|

|||

|

|

|||

|

Page Title:

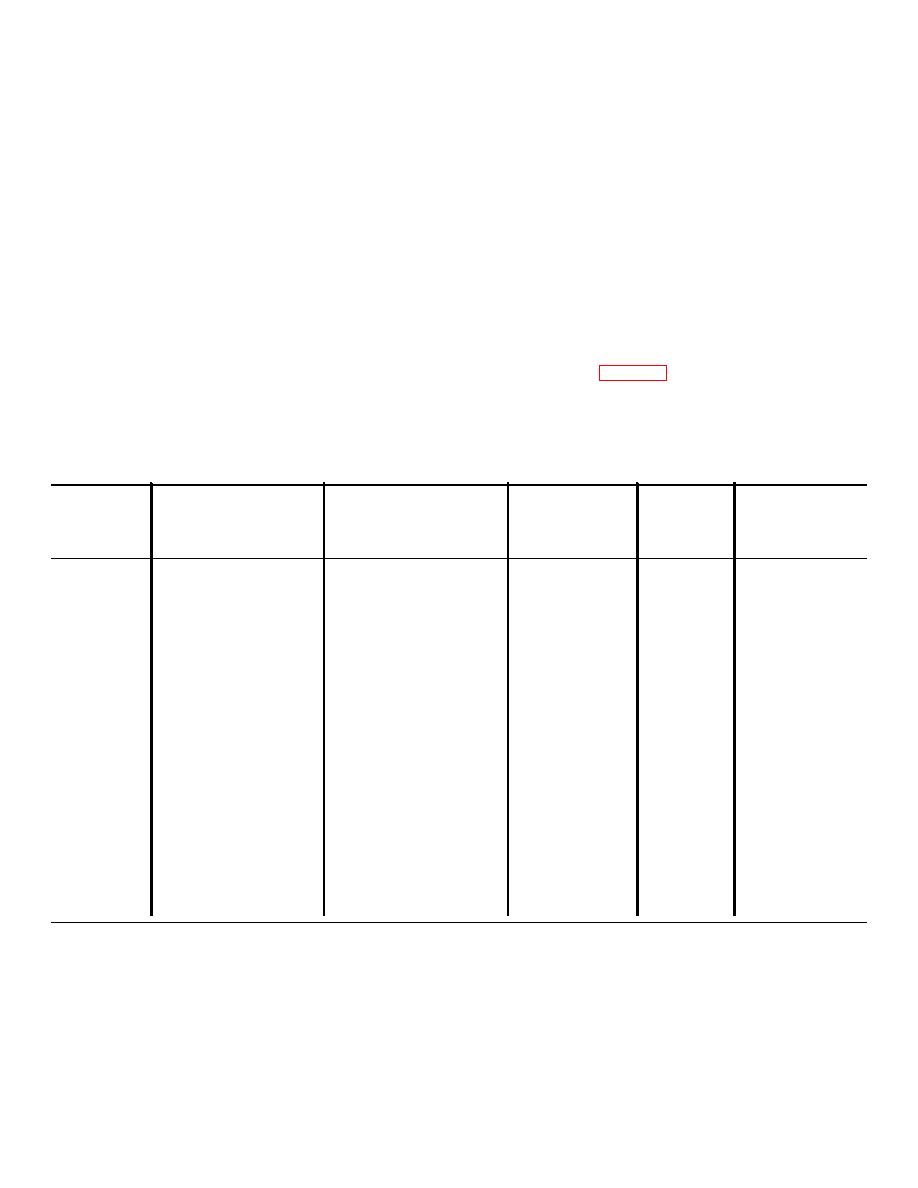

Table 4-1. Maintenance and Operating Supplies |

|

||

| ||||||||||

|

|

TM 10-3930-631-12

d. Remove any preservative compound that has

Mixing of the slightest amounts of

been sprayed on metal surfaces with cleaning

different electrolytes can damage the

compound, solvent (Fed. Spec. P-D-680) and dry

battery.

thoroughly.

e.

Check battery to determine type battery

installed. For lead acid type batteries, fill battery with

NOTE

electrolyte to 5/8 inch above the plates. For lead acid or

Preservative compound is not a

nickel/iron batteries, check specific gravity of electrolyte

lubricant.

Take special care to

as prescribed in TM 10-t 1690A/TO 19-75C BAE-13.

completely remove the compound from

Use battery charger, National stock number 6130-00-

all wearing surfaces.

500-0069, 36 volts to 60 volts, 160 amp. 230 volts ac,

WARNING

metallic rectifier type, alternating operating power, when

If battery is received with a metal cover,

charging lead acid or nickel/iron batteries.

remove and discard metal cover and

f. Lubricate the truck in accordance with the

install battery.

current lubrication order.

WARNING

g. Fill hydraulic reservoir with proper grade of oil.

When servicing battery, do not smoke or

Refer to current lubrication order.

use flame in the vicinity.

Batteries

h. Refer to Table 4-1 for a list of maintenance and

generate hydrogen, a highly explosive

operating supplies required for initial operation of the fork

gas. Do not use the same hydrometer to

lift truck.

check specific gravity of nickel/iron,

nickel/cadmium or lead acid batteries.

Table 4-1. Maintenance and Operating Supplies

(1)

(2)

(3)

(4)

(5)

(6)

Component

National

Description

Quantity

Quantity

Notes

Application

Stock No.

Required for

Required for

Initial

8 Hrs

Hydraulic Brake

OIL, , HYDRAULIC: 1 gal can

(1) See current LO for

System

as follows:

grade application and

HB--nonpetroleum base,

2 pt.

(1)

replenishmentin-

automotive.

tervals.

9150-00-262-9375

HBA--nonpetroleum base,

/2 pt.

(1)

(2) Includes quantity

to

automotive, arctic-type

.fill hydraulic system

as follows:

Differential

OIL, LUBRICATING, GEAR:

1 qt.--filter

55 gal drum as lollows:

21'2 qt.-lines

3 3/4 gal.--reservoir

GO 90

6 pt.

(1)

(3) See C9100-IL for

9150-00-240-2244(3)

GO 75

6 pt.

(1)

additional data and

9150-00-257-5422(3)

GOS

6 pt.

(1)

requisitioning pro-

cedure.

Hydraulic System

OIL, LUBRICATING: 55 gal

drum as follows:

OE 10

21 qt.

(1)

(2)

OES

21 qt.

(2)

Lubricating

GREASE, AUTOMOTIVE

Fittings

AND ARTILLERY: 35 lb.

can as follows:

)GAA

As

(1)

required

b. Fire Extinguisher. Remove separately packed

4-2. Installation of Separately Packed Com-

fire extinguisher and install in bracket on instrument

ponents

panel. Be certain bracket clamp locks properly to secure

Components.

The only components not

a.

fire extinguisher in position.

already installed are the forks, battery and the fire

extinguisher.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |