|

|||

|

|

|||

|

Page Title:

Section III. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT |

|

||

| ||||||||||

|

|

TM 10-3930-631-12

c. Battery.

(1) Open battery compartment and remove

CAUTION

side panels.

Do not reverse polarity of battery cables.

(2) Using a hoist of sufficient capacity, lift

(4) Service and charge battery as described

battery into compartment.

(3) Connect battery receptacle as shown in

Section II. MOVEMENT TO A NEW WORKSITE

another carrier, refer to figure 4-1 and remove the forks.

4-3. Dismantling for Movement

4-4. Reinstallation after Movement

The only component that may require dismantling

for movement is the forks. If necessary to conserve

If forks were removed to transport the lift truck,

space when transporting the lift truck by means of

refer to figure 4-1 and install the forks on the carriage.

Section III. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

perform organizational maintenance of the fork lift truck.

4-5. Tools and Equipment

4-7. Maintenance Repair Parts

Tools, equipment and repair parts issued with or

authorized for the fork lift truck are listed in the basic

Repair parts and equipment are listed and

issue items list, appendix C.

illustrated in the repair parts and special tools list (TM

10-3930-631-20P) for the fork lift truck.

4-6. Special Tools and Equipment

No special tools and equipment are required to

Section IV. LUBRICATION INSTRUCTIONS

4-8. General

These paragraphs contain lubrication instructions

which are supplemental to and not specifically covered in

the lubrication order.

4-9. Hydraulic Filter

a. Replacement of the filter element is required at

regular intervals.

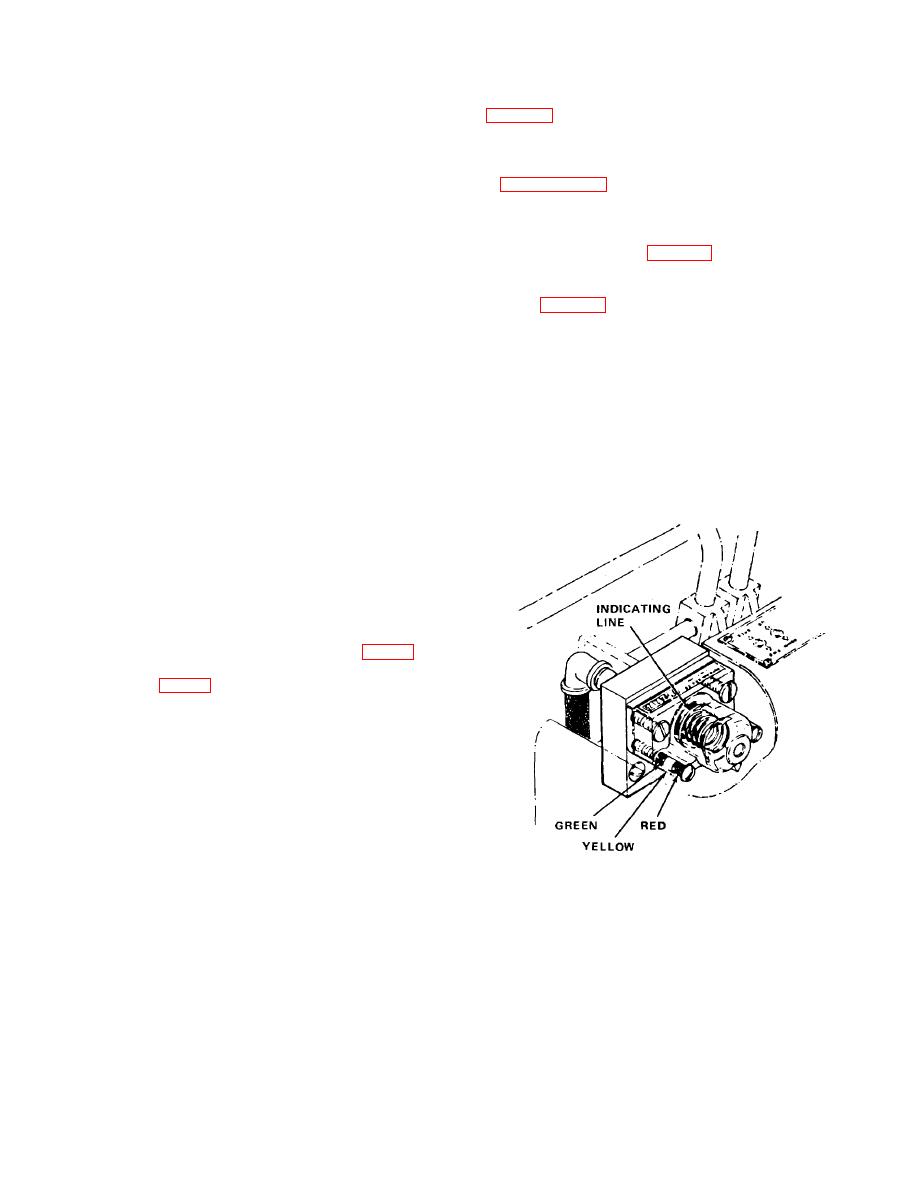

b. A hydraulic filter element indicator (fig. 4-2) is

located to the right of the control valve handles. The

indicating line (fig. 4-2) should be in line with the green

band. This indicates filter element is operating properly.

If indicating line is in line with yellow band element is

becoming contaminated and should be changed at

earliest convenience.

When white indicating line

reaches any portion of red band, change filter element at

once.

Figure 4-2. Hydraulic filter element indicator,

installed view.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |