1. Check for defective fuel injector.

ed by the listed corrective action, notify your supervi-

Repair or replace fuel injector (para 3-18).

sor.

Step 2. Check for defective valves.

Repair or replace valves (para 3-25).

Table 2-2. Troubleshooting

Step 3. Check for low compression caused by

broken or worn piston rings.

MALFUNCTION

TEST OR INSPECTION

Replace defective piston rings (para 3-34).

CORRECTIVE ACTION

Step 4. Check for inadequate fuel flow.

Make a fuel flow test (para 3-19).

ENGINE HARD TO START OR FAILS TO

1.

3.

ENGINE LACKS POWER

START.

Step 1. Check for low air box pressure.

Step 1. Check for defective starter motor.

Replace air cleaner element or clean blow-

Repair or replace starter (para 3-9).

er screen (para 3-13), or replace engine

Step 2. Check for leaking or defective valves.

end plate gaskets (para 3-39).

Repair or replace valves (para 3-25).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |