|

|||

|

|

|||

|

Page Title:

TABLE 6-1. TRANSMISSION PRESSURES |

|

||

| ||||||||||

|

|

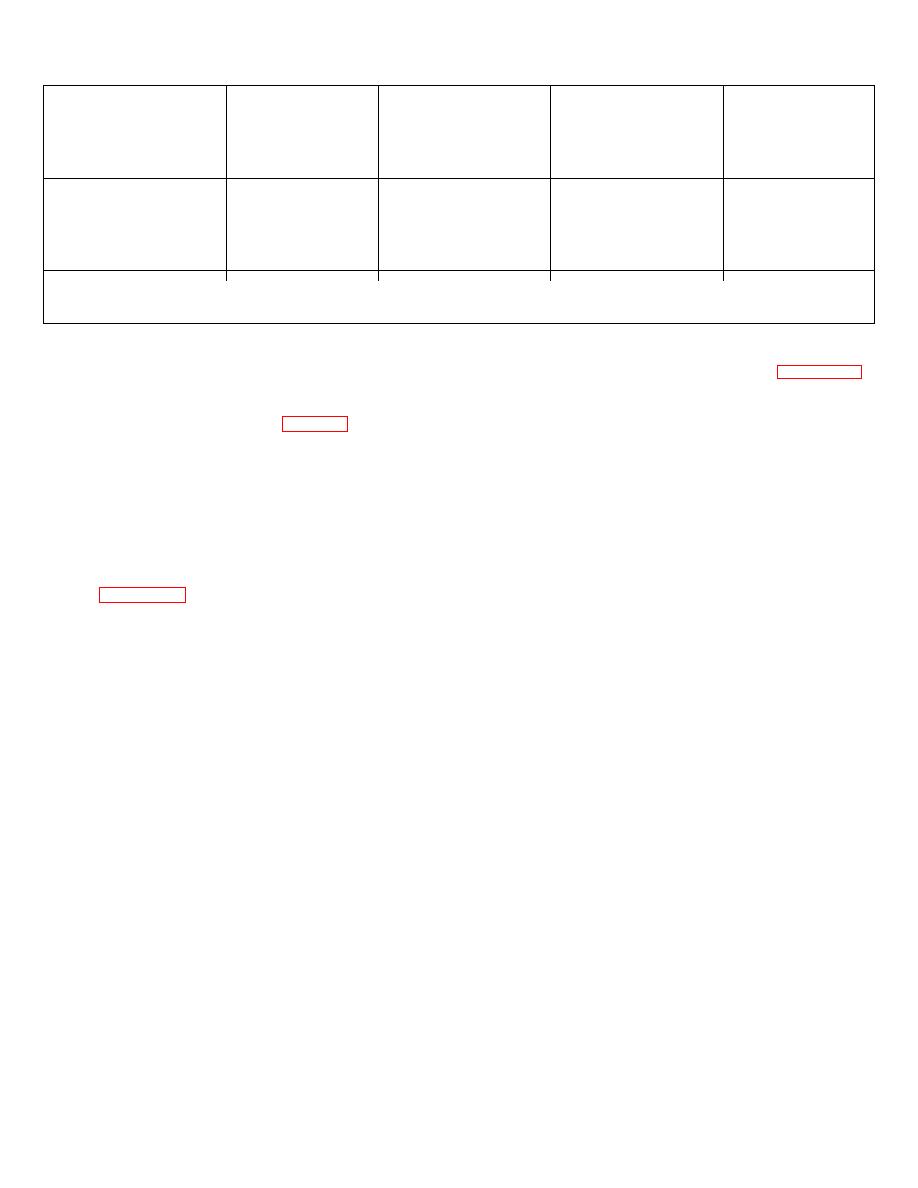

TABLE 6-1. TRANSMISSION PRESSURES

Converter

Engine

Main line

charging

Forward

Reverse

RPM

pressure

pressure

clutch

clutch

Min. Max.

Min.

Max.

Min. Max.

Min. Max.

500

20

30

15

25

15

25

15

25

1000

58

68

42

50

50

58

50

58

1500

110

120

74

84

77

87

77

87

2000

120

135

84

101

80

93

80.

93

Idle rpm for this vehicle is 450 to 500 maximum. Maximum rpm is 2400 and stall rpm is 1615 to 1785 at 200 deg. oil

temperature.

(4) With inching valve out (brake pedal

e. Transmission disassembly.

depressed), both FORWARD CLUTCH PRESSURE and

REVERSE CLUTCH PRESSURE must be 0 psi at all

(1) Remove capscrews (23 and 24, figure 6-16)

engine speeds.

and washers (5) from valve (22) body block and remove

valve from transmission.

(5) Test pressures listed in table 6-1 at all engine

speeds listed.

(2) Mark oil pump (78) and case front half (73) to

insure proper reinstallation, and remove capscrews (80)

d. Removal.

and washers (79) holding pump to case front half.

(1) Drain oil from transmission. Disconnect

(3) Lay transmission on case rear half (45) and

leads at neutral safety switch and at transmission

remove capscrews (71 and 72), and washers (70)

warning light transmitter.

holding case front half (73) to case. Lift off case front

half and clutch assembly (2) as a unit.

(2) Disconnect oil cooler hoses at cooler bypass

valve (figure 6-15) and cooler return port. Cap hoses

NOTE

and plug ports to exclude dirt.

Be careful not to damage the seal

rings (3) in the collector ring (6).

(3) Disconnect inching and shifting linkage at

control valve.

(4) Remove case front half from clutch assembly

by removing retaining ring (75) on the turbine shaft and

(4) Place wheeled floor jack or equivalent

sliding case front half from clutch assembly.

beneath transmission to relieve weight, and remove nuts,

screws and washers from rubber sandwich mountings.

(5) Remove the forward gear (25) and forward

Remove mountings.

shaft (27) in the following manner:

(5) Remove twelve screws and washers which

(6) Remove capscrews (34) and lockwashers

attach transmission to engine.

(33) holding forward shaft cover (32) and remove cover

and gasket (31).

WARNING

(7) Remove retaining ring (26) on the forward

At this point, the transmission is

side of the forward gear.

supported only by the floor jack

(8) Tap the forward shaft on the front end, while

mentioned.

Take all necessary

holding the forward gear through the valve block opening

precautions that it does not fall, to

and pull the shaft (27) and bearing (28) assembly

cause injury to personnel or damage

rearward from the gear box.

to equipment.

(6) Draw transmission horizontally from engine

until splined shafts leave bore of torque converter on

engine flywheel, raise truck as needed to give clearance,

and remove transmission from under truck.

73

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |