|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

CAUTION

slightly. Any time a new flywheel is

It is extremely important that all burs

installed. be certain to check the

and nicks be removed from mating

timing marks of the old and new

surfaces of flywheel and crankshaft

flywheels.

(3) To install a new ring gear -

flange. If surfaces are not smooth

(a) Heat ring gear to approximately 400

and true, the flywheel may wobble.

degrees Fahrenheit (400F.). The desired temperature

Flywheel wobble would result in im-

proper torque converter operation,

produces a dull red heat visible in the dark.

(b) Place heated ring gear on flywheel

engine vibration, and shortening of

with chamfered ends of gear teeth away from flywheel

the life of crankshaft bearings and

shoulder, and toward the oil seal flange. The flywheel

other parts.

should be at room temperature.

(4) Inspect flywheel housing for cracks,

(c) Drive ring gear down tight against

bends, nicks, holes, stripped threads, corrosion, and

shoulder of flywheel.

other damage which would interfere with its proper

(d) After the installation of housing,

operation.

flywheel, and ring gear, and before installation of starting

(5) Replace defective parts as authorized.

motor and transmission, dial indicate both flywheel and

c. Installation.

housing as follows:

(1) Install flywheel and housing by reversing

1. Attach a dial indicator to housing, at

procedures in a above.

one of the transmission mounting holes, and check

(2) Install new inner and outer oil seals

flywheel for runout. Runout should not exceed 0.005

whenever any signs of leakage appear, and whenever

inch.

engine is overhauled.

2. Attach dial indicator to center of

NOTE

flywheel, and check flywheel housing for runout, which

Flywheel can be installed in only one

should never exceed 0.010 inch.

position on the crankshaft flange

because on of the capscrews is offset

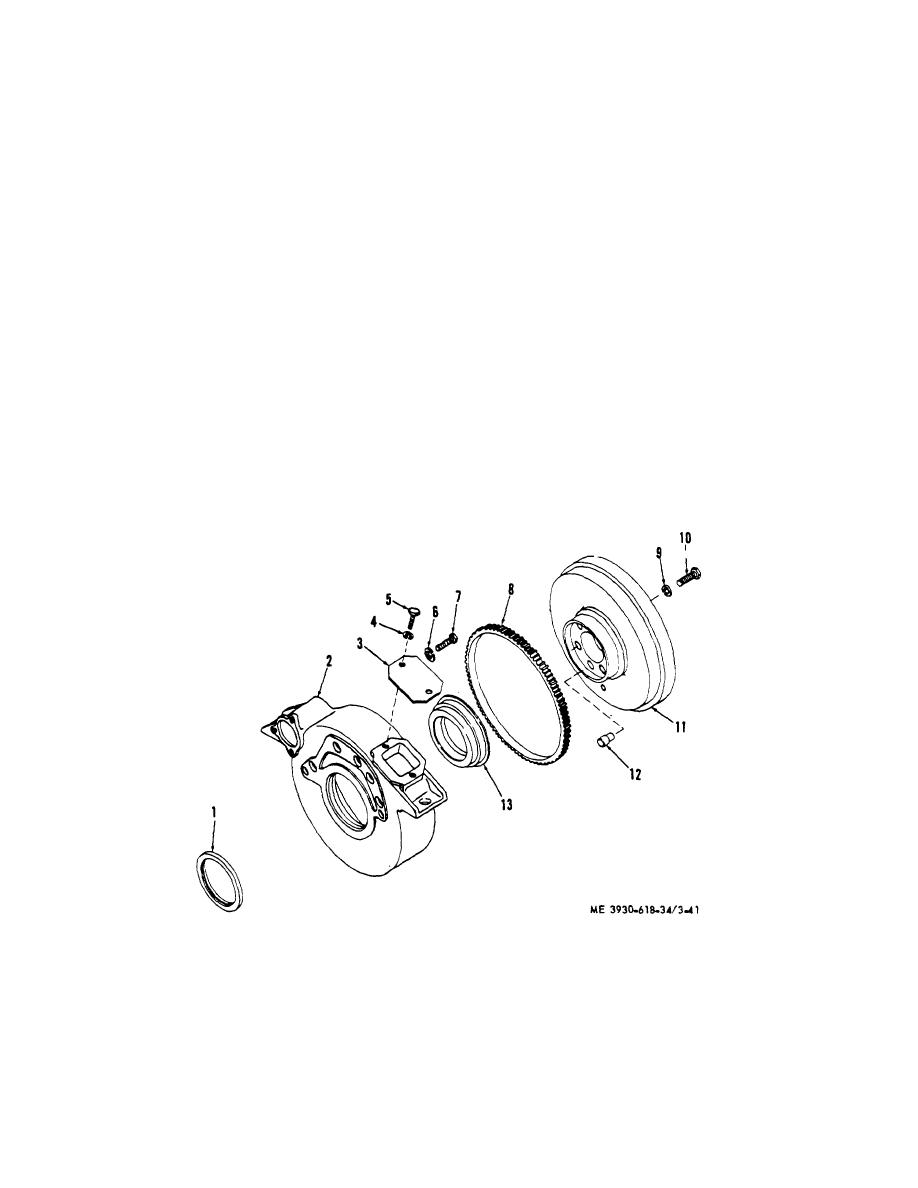

1 Outer oil seal

8 Ring gear

2 Housing

9 Lockwasher

3 Cover

10 Capscrew

4 Lockwasher

11 Flywheel

5 Capscrew

12 Dowel

6 Lockwasher

13 Inner oil seal

7 Capscrew

Figure 3-41. Flywheel, ring gear, and housing.

3-52

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |