|

|||

|

|

|||

|

Page Title:

Limiting Speed Mechanical Governor |

|

||

| ||||||||||

|

|

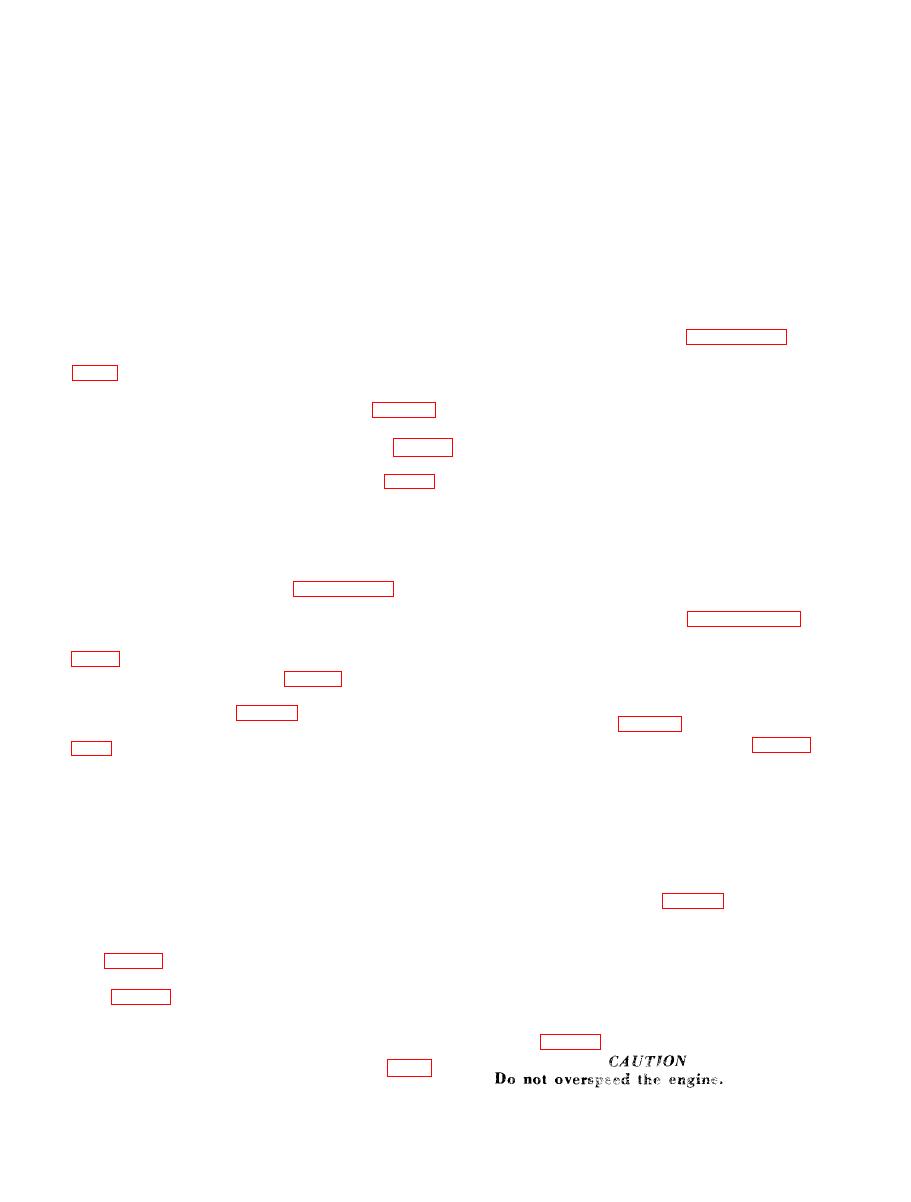

3-7. Limiting Speed Mechanical Governor

(3) Inspect the control lever link (37) needle

bearing (30) and control link lever pin (44) for

a. General. The limiting speed mechanical

wear. If a new control link lever pin is required

governor is mounted between the flywheel housing

remove the old pin and press the new pin in the

and the engine blower assembly. One end of the

governor housing; the new pin must project 1.055

governor weight shaft is splined to a drive plate

inch to 1.060 inch above the boss in the housing.

attached to the driven blower timing gear to

(4) Inspect the weight carrier, weights and

provide a means of driving the governor. The other

pins for excessive wear.

end of the shaft is supported by a bearing in the

(5) Inspect the governor springs, spring seat,

blower drive support. The governor controls the

spring cap, plunger, spring retainer, adjusting

engine idle speed and limits the maximum

screws for excessive wear.

operating speed of the engine. The governor

(6) Inspect the serrations on the governor

consists of four basic subassemblies: a cover and

weight shaft and drive plate on the blower timing

lever assembly; governor housing; spring housing;

gear for wear. Replace worn or damaged parts.

and a weight and shaft assembly.

e. Reassembly. Refer to figure 3-13 and

b. Removal. Since the governor is mounted

reassemble the governor assembly. Reassembly is

between the blower and the flywheel housing (fig.

the reverse order of disassembly.

3-12) the blower and blower drive support

CAUTION

assemblies must also be removed.

Do not use impact tools to install needle

(1) Remove the blower drive support (para 3-

bearings and do not break housing.

6).

(2) Remove the engine blower assembly (para

NOTE

3-5).

The low speed weights are identified by the long cam

(3) Remove the governor weight shaft (fig. 3-

arm, on the opposite side of the weight carrier. The

11) and carrier from the blower drive support,

high speed weights are identified by the short cam

arm.

using pry bars if necessary.

NOTE

(4) Remove the six attaching bolts and lock

The minimum clearance between the blower drive

washers and detach the governor housing from the

gear and governor weights must not be less than

blower rear end plate. Remove the gasket.

0.100 inch.

c. Disassembly. Refer to figure 3-13 and

f. Installation. Installation is the reverse

disassemble the limiting speed governor in

procedure of removal. Refer to paragraph 3-7 b.

numerical sequence as follows:

g. Adjust Governor Gap. With the engine at

(1) Disassemble governor cover (1 thru 22, fig.

normal operating temperature, set the governor gap

as follows:

(2) Remove two bolts (1, fig. 3-14) and washer

(1) With engine stopped, remove the two bolts

(2) and remove the spring housing (3) from

and with draw the governor high speed spring

governor housing (61, fig. 3-13).

retaining housing (3, fig. 3-14).

(3) Remove the spring retainer lock nut (5, fig.

(2) Back out the buffer screw (43, fig. 3-13)

extends 9/16 to 5/8 inch from the surface of the

(13).

governor housing.

(4) Remove the low speed spring cap (6),

CAUTION

spring ( 7 ) and spring seat ( 8 ) from spring plunger

Do not back the buffer screw out

(12).

beyond the limits given or the control

(5) Depress the high speed spring (11) by

link lever may disengage the dif-

hand and remove the idle speed adjusting screw

ferential lever.

lock nut (9). The spring retainer (13 ) and high

(3) Start the engine and loosen idle speed

speed spring (and shims) may be removed.

adjusting screw lock nut (9, fig. 3-14). Adjust the

Remove the idle speed adjust screw (10) from the

idle speed screw ( 10) to obtain the desired engine

spring plunger (12).

idle speed.

(6) Disassemble the governor housing (23 thru

(4) Stop the engine and remove the governor

51, fig. 3-13).

cover and the engine valve rocker covers. Discard

(7) Disassemble the governor weights (52 thru

the gaskets.

60) (para 3-6).

(5) Start and run engine, between 800 and

d. Inspection.

1,000 rpm, by manual operation of the differential

(1) Inspect all bearings for corrosion and

level (26, fig. 3-13).

pitting.

(2) Inspect the riser thrust bearing (52, fig. 3-

13).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |