|

|||

|

|

|||

|

Page Title:

Wheel cylinder disassembly and inspection. |

|

||

| ||||||||||

|

|

(1) Fill master cylinder with specified brake fluid.

CAUTION

Do not use cutting pliers to grasp springs

(2) Remove screw in bleeder fitting and slip piece of

for removal. Any resulting nicks make

small hose about 18 inches long over end of fitting.

spring subject to failure.

(3) With a second man applying pressure to pedal,

(3) Hold pin from rear of backing plate, press outer

crack open bleeder fitting to permit fluid to escape

antirattle. spring retainer in to compress spring, and

through hose into container of brake fluid. Look for

rotate it a quarter turn, to release it. Take off pin, spring

bubbles in escaping fluid.

and retainers, and remove brakeshoes.

(4) Continue pumping fluid until discharged fluid is

(4) Disconnect brake line, remove elbow, adapter

clear and free of bubbles, meanwhile maintaining level of

and washer from wheel cylinder. Disconnect bleeder line

fluid in master cylinder reservoir. Repeat at other wheel

at cylinder. Remove two capscrews and lockwashers

if both brakes were serviced.

and lift off wheel cylinder.

g.

Adjustment.

Brake lining-to-drum operating

b. Wheel cylinder disassembly and inspection.

clearance is automatically adjusted with each application

of the brakes. There is no need to adjust the brakes

(1) Remove boots and push out cups, pistons and

manually.

spring from wheel cylinder. Discard boots and cups.

6-23. MASTER CYLINDER.

(2) Inspect cylinder bore for rust pits or scoring.

Discard cylinders which cannot be cleaned up with light

a. Removal.

honing.

(1) Unscrew bolt, fitting and stoplight switch from

c. Wheel cylinder reassembly. Wet internal parts in

master cylinder. Do not disassemble this group of parts.

specified hydraulic brake fluid, and reverse b. (1) above.

(2) Remove cotter pin (Figure 6-7) and clevis pin

d. Brakeshoe. Inspect brakeshoe lining and replace

from push rod yoke, remove two nuts and washers,

shoe and lining assembly as required. I e. Installation.

through bolts, and master cylinder.

Turn cam bolts so brakeshoes will be held at furthest in

position, and reverse a. above.

b. Repair.

f. Brake bleeding. After assembly, bleed air from

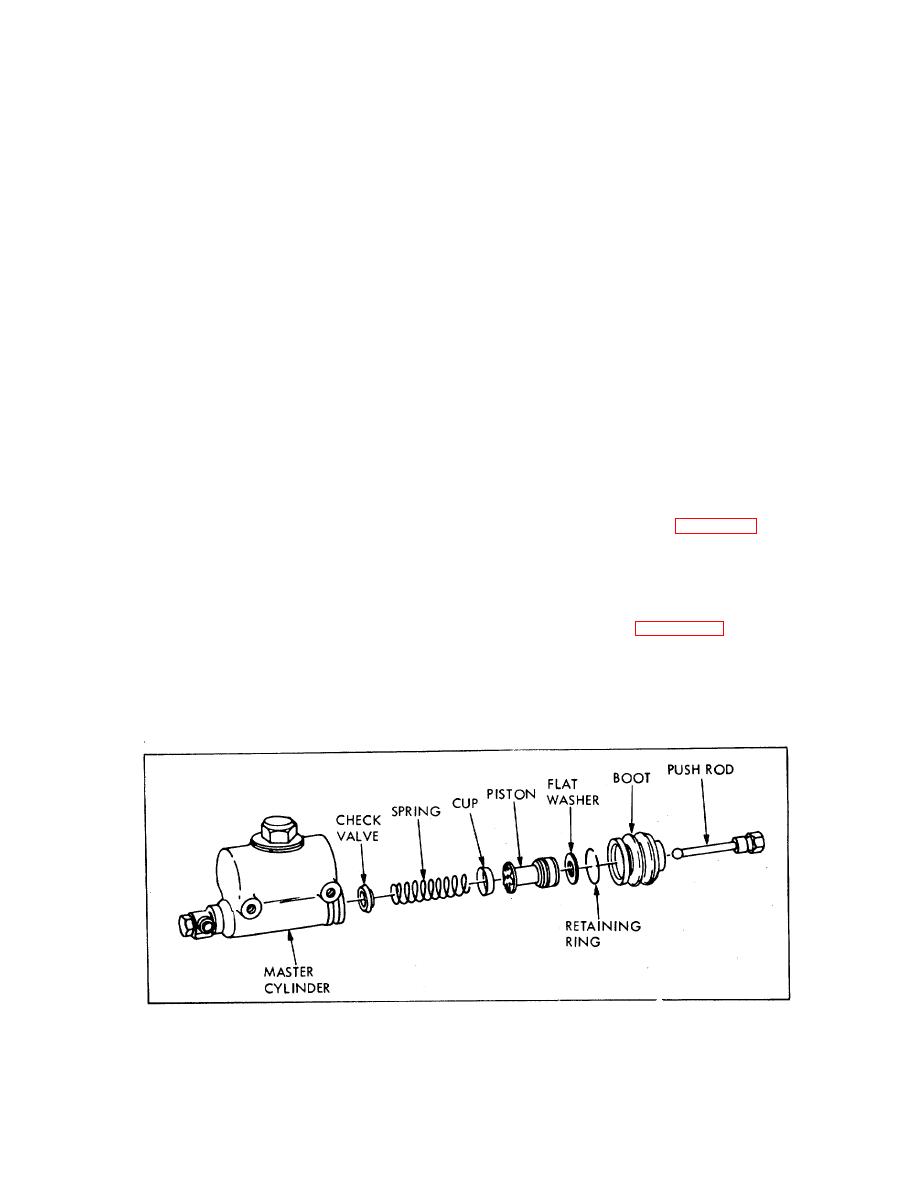

(1) Remove boot (Figure 6-10) and push rod, take

system

at

bleeder

fitting

as

follows:

out retaining ring, and remove washer, piston, cup,

spring and check valve.

Figure 6-10. Master Cylinder, Exploded View

62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |