|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Measure gap with feeler gage (fig. 16).

pins are to be installed. (Piston pins are available in

0.005 inch oversize.) Hone bearing if roper pin fit is not

The gap should be 0.007 inch for all rings.

If the gap is less than specifications,

obtained. After assembling pin in piston, see that both

retaining rings are in place.

remove ring, and file ends until proper

gap is obtained.

(3) Check rings for proper side clearance

d. Fitting Piston Rings.

(par. 7 and fig. 17) and install them in

(1) Install piston ring in bore of cylinder.

proper groove on piston.

Invert piston and use it to push ring about

e. Fitting Pistons.

2 inches from bottom of bore.

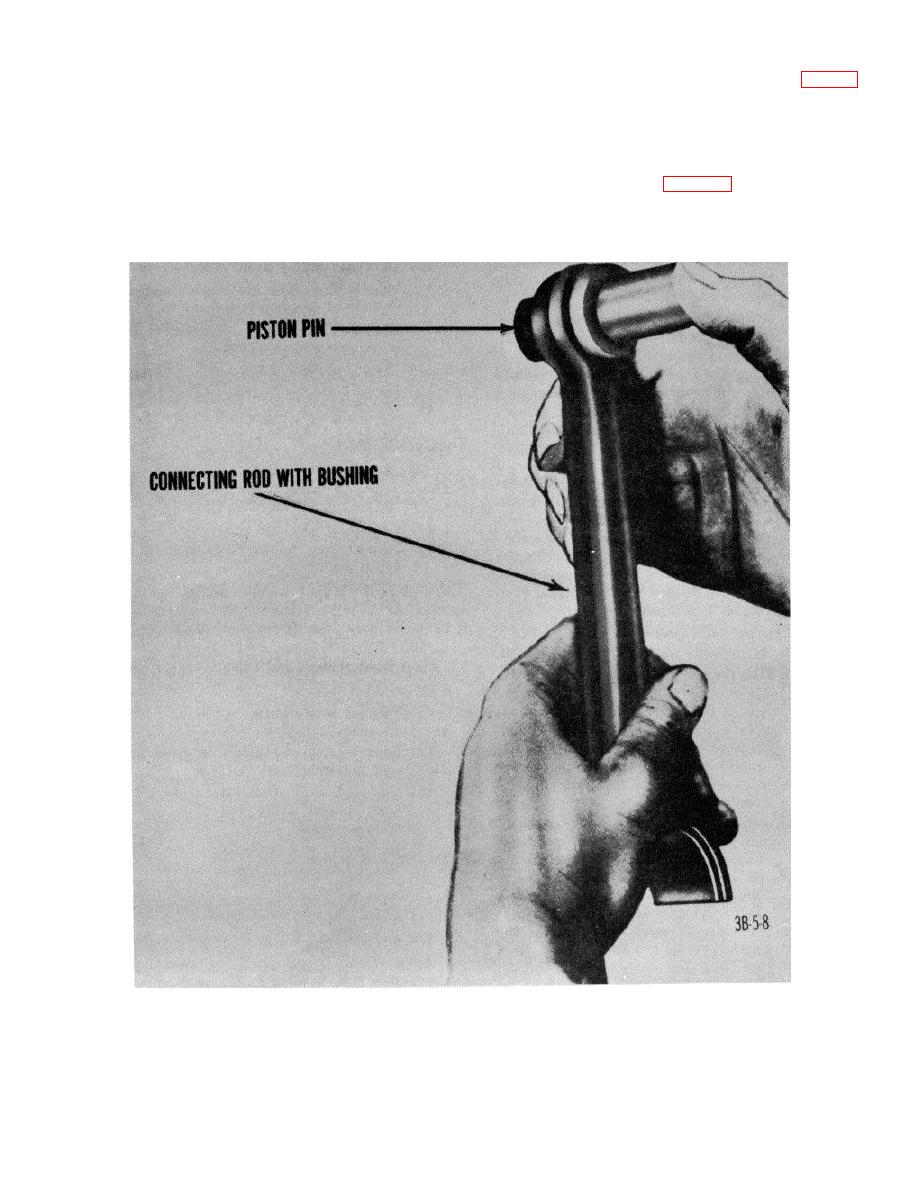

Figure 15. Fitting piston pin.

AGO 7010A

23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |