|

|||

|

|

|||

|

Page Title:

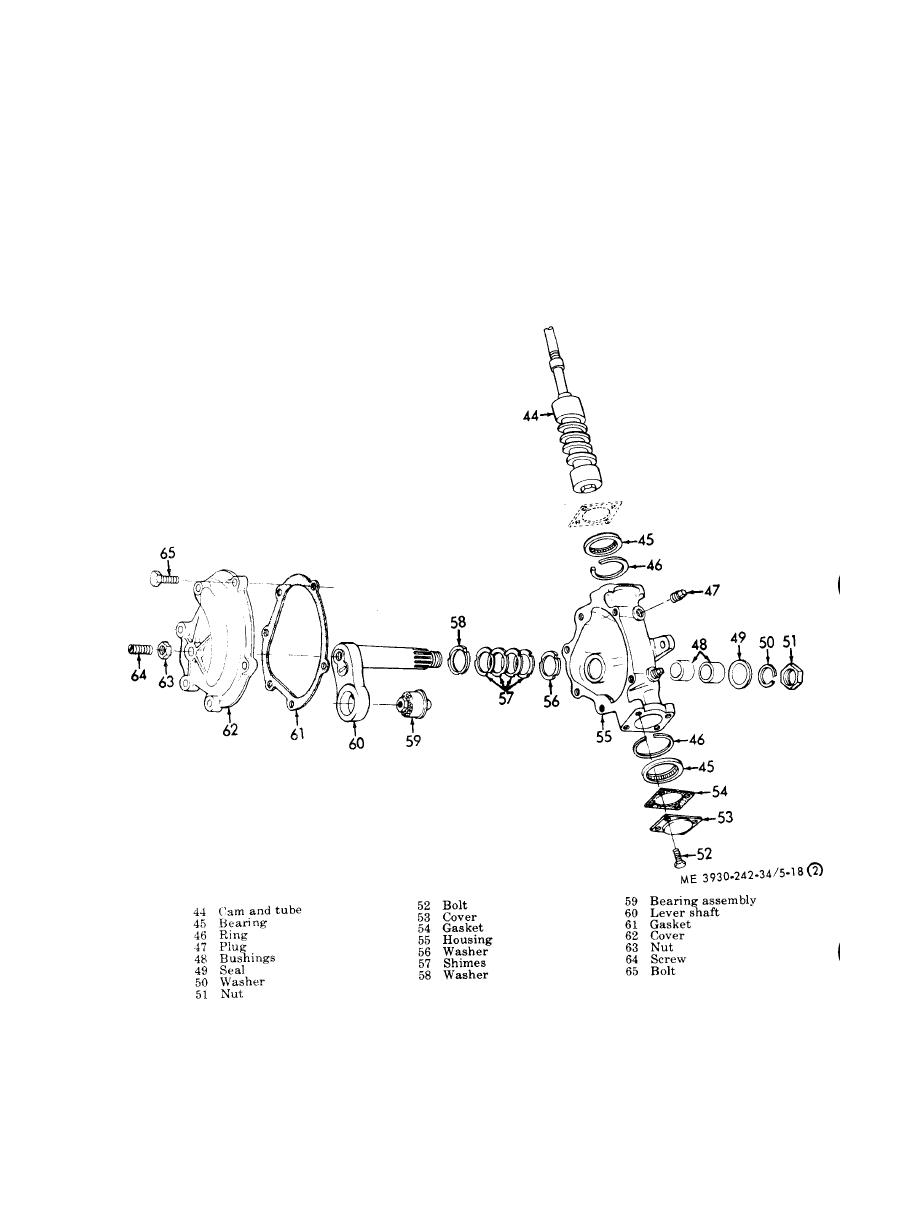

Figure 5-18. Steering gear assembly, disassembly and reassembly (sheet 2of 2) |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

o t h e r means will be necessary to correct this

(2) Reassemble screws in actuation housing

fault until the nut goes on freely.

(25) using 3/8-inch thick spacers under the head

( 5 ) Reassemble thrust washers, bearings,

of the screws. This is to hold the actuator (31)

t o n g u e d washers (with internal lug), pronged

and cam assembly (44) in the gear when making

w a s h e r (with 13 external prongs), and nut.

the adjustment.

(6) Tighten nut to 10 ft-lbs torque then back

(3) Straighten prong of lockwasher (34).

off nut 1020 degrees which can be done by mov-

Remove nut (35), tongued washer (33), upper

ing the nut approximately the width of one and

thrust washer (26) and bearing (27).

o n e - h a l f lugs. Bend the lug, nearest alinement,

( 4 ) Insure that the threads of the nut and

with a notch in the nut into a notch root on the

c a m shaft are free of interference by running

nut.

the nut onto the cam shaft by using only the

( 7 ) Reassemble upper cover and jacket tube

fingers to turn the nut. If the nut cannot be

a s s e m b l y and attaching parts.

tightened in this manner, use of a thread file or

Figure 5-18. Steering gear assembly, disassembly and reas-

sembly (sheet 2 of 2).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |