|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

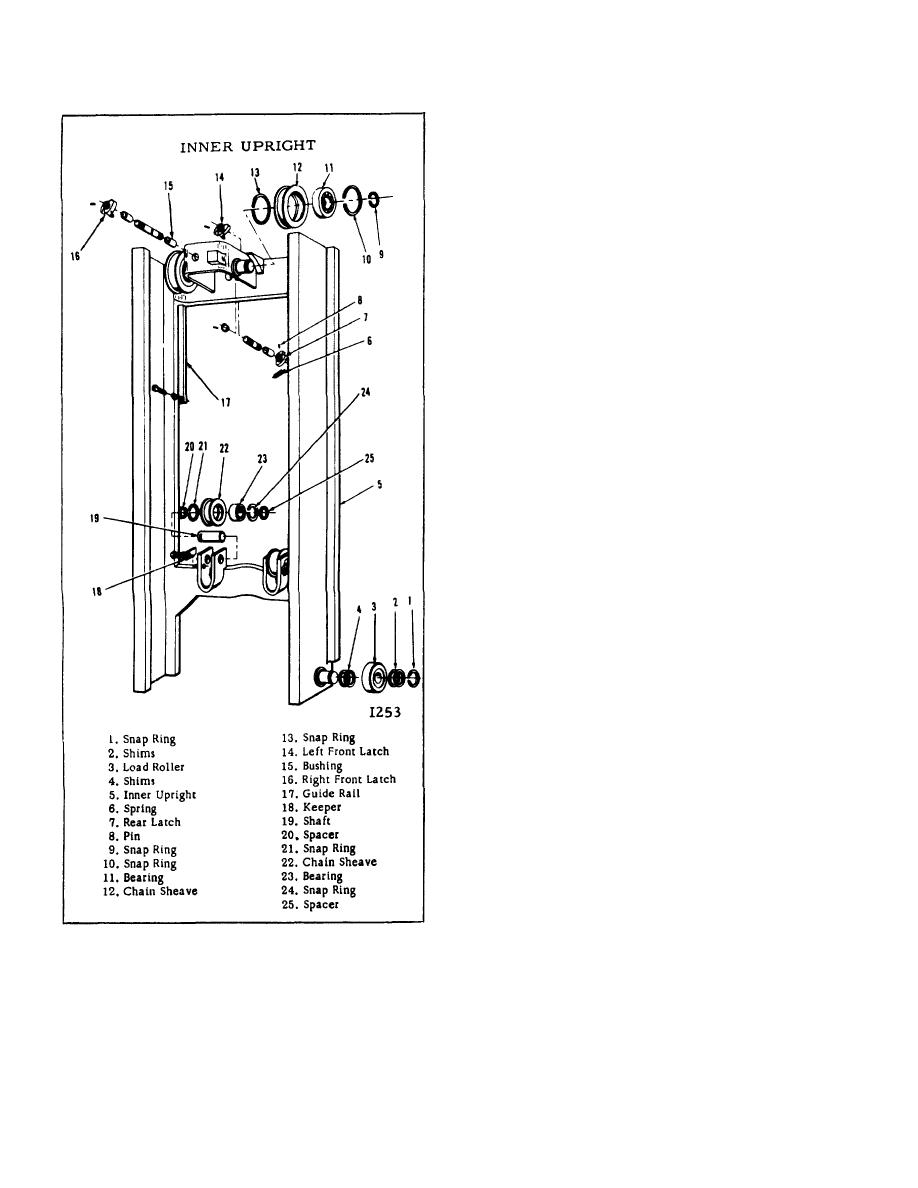

UPRIGHTS

Six chain sheaves provide the necessary rolling

surfaces for the two load chains. The sheaves are ball

bearing equipped and located in the following places:

Two in back of an intermediate crossmember of the

inner upright; one on each side of the crosshead; one on

each side of a box at the top of the inner upright. The

box is welded on the front of the upper crossmember.

The bearings are shielded, lubricated for the life of the

bearing, and replaceable.

One end of each load chain is attached to the back of

the carriage and the other end is attached to a chain

anchor. The bottom ends of the chain anchors are

attached to the cylinder base. Provision for chain

adjustment is at this point.

The bottom crossmember of the outer upright supports

the cylinder. Bolted on top of the support is a shim-

adjusted pad. The pad supports the inner upright when

it is completely lowered. Shims are used to adjust the

relationship between the inner and outer uprights.

A sliding surface between the inner and outer uprights is

provided by strip bearings between the two outer

channels of each of the two assemblies. The strip

bearings are shim adjusted and attached to the top of

the outer upright.

Of the latches, two are behind the upper crossmember

of the inner upright and one is on the front of the box.

Looking from the driver's seat, the right rear latch and

the front latch are splined and pinned to a common

shaft.

Welded to the front of the box is a block and bolted to

the back of the upper crossmember of the carriage is

another block. These are in line with each other and are

called "lifting blocks". Also screwed into the back of the

same crossmember is a lug.

When the inner upright is completely lowered, the right

rear latch is engaged with the outer upright lug, and

Figure 7.

B-172

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |