|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

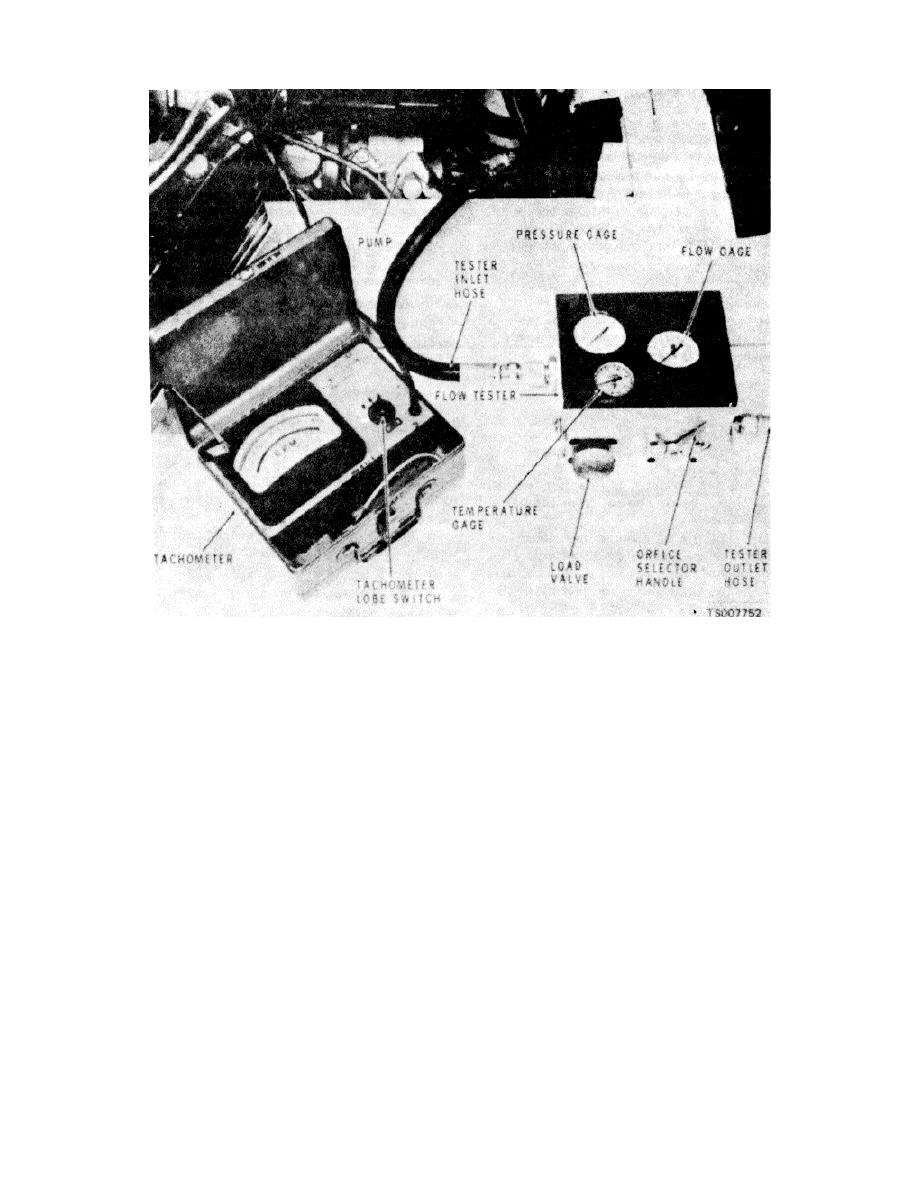

Figure 4-3. Hydraulic Pump Test Setup.

a. Connect tachometer. Set lobe switch to 4-lobe

f.

Start the vehicle engine and set the engine

position.

b. Disconnect pressure hose from hydraulic pump

speed at 1450 RPM.

g. Bring the hydraulic oil to the test temperature of

and plug hose end. Connect one end of test hydraulic

130F by gradually applying the load valve (turning

pressure hose to hydraulic pump and other end to inlet

side of flow tester. Be sure all connections are tight.

clockwise) until the fluid pressure reaches 1000 PSI.

c. Disconnect reservoir return line hose at the

hydraulic control valve and plug the valve opening.

CAUTION

Connect one end of the test return hose to the reservoir

Apply load valve pressure gradually as rapid

return hose and the other end to the outlet side of the

application of valve can result in "blowing out"

flow tester. Be sure all connections are tight.

the tester relief plug.

d. Set flow tester orifice selector handle on 0-30

GPM position (maximum clockwise).

h. After the hydraulic oil is brought to test

e. Turn tester load valve to fully open position by

temperature and the flow gage needle is stabilized,

turning all the way to the left (maximum

gradually reduce pressure at tester to 100 PSI by turning

counterclockwise).

load valve to the left (counterclockwise). Turn orifice

selector handle to the left (10 gal scale), stabilize flow

CAUTION

gage needle and record flow reading at 100 PSI tester

Load valve is capable of extremely high pressure

pressure. Flow reading should be 6 to 6.5 GPM.

and must be in the fully open position before

starting test. Do not exceed prescribed test

pressures when conducting test.

4-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |