|

|||

|

|

|||

|

Page Title:

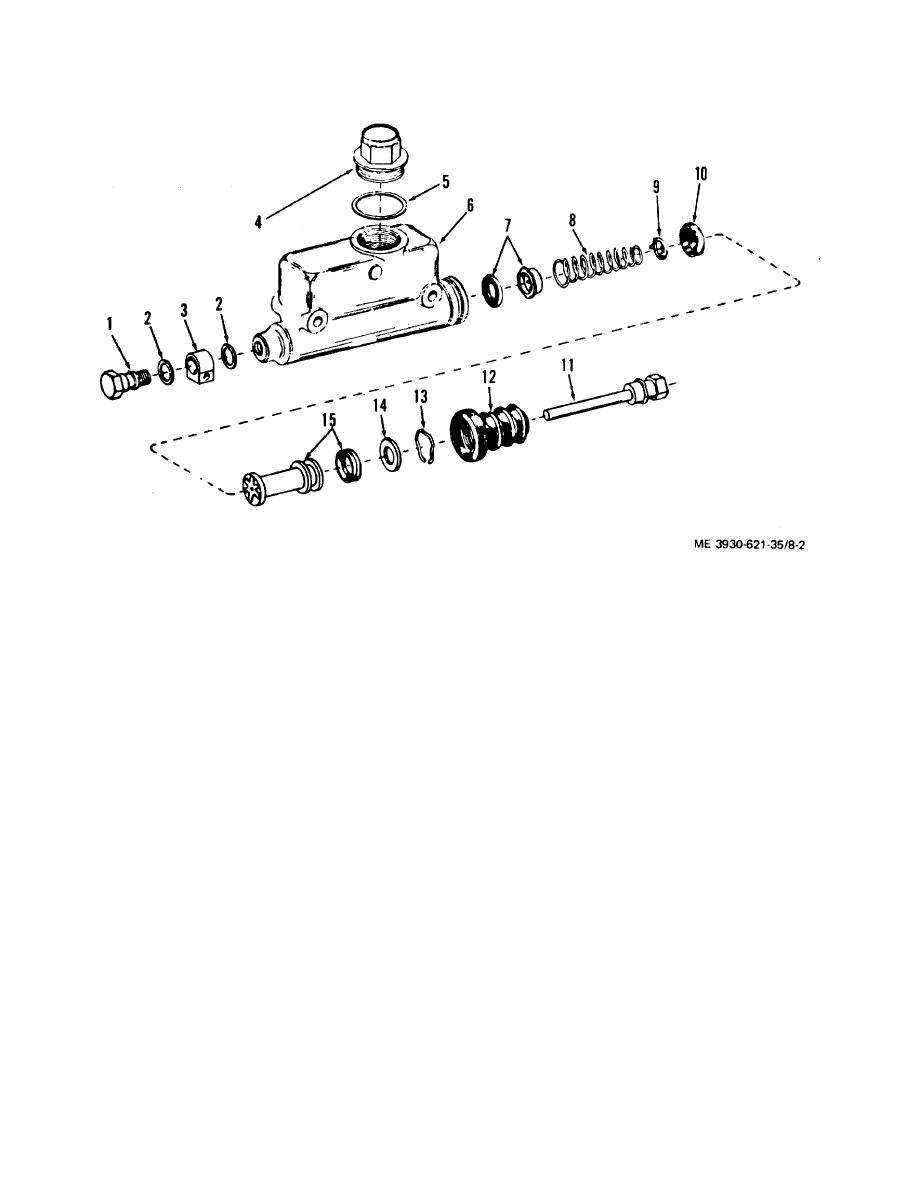

Figure 8-2. Master brake cylinder exploded view |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

Figure 8-2. Master brake cylinder exploded view

1.

Outlet bolt

9. Retainer

2.

Gasket

10. Piston cup

3.

Fitting

11. Piston rod

4.

Plug

12. Boot

5.

Gasket

13. Lockwire

6.

Cylinder and tank

14. Stop plate

7.

Check valve

15. Piston assembly

8.

Spring

d. Cleaning and Inspection.

(3) Make sure intake and by-pass ports are

(1) Clean all parts with denatured alcohol or

open. By-pass ports may be probed with soft iron wire.

brake fluid, and keep clean in all following operations.

(4) If it is necessary to resurface the cylinder wall, use

the following procedure:

Warning: Dirty parts or internal rubber

(a) Coat walls of cylinder bore with hydraulic brake

parts which become swollen, tacky, and otherwise

fluid.

deteriorated by mineral base cleaning solvents can

(b) Secure master cylinder body in a bench vise.

lead to brake failure and possible injury to the

(c) Using honing equipment, remove material from

operator.

cylinder bore in single passes.

(2) Inspect cylinder bore.

Deep blemishes

(d) After each pass is completed, remove hone and

require boring to resurface the cylinder wall. Do not bore

inspect for scratches and pitting. Remove only enough

beyond manufacturer's specifications. Pressure marks

material to recondition cylinder bore. Do not hone

may be polished out with crocus cloth.

cylinder oversize.

Caution: Do not use emery cloth or sand pa

Note. If the master cylinder has been honed

per.

oversize or greater than 1.007 of an inch it must be

replaced.

8-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |