|

|||

|

|

|||

|

Page Title:

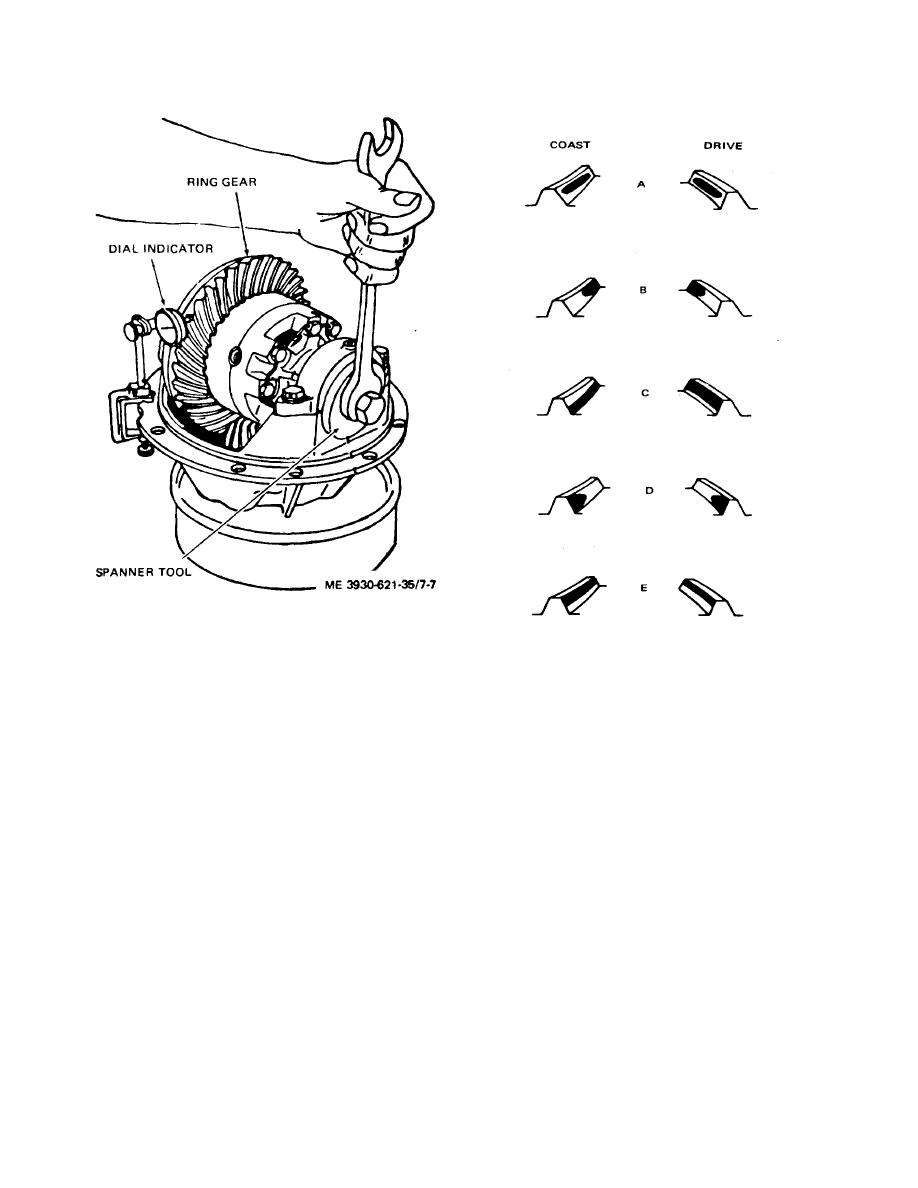

Figure 7-7. Adjusting backlash line. |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

A - CORRECT ADJUSTMENT.

Figure 7-7. Adjusting backlash line.

B - HEAVY CONTACT ON TOE OF TOOTH. TO COR-

RECT MOVE RING GEAR AWAY FROM PINION.

(c) Coat entire ring gear with Prussian Blue or white

MOVE PINION TOWARDS RING GEAR TO AGAIN

lead.

SECURE CORRECT BACKLASH.

(d) Rotate ring gear (2) several times, holding back

C -- BEARING TOO LOW. HEAVY CONTACT ON

on pinion to create load effect.

FLANK OF TOOTH. TO CORRECT THIS MOVE

(e) Inspect teeth of pinion and compare with figure 7-

PINION AWAY FROM RING GEAR UNTIL

8. Tooth bearing should start I / 32 to 1/ 16 of an inch

CONTACT COMES TO FULL WORKING DEPTH

from the top of the tooth and continue down to an

OF GEAR TOOTH WITHOUT BREAKING

equivalent distance from the bottom of the tooth.

CONTACT AT FLANK.

MOVE RING GEAR

Note. Do not be concerned about the amount of

TOWARDS PINION TO SECURE PROPER

paint removed. This will vary with load applied.

BACKLASH.

D -HEAVY CONTACT AT HEEL OF TOOTH. TO

CORRECT MOVE RING GEAR TOWARDS

PINION. MOVE PINION AWAY FROM GEAR TO

OBTAIN CORRECT BACKLASH.

E - SHOWS HEAVY CONTACT ON TOOTH FACE.

MOVE PINI ON TOWARDS GEAR UNTIL

CONTACT COVERS FLANK OF TOOTH WITHOUT

BREAK- ING CONTACT AT FACE. MOVE GEAR

AWAY FROM PINION TO SECURE CORRECT

BACKLASH.

Figure 7-8. Differential gear tooth patterns.

7-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |