|

|||

|

|

|||

|

Page Title:

Section XIII. MAINTENANCE OF SHAFTS AND AXLES |

|

||

| ||||||||||

|

|

Section XIII. MAINTENANCE OF SHAFTS AND AXLES

b. Servicing. To pack the universal joints with

4-46. Propeller Shafts

lubricant proceed with the following steps.

a. Removal.

Caution: All parts of the universal joint and

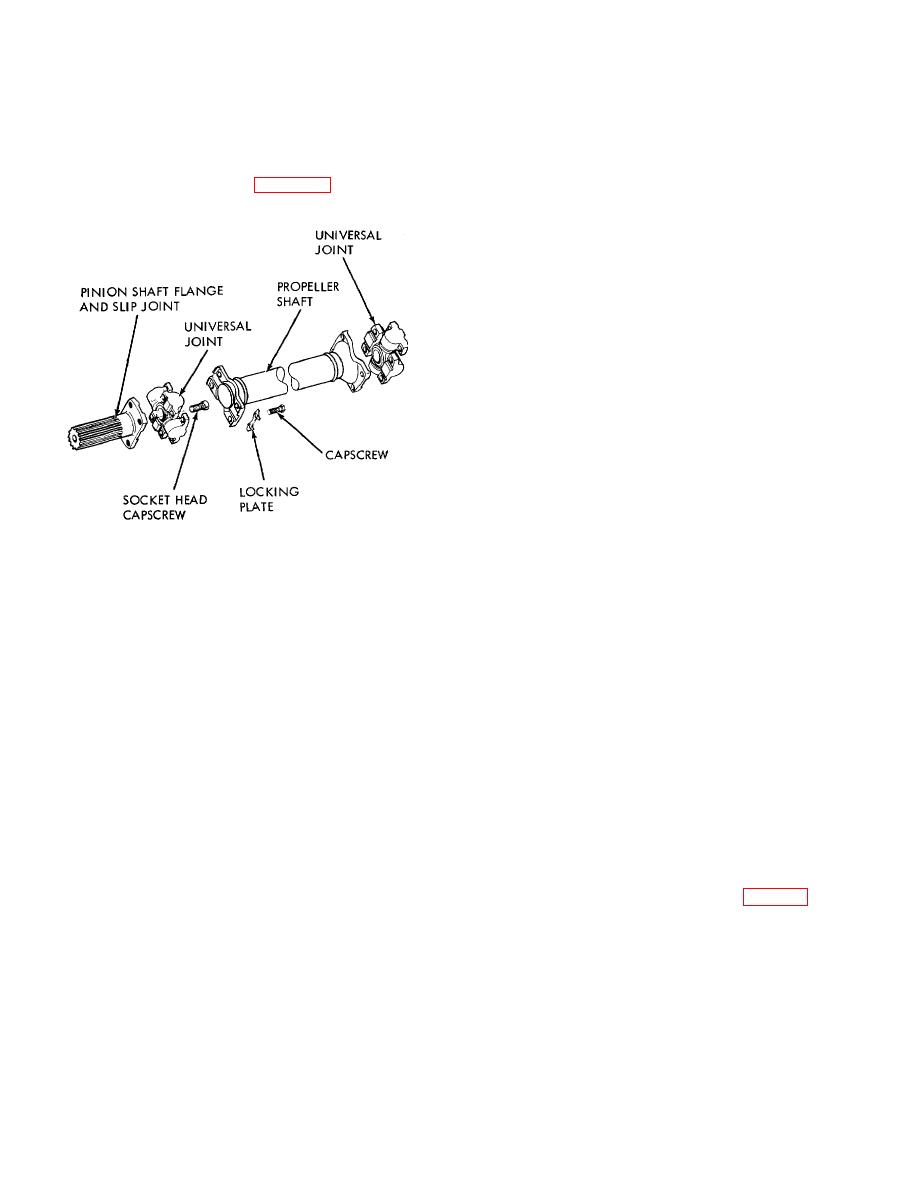

(1) Remove wires and socket head

capscrews holding universal joints to the pinion shaft

propeller shaft assembly should be cleaned

flange and slip joint. Refer to figure 4-45.

thoroughly before assembly. Abrasives are very

harmful to this assembly.

(1) After the universal joints have been

removed from the truck, break connecting plate tying

the trunnion bearings together. These connecting plates

need not be replaced.

(2) Inspect all bearings and surfaces for

irregularities and replace damaged parts.

(3) Pack the trunnion bearings thoroughly

with a high melting point wheel bearing or universal joint

grease.

Make sure grease fully covers bearing

surfaces.

(4) To reassemble, reverse the removal

procedure. It is recommended that the capscrew locking

plates be replaced.

c. Installation. To install the drive shaft, reverse

the removal procedure.

4-47. Drive Axle Assembly

The drive axle and bearings should be

ME 3930-624-12/4-45

lubricated at periodic intervals in accordance with the

current lubrication order. All parts should be checked

Figure 4-45. Universal joint and propeller shaft.

for possible damage and excessive wear.

(2) Slide the output shaft slip joint into the

4-48. Differential

transmission and remove the propeller shaft assembly.

The oil level in the differential housing should

(3) Bend back clips on a capscrew locking

be checked periodically and changed as specified in the

plates and remove both universal joints.

current lubrication order.

(4) If necessary remove slip joint from

transmission.

Section XIV. MAINTENANCE OF THE BRAKES

of the drive axle, and the shoe assemblies are mounted

4-49. General

on the backing plate.

The parking brake is a dual shoe mechanical

brake, mounted on the drive shaft, and can be used

either as a parking brake or an emergency brake. The

4-50. Parking Brake

brake shoes are actuated through a cable by an

a. Removal.

adjustable over-center type lever mounted on the left

(1) Remove the floor plate.

hand cowl panel. A service brake is mounted on each

(2) Remove the clevis pin from the yoke and

of the drive wheels. The service brakes are operated by

remove the yoke from the brake lever (fig. 4-46).

hydraulic pressure. The brake drum rotates on the end

4-40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |