|

|||

|

|

|||

|

Page Title:

Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

(8) Remove the bushing (9) if it is excessively

or unevenly worn.

(9) Remove the rings (10 and 11) if they must

be replaced.

b. Cleaning, Inspection and Repair.

Caution: Do not use cleaning solvents

containing chemicals which will react with

aluminum alloy.

(1) Clean all parts with a cleaning solvent and

dry with compressed air.

(2) Use the following procedure to check for

piston wear.

(a) Inspect the piston skirt for score marks

or other indications of improper piston clearance.

Inspect the inside of the piston for cracks. Replace

any piston that is scored or cracked.

(b) Check the piston for wear by inserting it

into its respective cylinder sleeve and measuring the

clearance between the piston and the sleeve. Make

sure that the piston is inserted into the sleeve far

enough so the measurement is taken in the area of

the piston ring travel. The specified clearance is

f r o m 0 . 0 0 2 3 - 0 . 0 0 4 8 i n c h , measured at the

bottom of the piston skirt and at right angles to the

piston pin. The piston skirt diameter of a new

piston is 3.4365-3.4385 inches. measured at the

right angles to the piston pin. The inside diameter

of a new cylinder sleeve is 3.4379-3.4385 inches.

T h e piston or cylinder sleeve, or both, must be

replaced if the clearance exceeds 0.008 inch.

(c) If the piston is to be replaced, new rings

must be used.

(3) Use the following procedure to inspect the

piston rings.

(a) Select the rings to be installed on each

piston and insert them one at a time into the

cylinder sleeve in which they are to operate. Use a

piston to push the ring squarely into the cylinder

sleeve so that it is parallel with the top of the

cylinder block. Push the ring far enough down into

the bore of the cylinder sleeve to be on the ring

travel area.

(b) Measure the ring gap with a feeler gage.

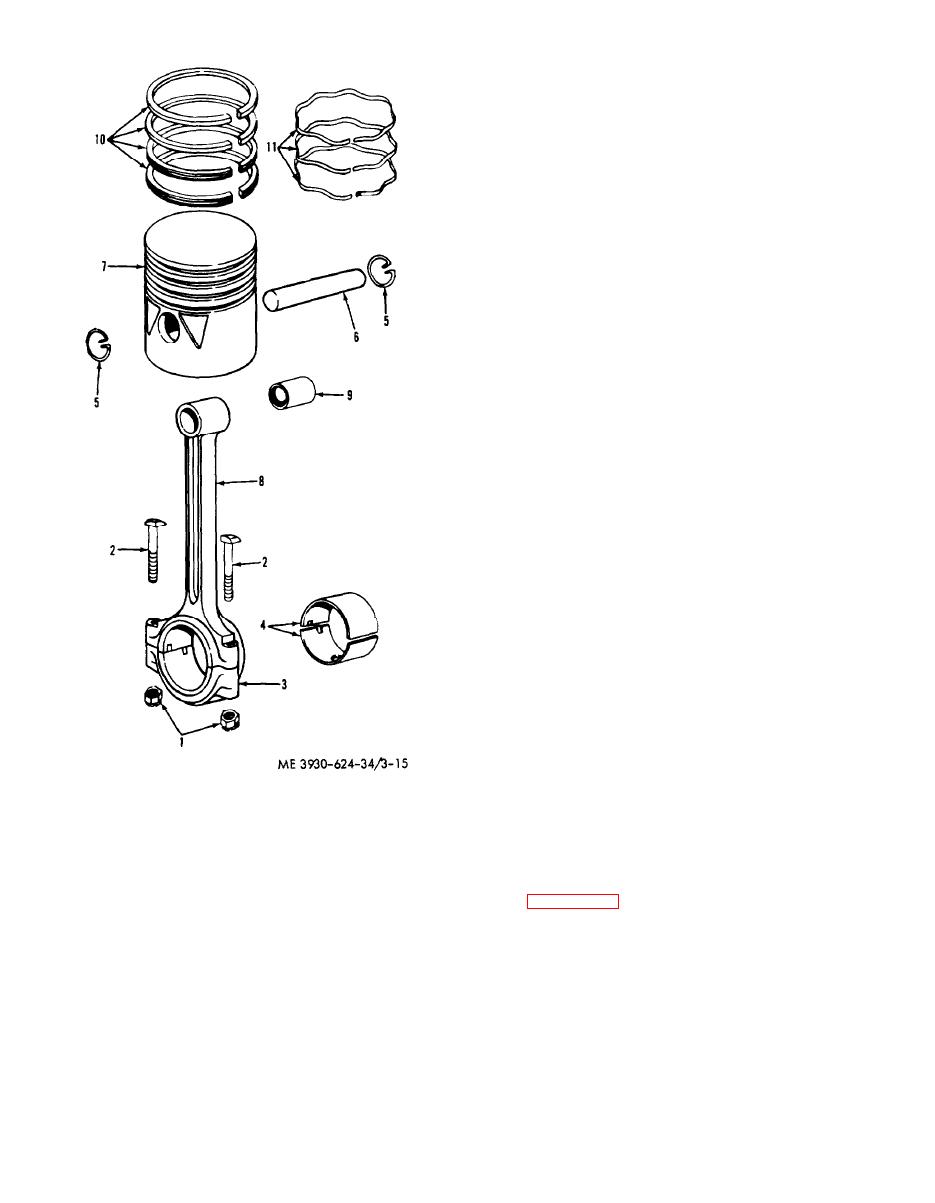

1. Nut

7. Piston

The ring gap specification for all rings is 0.011 inch

2. Capscrew

8. Connecting rod

3. Bearing cap

minimum. If necessary, file the ring ends with a

9. Bushing

4. Liner

10. Ring

fine cut file to obtain the correct clearance.

5. Retaining ring

11. Ring

(c) Measure the ring to groove clearance

6. Pin

(top of the ring to top of the groove in the piston).

Figure 3-15. Piston and connecting rod.

Refer to figure 3-16. Specified clearances are as

(6) Remove the liners (4) if they are to be

follows: top-compression 0.002-0.004 inch,

replaced.

second-compression 0.0015-0.0035 inch. third-oil

(7) Remove the piston pin retaining rings (5).

control 0.0015-0.0035 inch, and fourth-oil control

Drive out the pin (6) using a wood block or brass

0.001-0.003 inch.

drift.

3-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |