|

|||

|

|

|||

|

Page Title:

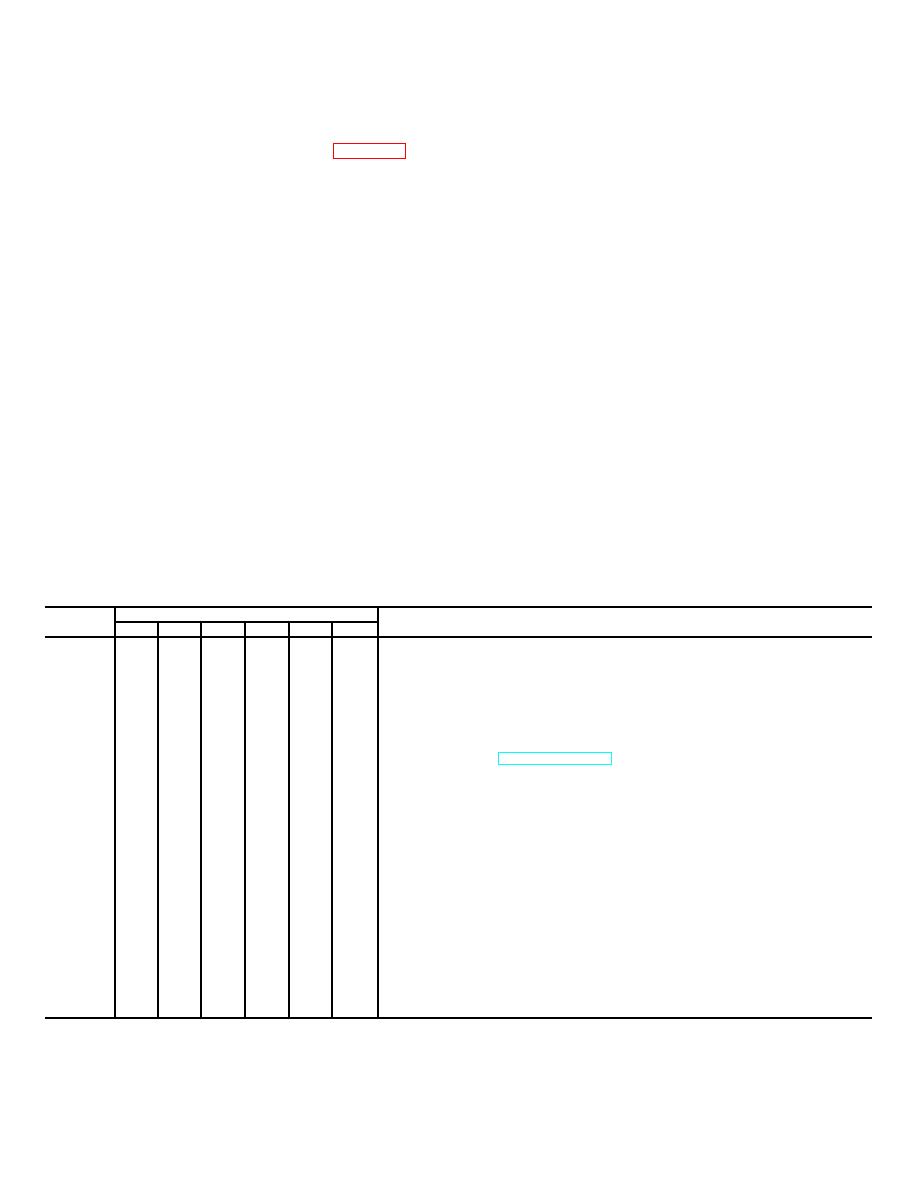

Table 4-1. Organizational Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 10-3930-632-12

e. You should know how fluid leaks affect the

(6) Do the (MI) checks and services when

the mileage of the vehicle reaches the amount listed.

status of your equipment. Learn and be familiar with the

b. If the fork lift truck doesn't work properly and

following definitions of the types/classes of leakage.

Leadage definitions for PMCS are:

you can't see what is wrong, refer to table 4-2 for

CLASS I

Seepage of fluid (indicated by

troubleshooting instructions.

WARNING

wetness or discoloration) not great

enough to form drops.

Drycleaning solvent SD-2, used to clean

CLASS II

Leakage of fluid great enough to

parts, is potentially dangerous to personnel

form drops but not enough to

and property. Do not use near open flame

cause drops to drip from the item

or excessive heat. Flash point of solvent is

being checked/inspected

138F.

c. Make cleanup a part of your preventive

CLASS III Leakage of fluid great enough to

form drops that fall from the item

maintenance. Dirt, grease, oil, and debris may cover up

being checked/inspected.

a serious problem. Use drycleaning solvent (SD-2) to

CAUTION

clean metal surfaces. Wipe off excess grease and

Equipment operation is allowable with minor

spilled oil. Use soap and water when you clean rubber

leakage (Class I or II).

Of course,

or plastic material.

d. Watch for and correct anything that might

consideration must be given to the fluid

capacity

in

the

item/system

being

cause a problem with the equipment. Some things you

checked/inspected. When in doubt, notify

should watch for are:

your supervisor.

(1) Bolts, nuts, and screws that are loose,

When operating with Class I or II leaks,

missing, bent, or broken.

continue to check fluid levels as required by

(2) Welds that are bad or broken.

the PMCS.

(3) Electric wires and connectors that are

Class III leaks should be corrected before

bare, broken, or loose.

releasing equipment for operation.

(4) Hoses and fluid lines that lead, or show

signs of damage or wear.

Table 4-1. Organizational Preventive Maintenance Checks and Services

Q-Quarterly

S-Semiannually

A-Annually

B-Biennially H-Hours

M-Miles

ITEM

INTERVAL

ITEM TO BE INSPECTED

NO.

Q

S

A

B

H

M

PROCEDURE: Check for and repair, fill or adjust as needed.

NOTE

Perform Operator/Crew PMCS prior to or in conjunction with Organizational PMCS if:

a. There is a delay between the daily operation of the equipment and the Organization

PMCS.

b. Regular operator is not assisting/participating.

ENGINE OIL

250

1

Drain oil and replace engine oil filter. Refill with enough oil to bring oil level up to FULL

mark on dipstick (ref. LO 10-3930-632-12).

FUEL FILTER

250

2

Clean bowl and element.

ENGINE TUNE-UP

3

250

a. Adjust or replace ignition points (point gap should be .022 inch).

250

b. Check spark plugs and replace as necessary (gap should be .030 inch).

250

c. Clean PCV valve.

250

d. Check timing of engine.

VEE BELTS

4

250

Check belts for proper tension. Should be 1/2 to 3/4 inch deflection at point midway

between pulleys under approximately 25 pounds of force.

BATTERY

250

5

Check specific gravity and charge as necessary. Clean terminals and insure all

connections are tight. Inspect battery for corrosion. (Ref. TM 9-6140-200-14.)

BRAKE AND INCHING MASTER CYLINDERS

250

6

Check level of fluid. Fluid should be within 114 inch of top of reservoir.

STEERING DRAG LINK AND TIE ROD

7

250

Lubricate/check steering mechanism to insure it operates freely without binding.

Change 1 4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |