|

|||

|

|

|||

|

Page Title:

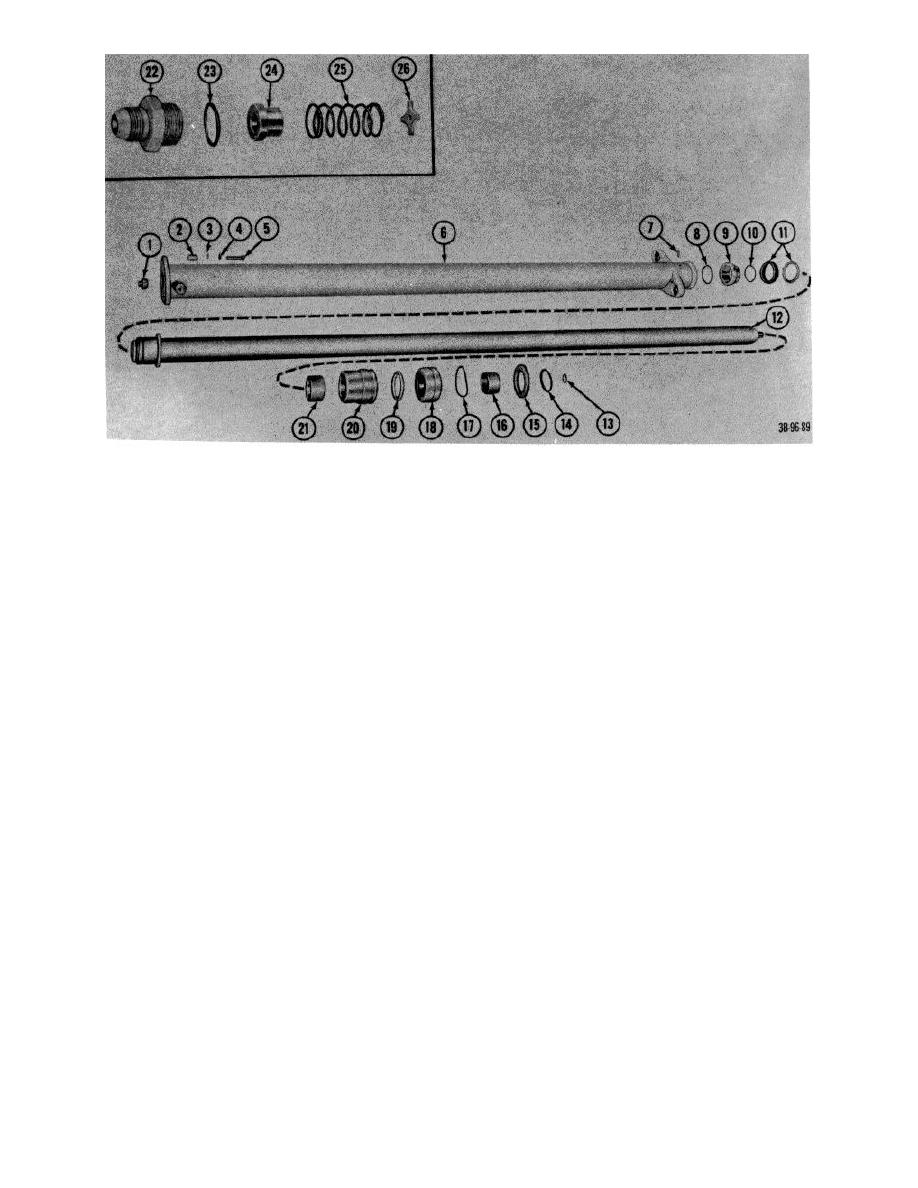

Figure 100. Tilt cylinder, exploded view. |

|

||

| ||||||||||

|

|

1

End, rod

16

Nut

2

Setscrew

17

Keeper

3

Washer, threaded

18

Lockwasher

4

Ring, wiper

19

Screw

5

Packing

20

Washer, special

6

Retainer

21

Pin

7

Packing, preformed

22

Shell

8

Bushing

23

Washer, special

9

Ring, backup

24

Packing, preformed

10

Packing, preformed

25

Elbow

11

Rod

26

Elbow

12

Piston half

27

Packing, preformed

13

Packing assembly

28

Nut, plain

14

Packing, preformed

29

Setscrew

15

Piston half

30

Fitting, lubrication

Figure 100. Tilt cylinder, exploded view.

(4) Slide plunger (12) from housing (6).

(1) Wash all parts in SD.

(5) Remove packing gland (18) and spacer

(2) Make certain that the adapter (22), spacer

(20) from plunger.

(24), spring (25), and special washer (26)

(6) Remove upper bushing (16), seal (19),

which make up the lowering control valve

and packing (17) from packing gland.

are thoroughly clean.

(7) Remove lower bushing (21) from spacer

(3) Inspect for scored cylinder walls.

(20).

(4) Check housing for cracks and breaks.

(8) Remove retaining ring (8) from bottom of

(5) Inspect piston and plunger for nicks and

plunger.

burs.

(9) Remove lower piston half (9), packing

(6) Replace all defective parts as authorized.

(10) and packing (11) from plunger.

(10) Remove fitting (22) from housing.

d. Assembly.

(11) Remove spacer (24), spring (25), and

(1) Lubricate all parts with hydraulic fluid.

special washer (20) from housing.

(2) Reverse procedures in b above.

(12) Remove packing (23) from fitting (22).

e. Installation

Reverse procedures in a above.

c. Cleaning, Inspection, and Repair.

AGO 7010A

121

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |