|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ELECTRICAL

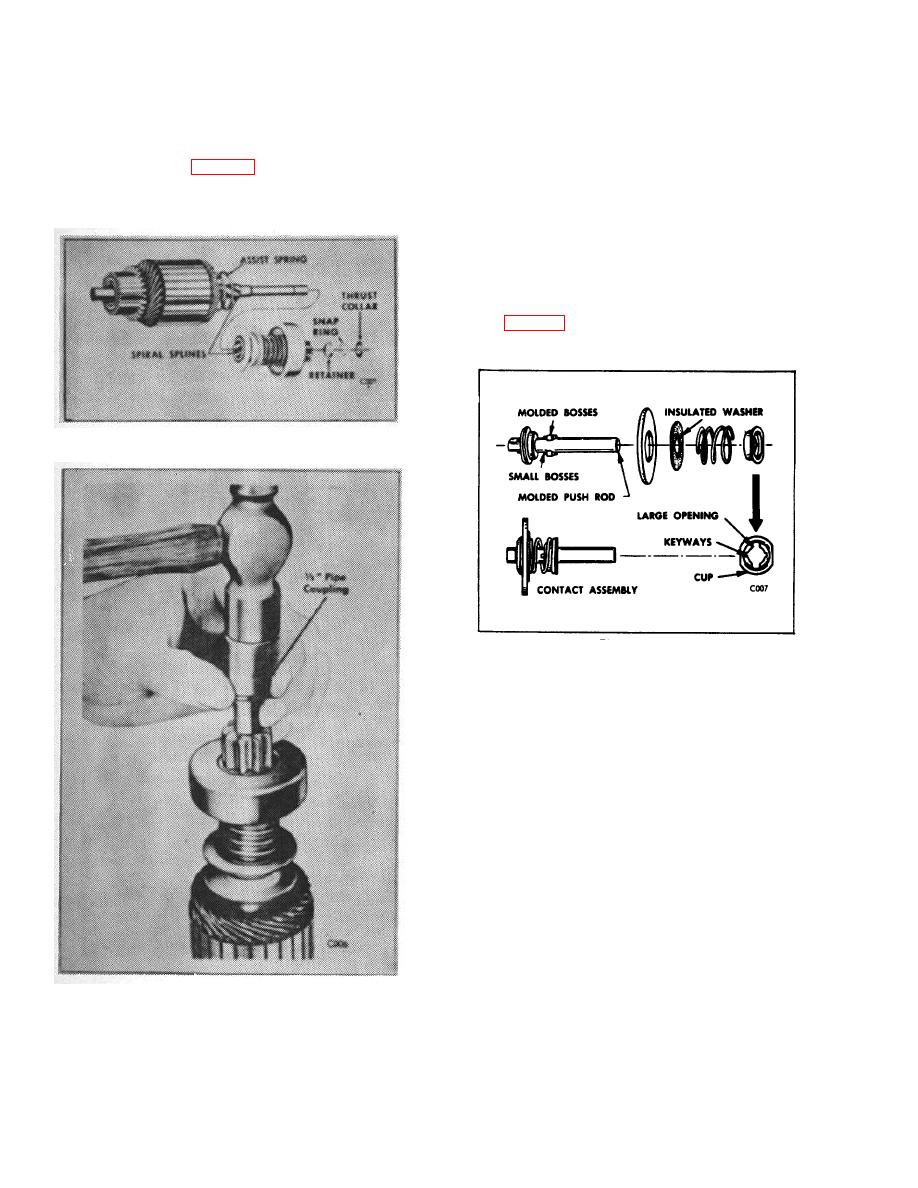

b. Slide a standard 1/2 inch pipe coupling or

c. Remove snap ring from groove in

other metal cylinder of correct size onto shaft

armature shaft. If snap ring is distorted

so end of coupling cylinder butts against edge

during removal, it must be discarded and a

of retainer.

new one obtained for assembly.

hammer to drive retainer down toward arm'

and off snap ring.

d. Slide retainer and over-running clutch

assembly off armature shaft.

7. Remove the solenoid return spring and

plunger. Remove the terminal assembly and the

contact assembly. To disassemble the contact

assembly, push in on the metal cup and rotate 1/4

turn. (Fig. 35) Slide the metal cup, spring, and

washers off the push rod.

Figure 33.

Figure 35.

F. SERVICE PROCEDURES

NOTE: The over-running clutch,

armature, and fields should never

be cleaned in a degreasing tank

or

with

grease

dissolving

solvents, All parts of the motor

except the clutch should be

cleaned with oleum spirits and a

brush. Wipe the clutch with a

clean cloth.

1. Armature

a. Check armature - to - commutator leads

to make sure they are securely

Figure 34.

B-76

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |