|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TRANSMISSION

1. The oil pump may be assembled and installed

by reversing the disassembly and removal procedure.

Lubricate all parts during assembly.

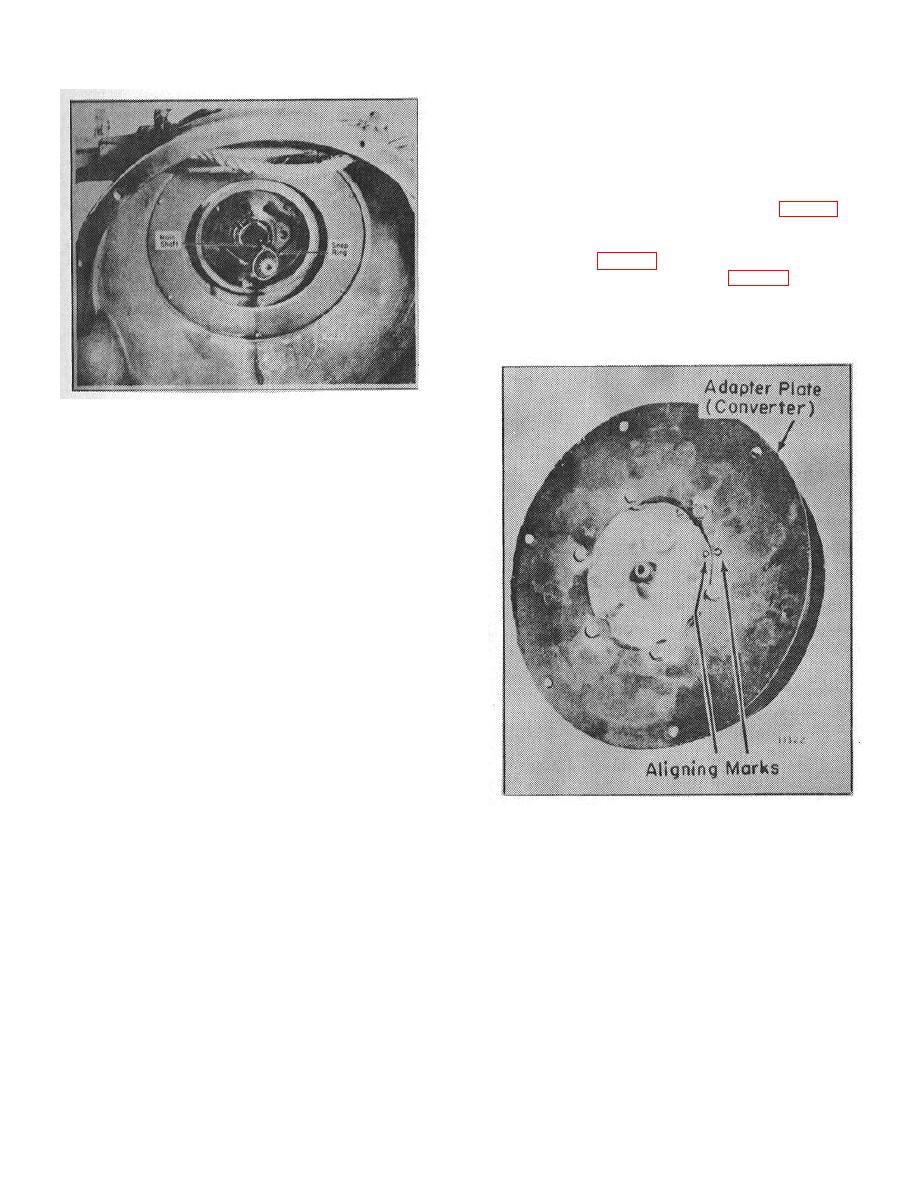

2. Make certain the match mark on the converter

plate lines up with the mark on the flywheel. Bolt the

converter adapter plate to the converter (Fig. 40) an

mount the converter to the engine flywheel, match-

marking the plate and flywheel, whenever a converter is

being installed. (Fig. 36) Using a dial indicator, check

the runout of the impeller hub. (Fig. 41) The total

runout should not exceed .005 inch. If this figure is

exceeded, pry between the converter and the plate and

bend until the correct runout is achieved.

Figure 39.

1. Remove the two flat head machine screws from

the pump assembly.

2. Push the reactor shaft from the pump body.

3. Mark gear relationship with prussian blue.

Remove the gears.

D. CLEANING AND INSPECTION

1. Clean all parts in solvent. Remove all gasket

material from the adapter plate and the pump bore of

the converter housing. Discard all gaskets and O-rings.

2. The mating parts of the pump are ground and

lapped. For this reason, the only items serviced on the

pump are the seals and gasket.

3. Inspect all parts for scratches, wear, burrs, and

nicks. Especially watch for wear of pump gears into the

Figure 40.

pump housing or wear of the driving gear bushing.

Replace the pump if either is worn, or if there is any

3. Remove the converter from the flywheel and

doublt as to the dependability of any other part. l)o not

slide on the drive shaft. Make sure the converter and

try to repair any defective part.

pump tines engage. Mount the entire assembly on the

engine adapter plate and secure. Line up the match

E. ASSEMBLY AND INSTALLATION

marks on the converter plate and flywheel, and secure.

Fill to proper level with specified oil. Remove

B-108

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |