|

|||

|

|

|||

|

Page Title:

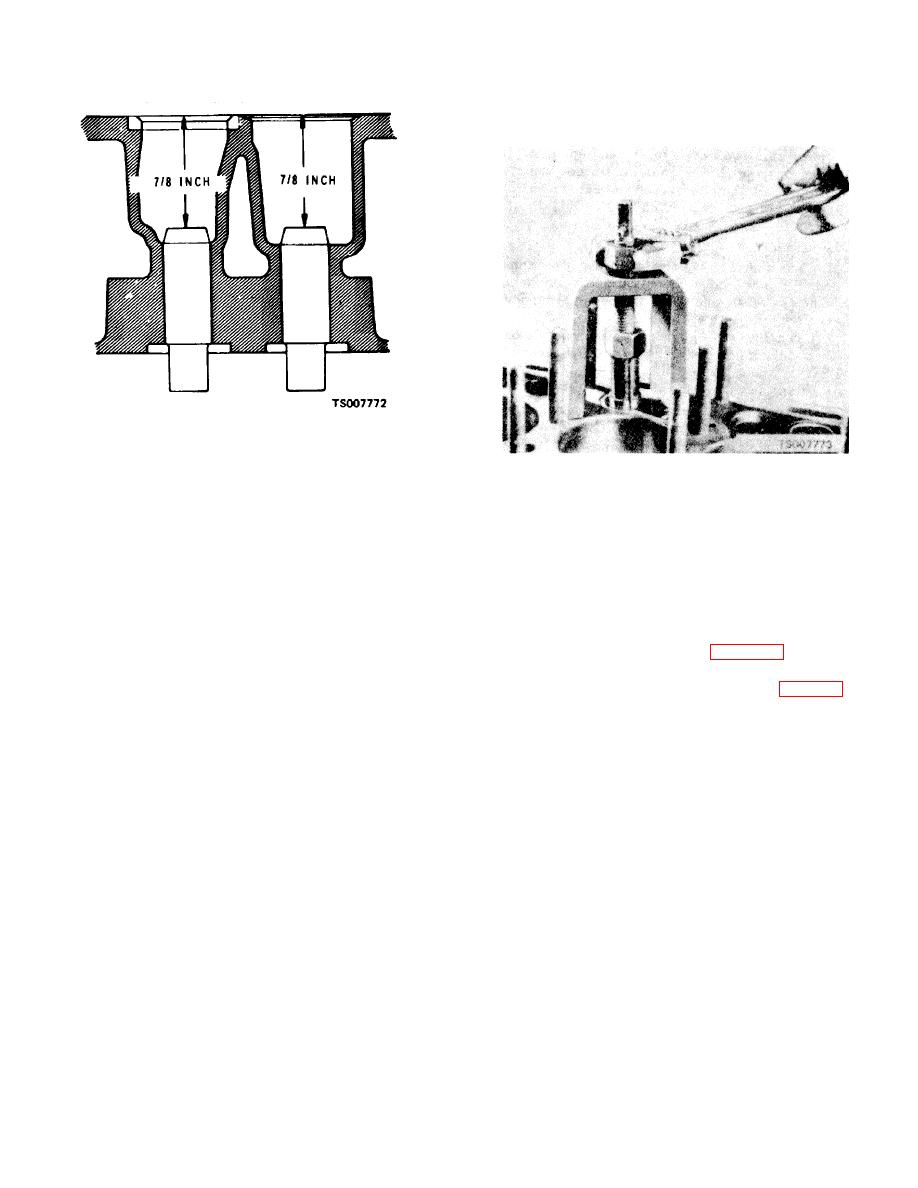

Figure 9-8. Valve Guide Installation Dimensions. |

|

||

| ||||||||||

|

|

TM 10-3930-632-34

resting against the bottom of the bore. Roll or peen the

valve seat in-place.

Figure 9-8. Valve Guide Installation Dimensions.

CAUTION

Figure 9-9. Pulling Valve Seat Insert.

Do not attempt to ream the valve guides after

seating them. Guides are pre-reamed and

h.

Check the valve springs for cracks and

coated. Further reaming will remove the coating.

distortion. Test compression strength with a spring

tester. Compression, strength must be as follows:

g.

Check the exhaust seat inserts for cracks or

loose mounting. Pull out faulty valve seat inserts (fig. 9-

Length

Load (minimum)

9). Replace valve seats with new 0.010 inch oversized

1-33/64 in. (closed

42 pounds

valve seats. Counterbore the valve seats to a diameter of

1-15/64 in. (open)

86 pounds

1.1255 to 1.1245 inches. This will provide the required

press fit. Counterbore deeply enough so that the boring

I.

Grind the valve seats {fig. 9-10). The seat

tool will clean up the bottom of the bore to assure proper

angle of the intake valves in 45. The seat angle of the

heat conduction from the valve insert. Chill the valve

exhaust valve is 45. Use a dial indicator (fig. 9-11) to

seats in dry ice for 20 minutes. Install the valve seat in

check the valve seat for runout. The total indicator

place with a piloted driver using an arbor press or by

reading must not exceed 0.002 inch. Clean the valve

applying light blows with a hammer until the valve seat is

seat and exceed 0.002 surrounding area thoroughly after

grinding.

9-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |