|

|||

|

|

|||

|

Page Title:

FORK SIDESHIFT CYLINDERS MAINTENANCE |

|

||

| ||||||||||

|

|

TM 10-3930-660-24-2

FORK SIDESHIFT CYLINDERS MAINTENANCE

THIS WORK PACKAGE COVERS

Disassembly, Cleaning, Inspection, Assembly

INITIAL SETUP

Materials/Parts - Continued

Tools and Special Tools

O-ring (10 and 16)

Tool kit, general mechanic's (Item 39, WP 0324 00)

Seal (12, 13, 15 and 19)

Shop equipment, automotive maintenance (Item 21,

Wear ring (18)

Spanner wrench, fork sideshift cylinder, outer gland

References

(Item 27, WP 0324 00)

Materials/Parts

TM 10-3930-660-10

Oil, lubricating (Item 33, WP 0323 00)

Rag, wiping (Item 40, WP 0323 00)

Equipment Condition

Fork sideshift cylinder removed (WP 0200 00)

Back-up ring (11 and 17)

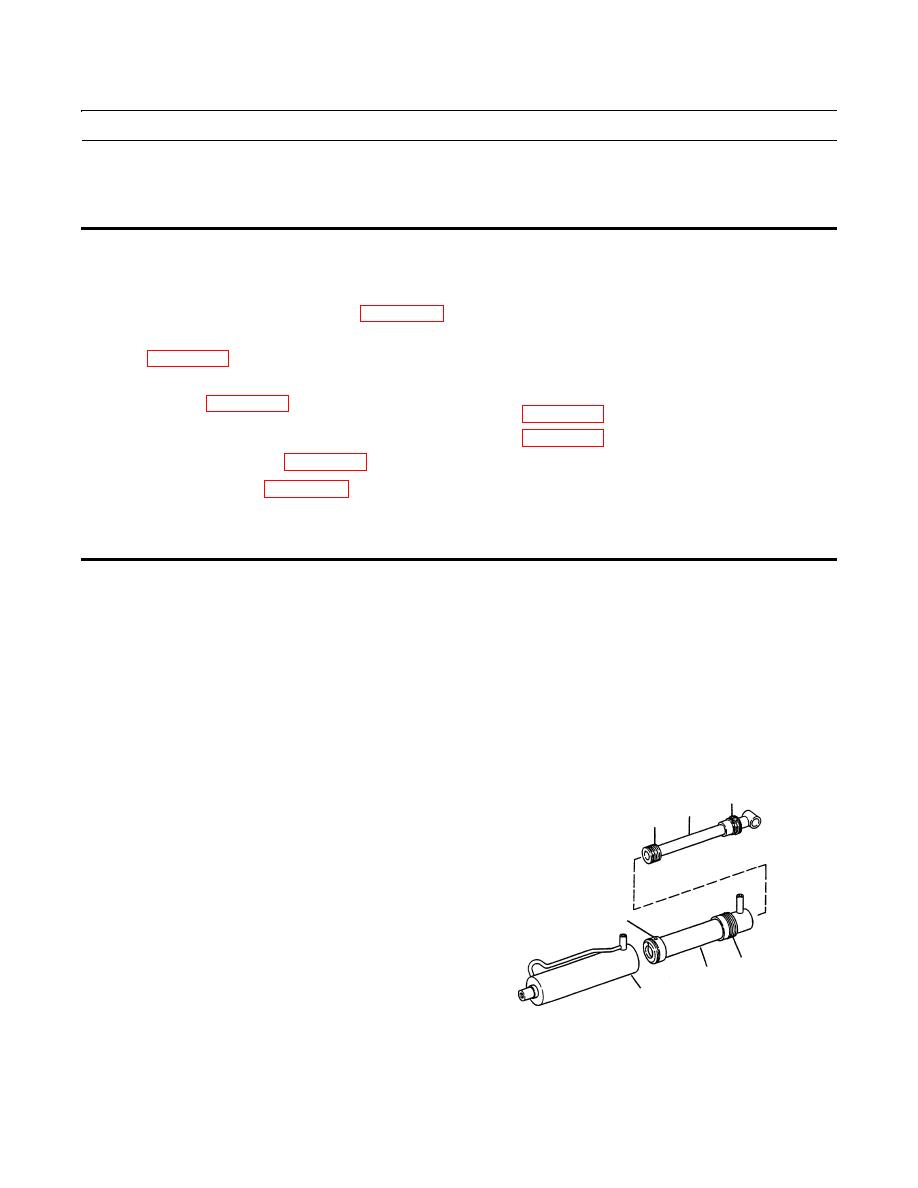

DISASSEMBLY

CAUTION

Do not scratch or damage the wear surface of rod, piston or inner gland. Follow this precaution to prevent

failure of the cylinder.

NOTE

Use a vise with soft jaws to secure cylinder in a horizontal position for disassembly.

1.

Pull rod (1) out approximately 5 in. (12.7 cm) for

2

1

removal of inner gland (2).

3

2.

Place a container under inner gland (2) to catch oil

contained in cylinder.

CAUTION

Use care when removing rod and piston

7

assembly to prevent seal damage. Keep

rod in line with barrel to prevent binding.

4

6

5

409-1456

3.

Use a spanner wrench to unscrew inner gland (2) from rod (1). Remove rod (1), inner gland (2) and inner piston (3) as an

assembly. Clamp assembly in a holding device.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |