|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

solvent (Fed. Spec. P-D-680). Dry thoroughly with

(6) Install bearing cups (32) in carrier.

compressed air.

Install bearing cones (33) on differential case.

(2) Inspect all parts for cracks, chips, wear

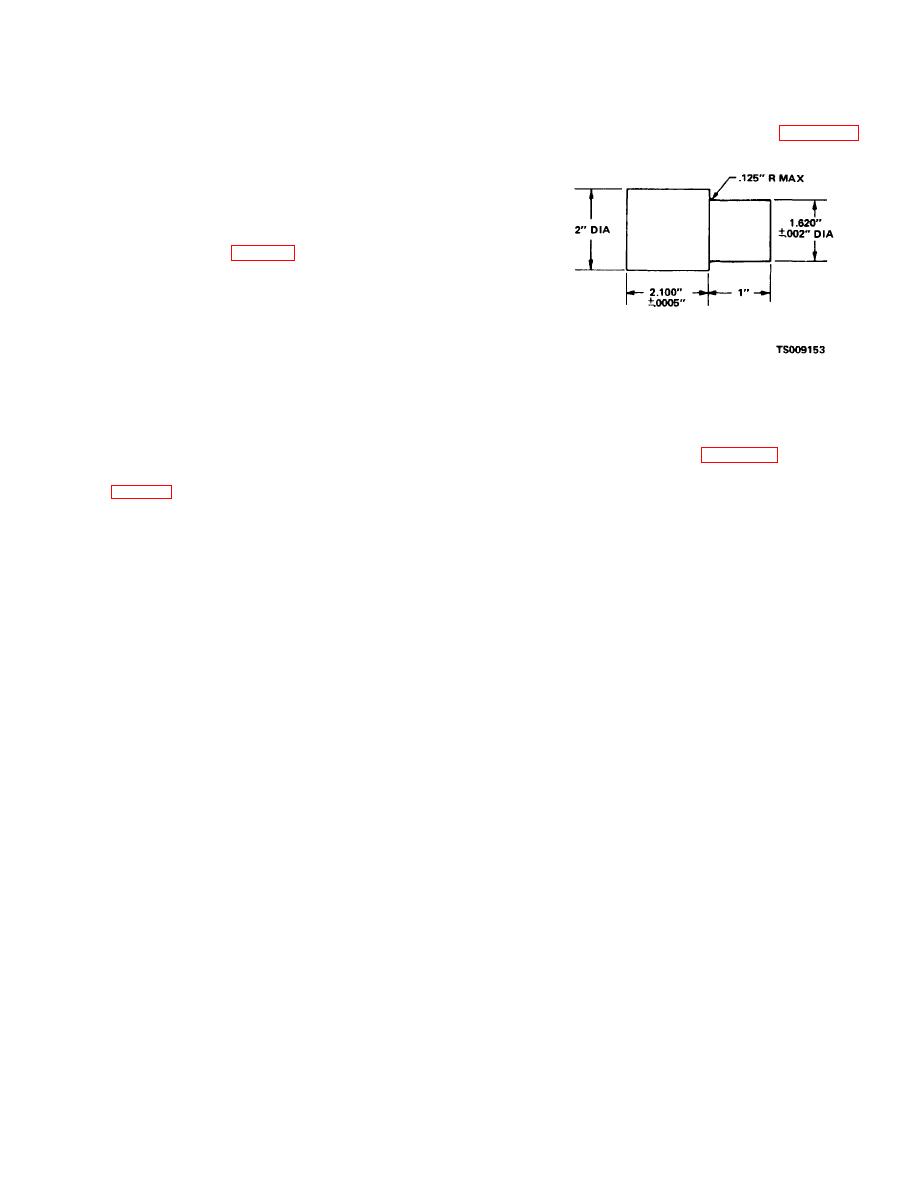

(7) Fabricate a tool as shown in figure 3-12.

and damage.

(3) Pinion and ring gear must be replaced

as a set.

(4) Replace all oil seals and gaskets.

Replace all damaged, worn, or cracked parts.

d. Assembly.

(1) Install pin (9, fig. 3-11) in flanged case

half. Position pinion shaft (10), bevel gears (7) and

thrust washers (8) in flange case half (3).

(2) Install pinion gears (6) and thrust

washers (5) and pinion shaft (10). Mesh pinion

gears with bevel gear and install on flanged case

half.

(3) Install thrust washer and bevel gear (7)

Figure 3-12. Fabricated tool for measuring shims.

in plain case half (4). Aline case halves and install

plain case half on flanged case half.

(8) Install front bearing cup (26), without

(4) Secure case halves with screws (2) and

shims, on fabricated tool and install tool and bearing

lock (1). Tighten screws to a torque of 17-25 pound

in cup in carrier as shown in figure 3-13.

feet (2.3-3.4 m-kg). Lock screws with locks.

(5) Press front and rear bearing cups (20

and 27, fig. 3-8) in carrier. Cups must be firmly

seated.

3-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |