|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

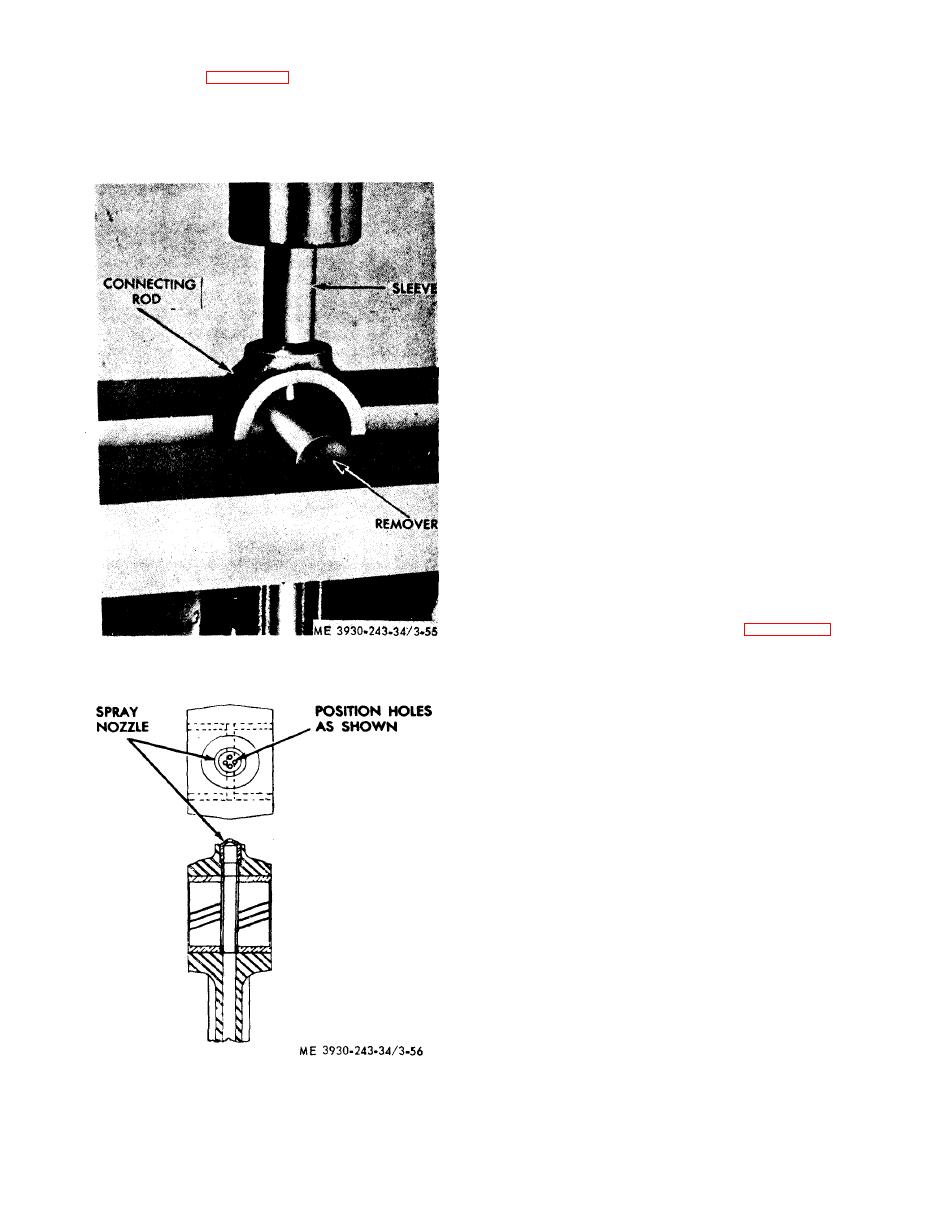

(5) Refer to figures 3-55 and 3-56 for removal

d. Cleaning and Inspection.

and installation of connecting rod spray nozzles.

(1) P i s t o n a n d R i n g s .

P r e s s new spray nozzle into connecting rod until it

(a) Clean all parts thoroughly with fuel oil

bottoms in counterbore.

and dry with compressed air. If fuel oil will not

remove carbon deposits, use F E D P - D - 6 8 0

cleaning solvent that will not attack the bushings or

t i n plating on the piston. The piston ring grooves

may be cleaned with a suitable tool, such as a

b r o k e n half of a compression ring sharpened to a

bevel edge.

(b) The cooling surfaces on the inside of the

p i s t o n should also be cleaned. Oil return holes in

t h e piston skirt must be thoroughly cleaned. Care

must be exercised so that holes are not enlarged

during the cleaning process. Excessively worn or

scored pistons, rings and cylinder liners indicate

abnormal maintenance or operating conditions

w h i c h should be corrected as quickly as possible.

Proper types of lubricating oil filters and air

cleaners and their maintenance will reduce to a

m i n i m u m the amount of abrasive dust and foreign

material introduced into the cylinder and will, in

turn, reduce the rate of wear.

(c) The protective coating on the skirt of the

piston is from 0.0007 to 0.0015 inch thick. The

p r e s e n c e of this coating of tin will, therefore, in-

dicate very little wear. A careful examination of the

piston should be made for scoring, burning, worn or

d a m a g e d ring grooves and cracks inside the piston

a c r o s s the struts. A badly scored piston should not

be reused, whereas a piston only slightly scored

may be cleaned up and reused. Refer to figure 3-57

for comparison of pistons.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |