|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

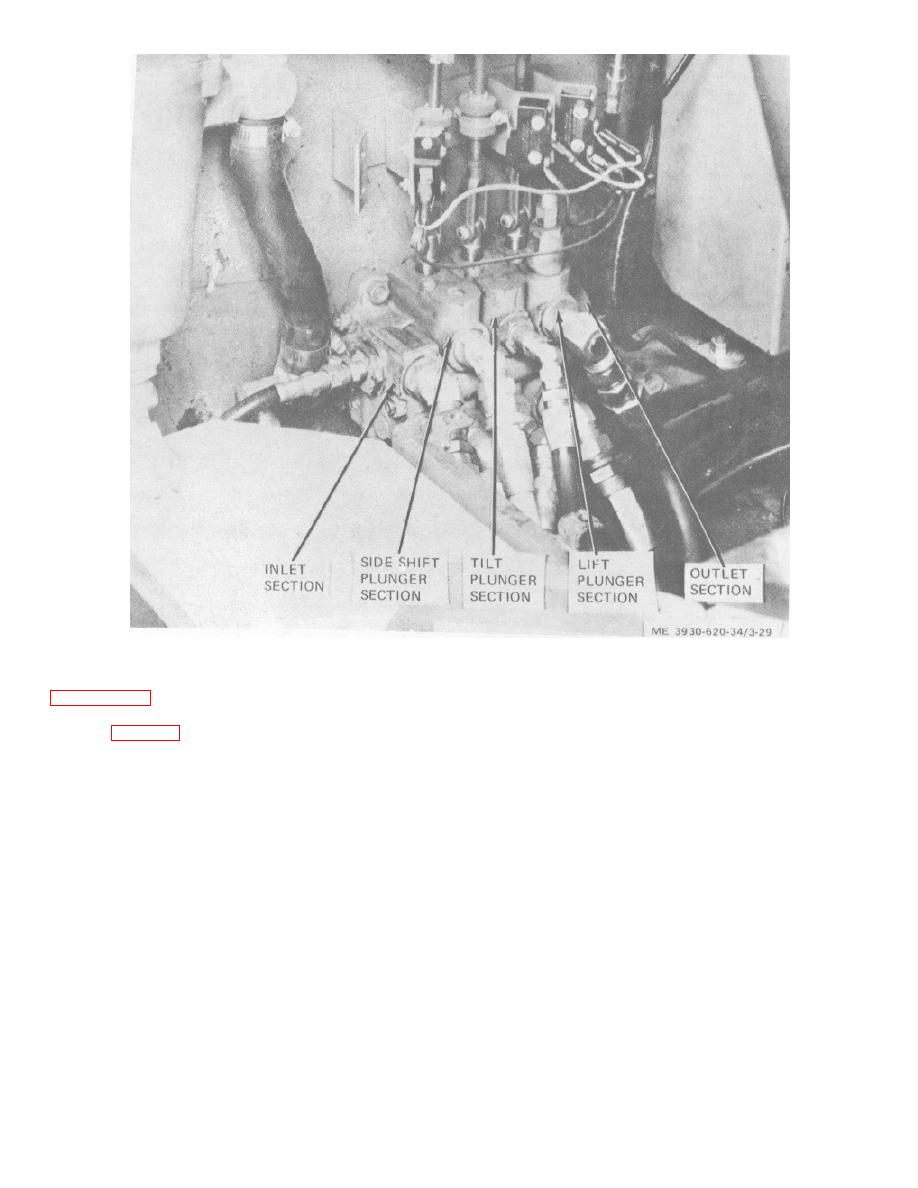

Figure 3-29. Control valve.

b. Removal. Remove control valve according to

facing downward and tap lightly on plunger section until

poppet slides out.

c. Disassembly. Disassemble control valve as

(7) Remove lift plunger section from tie rods.

(8) Remove seal plate (56) from plunger end

follows: (fig. 3-30.)

of section.

Caution:

Disassembly of hydraulic

(9) Remove plunger cap (51) and seal plate

system components shall be performed in a clean

(56) at opposite end of housing and pull lift plunger from

working area, free of dirt and other foreign matter.

housing.

Note. Position all parts on a flat working

(10) Remove wiper (57) and preformed

surface in order of disassembly, insuring that parts,

packing (58) from lift plunger end of section and identify

which are common between sections, do not become

from which end these were removed.

mixed. Identify and tag all parts.

(11) Remove special screw (54), plunger

(1) Insure that working area is clean and free

spring (55), spring seats (53), and wiper (57) from lift

of dirt and other foreign matter.

plunger.

(2) Position control valve on inlet end.

(12) Remove acorn nut (76), jamnut (75), and

(3) Remove retaining nuts from tie rods (82

copper washers (77) from relief assembly.

and 84).

(13) Turn relief valve assembly out of inlet

(4) Remove outlet section (81) from tie rods.

housing. Flats are provided on cap to remove relief

(5) Remove spring (80), poppet (79), and

valve assembly.

preformed packing (78) from lift plunger section.

(6) If poppet cannot be removed easily, hold

lift plunger section above working surface with poppet

3-46

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |