|

|||

|

|

|||

|

Page Title:

RECOMMENDED METHOD OF INSTALLING RINGS |

|

||

| ||||||||||

|

|

ENGINE

This must be taken into consideration when checking

alignment of the assembly, since the diameter in line

with the piston pin would be less at the top of the skirt

than at the bottom.

F.

RECOMMENDED METHOD OF INSTALLING

RINGS

1. Grip the connecting rod in a vise with lead lined

jaws. Roll each of the straight side rings in its groove to

be sure there are no burrs or other interference with the

free action of the ring in the groove.

2. Check the ring side clearance at various

positions with a feeler in accordance with the tolerances.

grooves they can be removed and lapped on a flat plate.

Use crocus cloth to narrow them down to the desired

clearance.

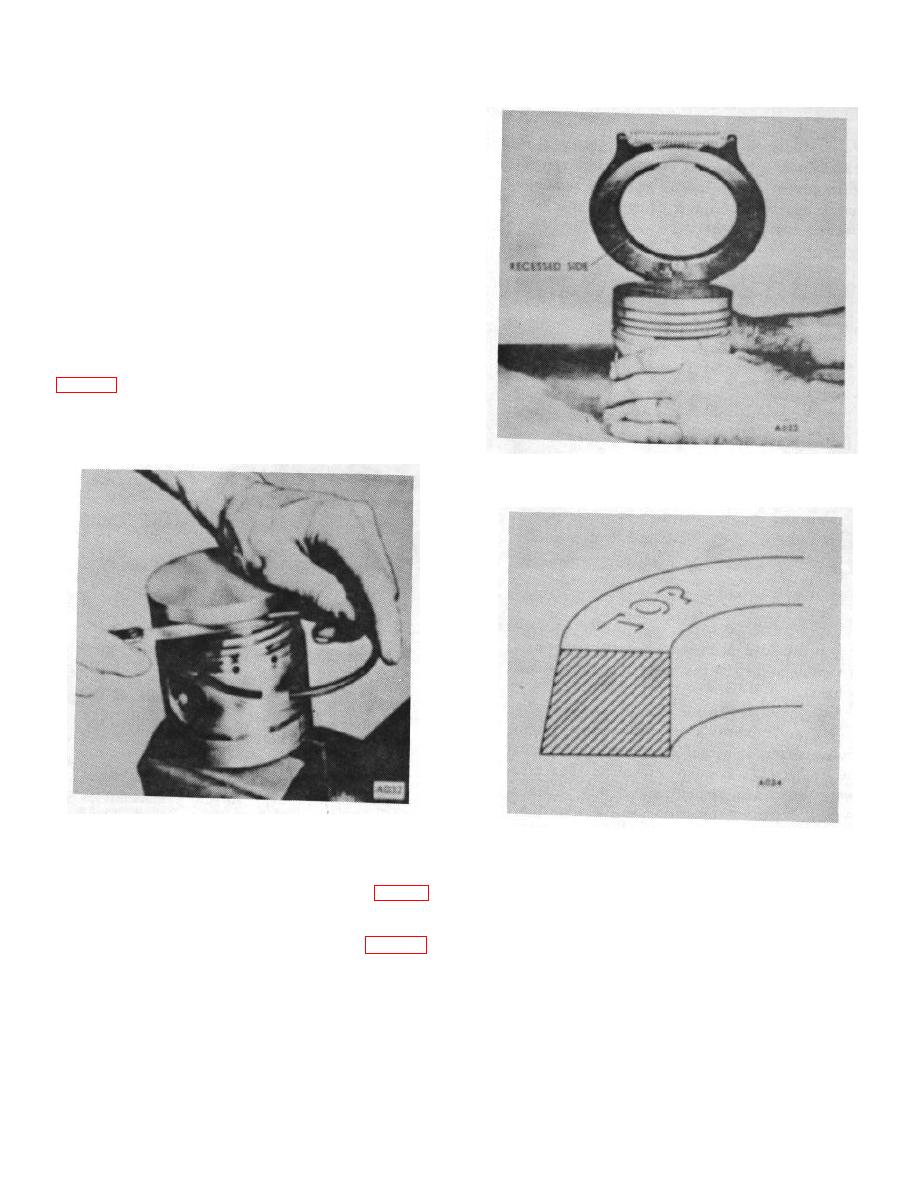

Figure 32.

Figure 31.

Figure 33.

3. Hold the ring tool with recess side up and place

4. Position ring in the tool so the expanding fingers

the ring in the groove with the bottom side up. (Fig. 32)

will fully engage both ends.

Start with the lowest ring first. Some piston rings are

taper-faced. These are clearly marked "TOP" on the

side to be up when assembled on piston. (Fig. 33)

5. Apply pressure on handles so ring is completely

expanded. Pass the expanded ring and tool, recessed

side down, over the piston to the proper groove.

B-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |