|

|||

|

|

|||

|

Page Title:

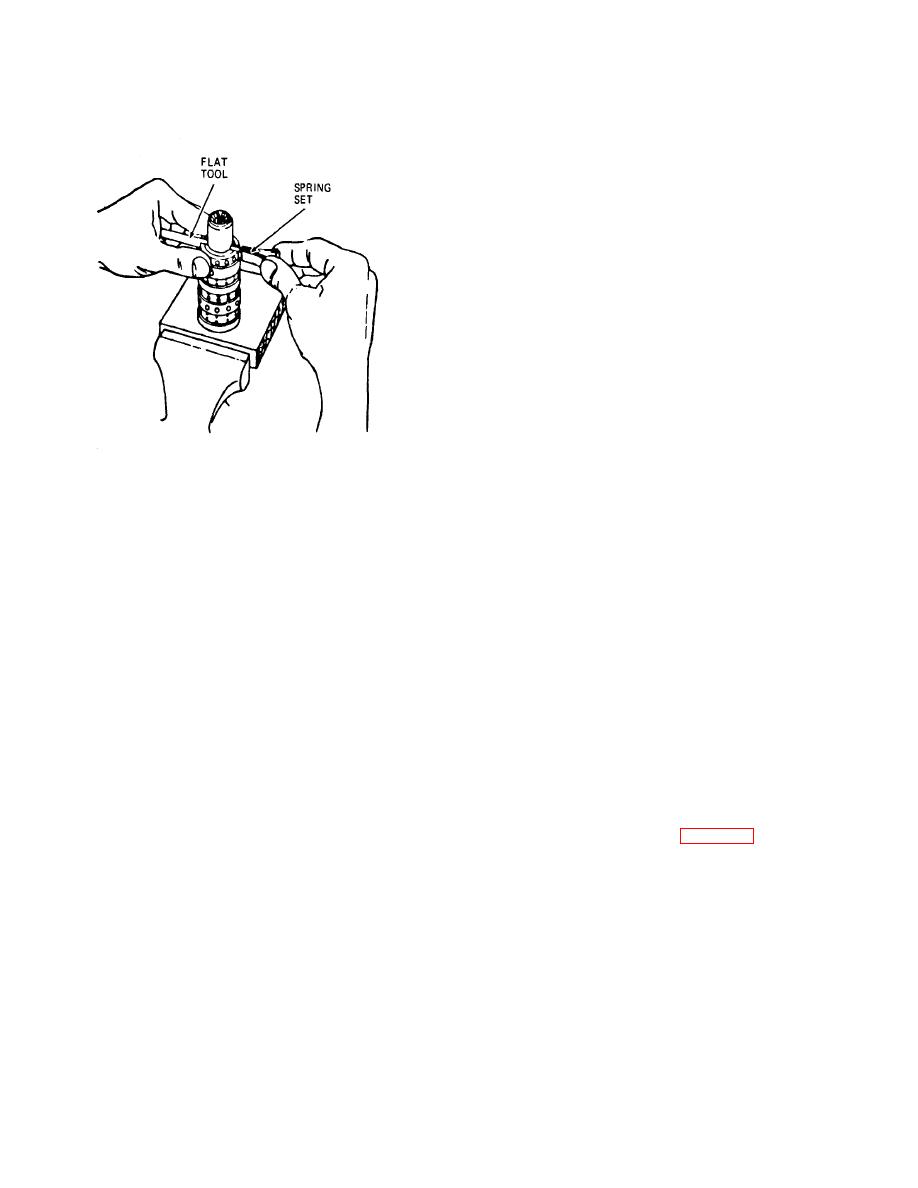

Figure 9-4. Install centering spring set. |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

Caution: Do not pull control assembly

beyond flush position or cross pin (41) will drop into

housing discharge groove.

(16) Turn splined end of control assembly (38),

checking for free rotation.

(17) Install new packing (43) and check plug (44)

in check plug hole. Use steady pressure on plug and

rock it slightly so packing feeds in smoothly without

cutting.

(18) Install new packing (40) and seal (24) on

spool (50).

(19) Seat cap locator bushing (39), large outside

diameter up, against spool (50) evenly.

c. Mounting Plate.

(1) Check mounting plate seal grooves for

cleanliness and smooth condition.

(2) Install and smooth down new quad ring shaft

seal (24) and oil seal (16) into mounting plate (17) seal

grooves.

Note: Oil seal (16) lip must face away from unit.

(3) Place the mounting plate subassembly) over

ME 3930-621-35194

the spool shaft and slide it down smoothly in place over

the cap locator bushing (39) so that seals will not be

Figure 9-4. Install centering spring set.

damaged.

(4) Aline the bolt holes in the cover (17) with the

(12) Center spring set (42), alining each spring

tapped holes in the housing (48). Be sure the mounting

so the entire set is flush with upper surface of control

plate rests fairly flush against end of housing assembly

spool and sleeve.

so that the cap locator bushing is not cocked.

(13) Install the cross pin (41) through the spool

(5) Install mounting plate attaching bolts (18) and

and sleeve and push into place until pin is flush or slightly

torque each to 150 inch-pounds. d. End Plate.

below the sleeve diameter at both ends.

(1) Reposition control housing (48) in vise,

(14) Place the housing (48) on a solid surface

clamping the mounting plate with 14-hole surface up.

with the port face down. Install the spool assembly with

(2) Check that control spool and sleeve are flush

the splined end of the spool (50) entering the 14-hole

or slightly below 14-hole surface and that surface is

end of the housing first. Push parts gently into place with

clean.

a slight rotating motion.

(3) Place end plate (22) over control spool and

Caution: Use extreme care so control

sleeve, alining bolt holes in plate with tapped holes in

assembly (38) does not lose alinement when

housing (48).

entering housing (48).

(4) Place rotor ring (21) on assembly and aline

(15) Install control assembly (38) in housing bore until

bolt holes.

flush with 14-hole end of housing.

(5) Place splined end of drive (23) in rotor gear

star so slot at control end of drive is alined with outside

diameter valleys of gear. See figure 9-5.

9-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |