|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

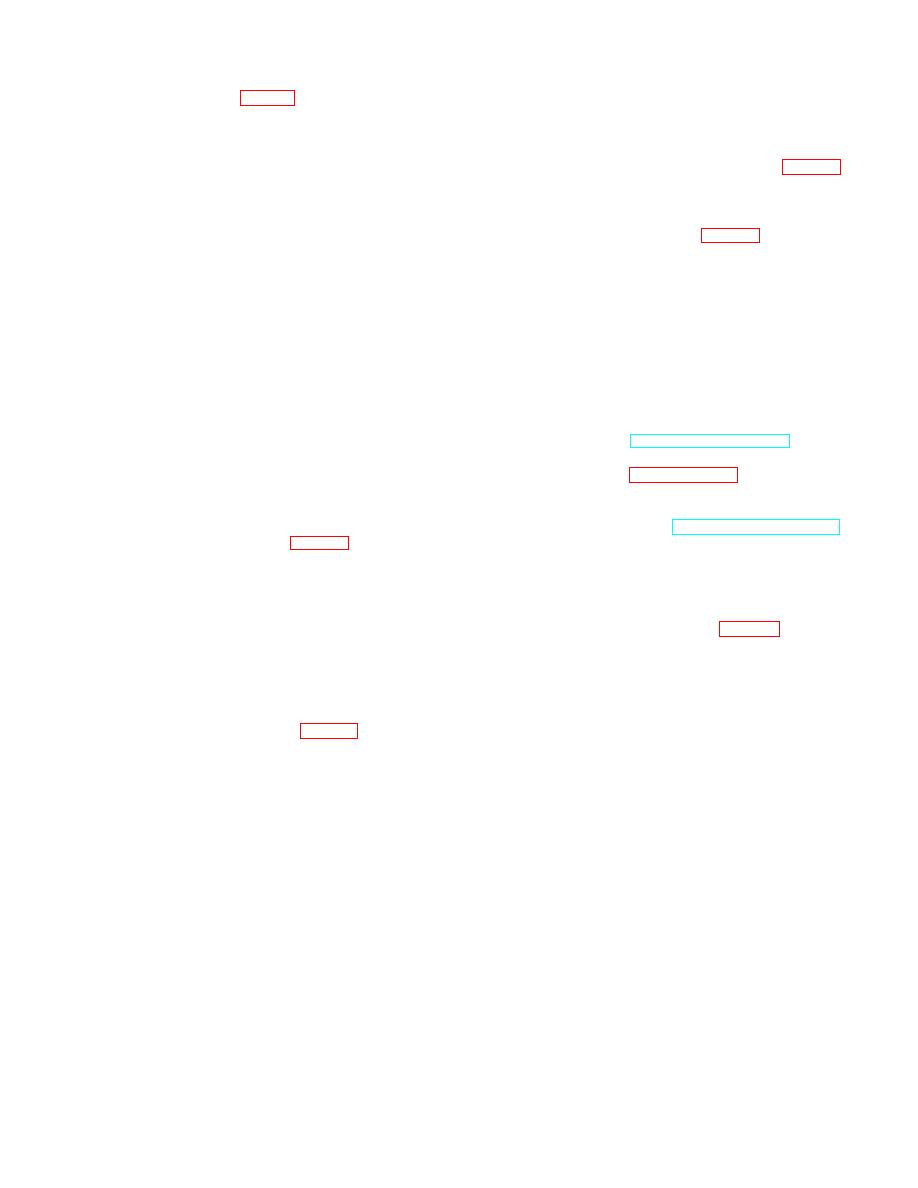

KEY to fig. 4-4:

inches (107.9 mm). Length with 20.85 pounds of

1. Fitting bolt

17. Brake pedal

pressure applied should be 2.812 inches (71.4 m1n).

2. Gasket

18. Lubrication fitting

(4) Replace worn and damaged parts.

d. Assembly.

3. Gasket

19. Brake pad

4. Fitting

20. Sleeve bearing

(1) Press new sleeve bearings (20, fig. 4-4) in

5. Brake line

21. Screw

bore of brake pedal. Install lubrication fitting (18).

6. Brake line

22. Lock washer

(2) Install brake pad (19) on brake pedal.

e. Installation.

7. Brake line

23. Nut

8. Tee

24. Bumper

(1) Install support (28, fig. 4-4) in position on

9. Cotter pin

25. Bracket

left wall of frame and secure support with screws (26)

10. Clevis pin

26. Screw

and lock washers (27).

11. Clevis

27. Lock washer

(2) If removed, install one retaining ring (16) in

12. Jam nut

28. Support

groove of shaft. Slide brake pedal assembly on shaft

13. Spring retainer 29. Switch

and secure with second retaining ring.

14. Spring retainer 30. Screw

(3) Install bracket (25) on front frame and

15. Spring

31. Lock washer

secure with screws (21) and lock washers (22). Install

16. Retaining ring 32. Nut

bumper (24) in bracket and secure with two jam nuts

(5) Remove retaining ring (16) and remove

(23).

pedal assembly from support.

(4) Aline clevis (11) with holes in brake pedal

(6) Remove nuts (23) and remove bumper (24).

and secure with clevis pin (10) and cotter pin (9).

If necessary to replace bracket, remove screws (21) and

(5) Refer to TM 10-3930-631-12 and install

lock washers (22) and remove bracket (25).

brake master cylinder.

(7) Check support (28) and if worn or damaged

(6) Refer to paragraph 2-9 and install brake

remove screws (26) and lock washers (27) and remove

lines.

support from frame.

4-5. Master Cylinder

b. Disassembly.

a. Removal. Refer to TM 10-3930-631-12 and

(1) Remove pedal pad (19, fig. 4-4) if worn or

remove the master cylinder.

damaged.

b. Disassembly.

(2) Remove lubrication fitting (18) from pedal.

(1) Secure master cylinder assembly in a vise.

(3) Use a suitable press and press two sleeve

To prevent damage or distortion of cylinder body do not

bearings (20) from pedal.

overtighten vise.

c. Cleaning, Inspection and Repair.

(2) Remove filler cap (1, fig. 4-5) and gasket

(1) Clean all parts except rubber bumper in

(2). Remove fittings (3 and 5) and gaskets (4 and 6).

cleaning compound, solvent (Fed. Spec. P-D-680) and

dry thoroughly.

(2) Inspect parts for wear, cracks and other

damage.

(3) Check return spring (15, fig. 4-4) for cracks

and damage. Free length should be 4.25

4-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |