|

|||

|

|

|||

|

Page Title:

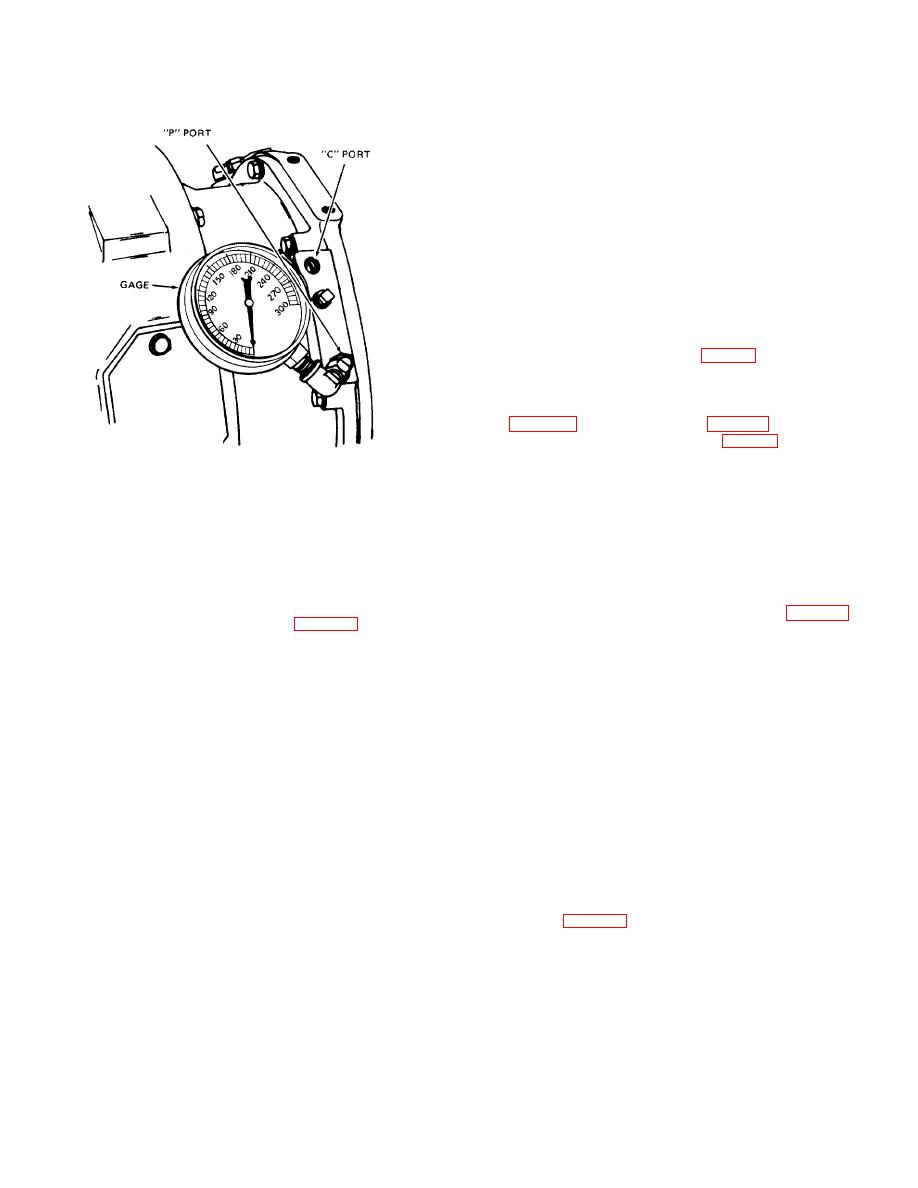

Figure 6-8. Checking pump and converter pressure. |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

(1) Install a pressure gage in front on top of control

salve.

(2) Check clutch pressure in forward direction as

follows:

(a) Position truck against wall and apply parking

and foot brake. Drive wheels must be locked.

(b) Accelerate engine momentarily to wide open

throttle and note pressure indication on gage.

(c) If gage reading is not below 65 psi. or does

not go above normal pump pressure, the pressure in the

forward circuit is normal. Pressure should never be

below 65 psi.

(d) If pressure is above normal pump pressure,

check for incorrect or faulty regulator spring (20, fig. 6-

11) tension, inoperative inching valve, or a restricted

orifice in the forward cylinder (3, fig. 6-7 ).

(e)If pressure is below 65 psi, check for low oil

level, restricted lines or passages, damaged collector

rings, faulty or incorrectly adjusted selector valve spool

(9, fig. 6-11), faulty pump 16, fig. 6-3), or excessive

leaks in the transmission drum (22, fig. 6-7).

(3) Check clutch pressure in reverse direction as

follows:

Figure 6-8. Checking pump and converter pressure.

(a) Install pressure gage in rear port on top of

control valve.

(3) Accelerate to full governed speed and note

(b) Idle engine and engage clutch in reverse

gage pressure.

direction.

(4) If pressure is 65 to 80 psi, converter is in

(c) If gage reading is 25+21/2 psi, the pressure in

normal operating condition.

the reverse circuit is normal.

(5) If pressure is above 80 psi, when engine is

(d) If pressure reading is not within tolerance,

accelerated, check the following:

adjust regulator valve and replace spring (20, fig. 6-11) if

(a) Exessive pump pressure (para 6-2 b (5).

necessary.

(b) Enlarged metering orifices.

e. Clutch-Pressure at Free Running.

(c) Restricted converter return passages.

(1) Raise both drive wheels off floor and block

(6) If pressure is below 65 psi, when engine is

securely. Both wheels must be free to rotate.

accelerated, check the following:

(2) Install pressure gage in front port on top of

(a) Low oil level

control valve.

(b) Restricted oil strainer

(3) Hold inching pedal up so inching valve plunger

(c) Faulty pump

cannot move.

(d) Clogged converter orifice in pump collector

(4) Run engine at full governed speed forward and

ring

check pressures. If pressure is below 65 psi or above

(e) Faulty cooler by-pass valve.

normal pump pressure, inspect in accordance with d

(7) Bring engine to idling speed.

above.

(8) If pressure is 40 to 60 psi, converter is in

(5) Install pressure gage in rear port on top of

normal operating condition.

control valve.

d.

Clutch

Pressure

at

Stall.

(6) With transmission in reverse, idle engine and

check pressure. If reading is not within 25t21/2 psi,

adjust oil cooler pressure regulator valve and replace

spring (20, fig. 6-11), if necessary.

6-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |