|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

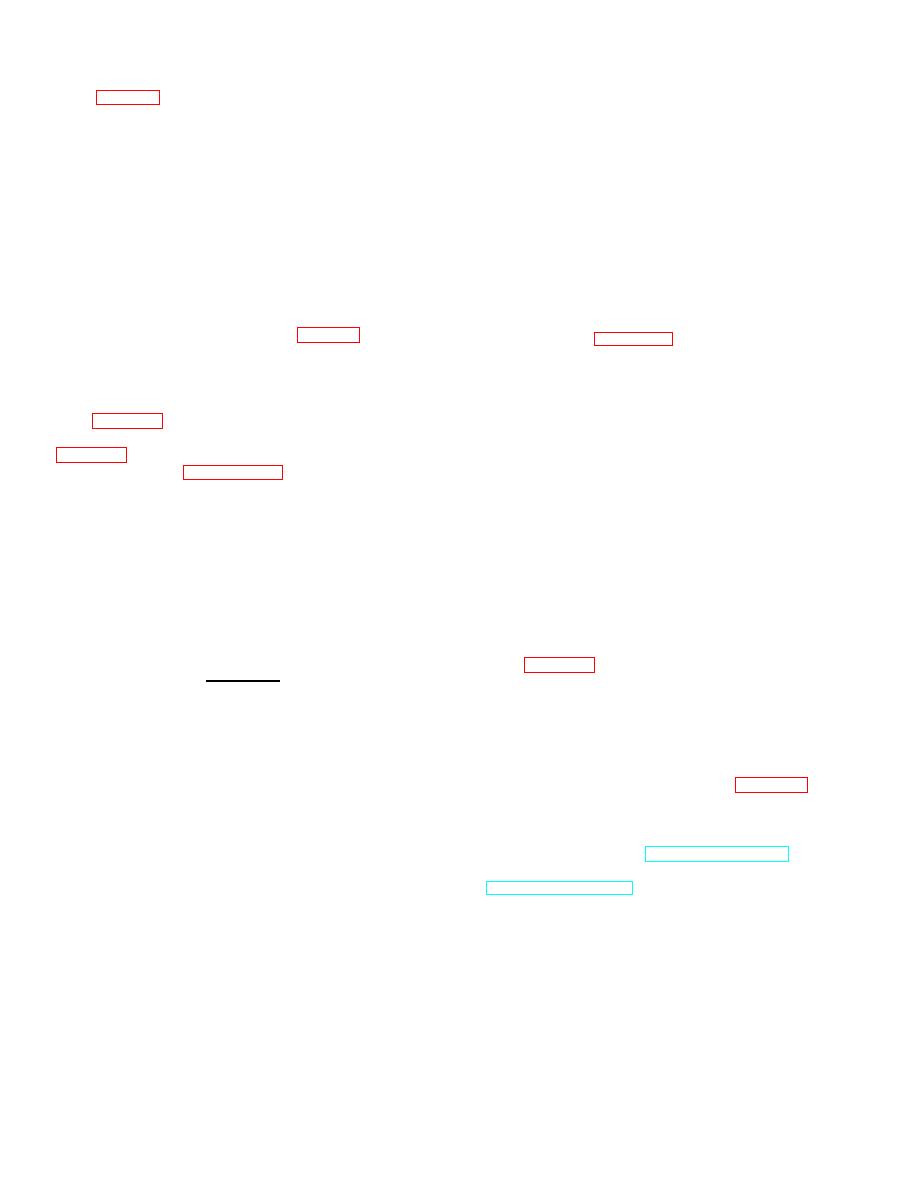

KEY to figure 6-3:

with crocus cloth. If the burrs or scores are too deep to

1.

Spring

11.

Surge screw

remove in this manner, replace the part.

2.

Nut

12.

Screw

d.

Inspect the drive assembly for a cracked ball

3.

Lockwasher

13.

Spring

retainer; worn, pitted or scored balls; distortion; or other

4.

Adjusting bolt

14.

Plug

damage. Replace a damaged drive assembly.

5.

Nut

15.

Pin

e.

Check the needle bearings for smooth

6.

Bracket

16.

Lever

operation; replace sticking or rough operating bearings.

7.

Race assembly

17.

Governor arm

f.

Inspect the shaft for wear, scoring, and

8.

Nut

18.

Dust seal

9.

Drive assembly

19.

Oil seal

distortion; replace if damaged.

10.

Nut

20.

Needle bearing

g.

Inspect all other governor parts for cracks,

scoring, wear or distortion; replace damaged parts.

e.

Disconnect the hose to the engine oil filter

from the gear cover. Drain the oil from the filter and

6-11.

Reassembly and Installation

f.

Remove the hex locknuts (fig. 2-3) and lower

a.

Refer to figure 6-3 and reassemble and install

support pads from the stud of the engine assembly. Hoist

the governor assembly. Install the rotating parts (7

the engine just enough to raise the upper support pad off

through 9) on the timing gear and camshaft. Install the

the frame. Block the engine in this position.

governor arm and lever and associated parts (14 through

g.

Remove the hydraulic pump and mounting

20) on the gear cover.

plate (para 9-19).

b.

When installing the needle bearings (20) in the

h.

Remove the gear cover from the engine block

bore of the gear cover, tap them into position with a

driver and light hammer until there is clearance for the oil

I.

Refer to figure 6-3 and remove and

seal (19) and dust seal (18). Install the oil seal and dust

disassemble the governor assembly.

seal.

c.

When installing the surge screw (11), turn it

NOTE

into the cover about one-fourth of its length as a

Do not remove the drive screws (12) and spring (13)

preliminary adjustment.

unless obviously damaged.

d.

Install the adjusting bolt (4), nuts (2) and

lockwasher (3) on the bracket (6) so that an equal

j.

If the needle bearings (20) are damaged, use

amount of threads are visible on each side of the nuts.

a rod of slightly smaller diameter than the gear housing

This is a preliminary adjustment. Install the spring (1)

hole and drive the dust seal (18), oil seal (19!, and

between the adjusting bolt and governor arm (17).

needle bearings (20) out of the gear cover.

e.

Install the hydraulic pump and pump mounting

plate (para 9-19).

WARNING

f.

Lower the fan end of the engine so that it is

resting on the truck frame. Install the bottom support

Dry cleaning solvent, P-D-680, used to clean

pads and nuts.

parts is potentially dangerous to personnel and

g.

Connect the hose from the engine oil filter to

property. Avoid repeated and prolonged skin

the gear cover. Fill the engine crankcase (LO 10-3930-

contact. Do not use near open flame or

632-12).

excessive heat. Flash point of solvent is 100F. -

h.

Install the crankshaft pulley (para 9-21, e ).

138 F. (39 C. - 59 C.).

I.

Install the fan and generator V-belts (TM 10-

3930-632-12).

6-10.

Cleaning, Inspection and Repair

j.

Connect the governor linkage clevises to the

governor adjusting arm (TM 10-3930-632-12).

a.

Discard the seals.

k.

Install the muffler, radiator, and counterweight

b.

Clean all parts of the governor in cleaning

(TM 10-3930-632-12).

solvent P-D-680 and dry with compressed air. Dip the

l.

Adjust the governor linkage (TM 10-3930-632-

needle bearings and drive assembly in engine oil.

12).

c.

Inspect the race assembly for wear, scoring,

distortion, cracks, breaks, or other damage; replace

damaged parts Remove burrs and scoring by lapping

Section IV. FUEL TANK

6-12.

General

6-13.

Repair

The fuel tank is built into the frame at the left side of

The fuel tank is built into the left frame member of

the truck. It is not removable.

the lift truck. If fuel tank leaks or other damage

6-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |