|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

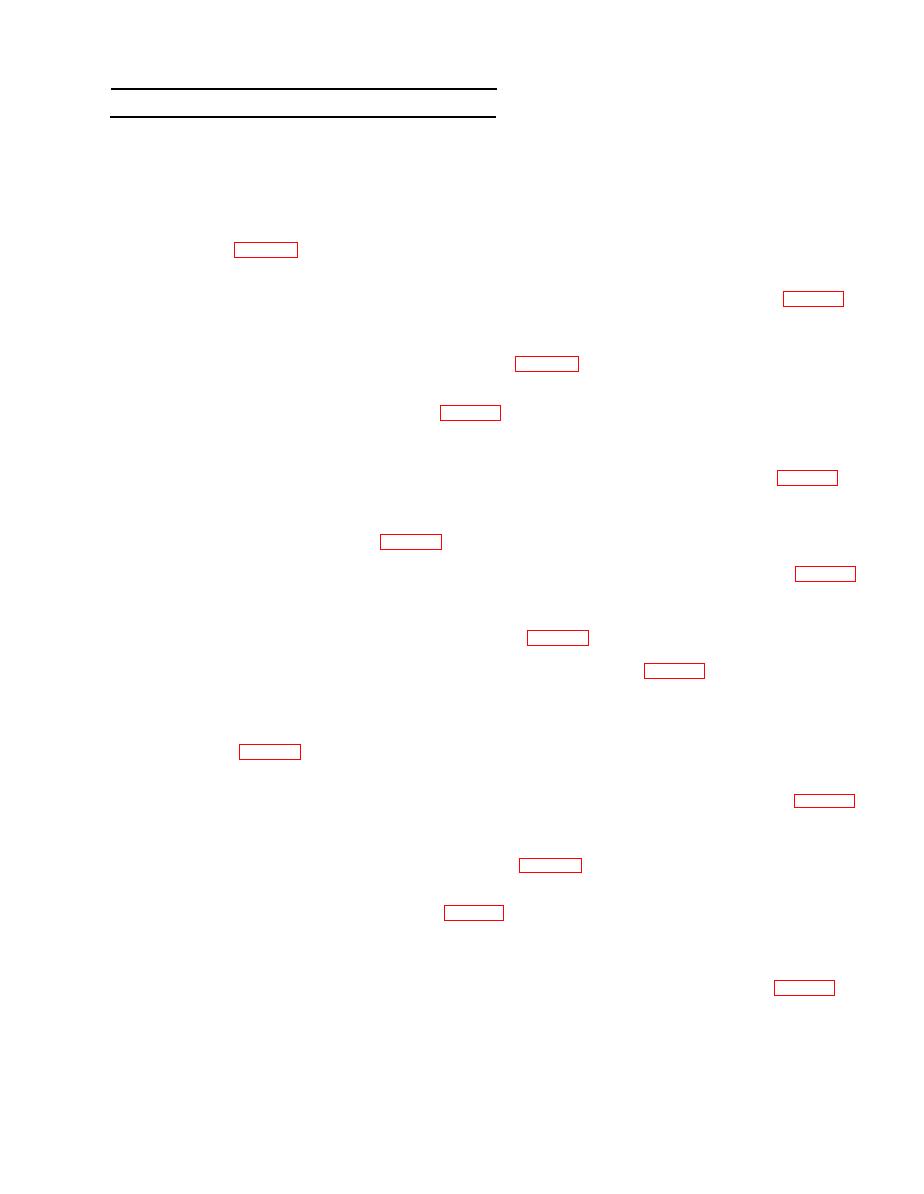

3-3. ENGINE TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. ENGINE STARTS BUT WILL NOT RUN (cont)

Step 2. Check for correct valve timing in reference to crankshaft timing marks with dial indicator

a. If correct valve timing in reference to crankshaft timing marks is not obtained, check for sheared

key in cam drive gear or broken cam shaft (notify general support maintenance) (para 4-2g).

b. If correct valve timing in reference to crankshaft timing marks is obtained, proceed to step 3.

Step 3. Perform compression test of each cylinder (para 3-3, MALFUNCTION 7).

If compression test is satisfactory, test fuel injector nozzles before reinstalling on engine (notify

general support maintenance) (para 4-3b). If fuel injector test is satisfactory, proceed to step 4.

Step 4. Start engine and listen for excessive valve tappet noise.

If excessive valve tappet noise is heard, stop engine and check for bent push rods (para 3-5j).

4. ENGINE MISFIRES

Step 1. Remove fuel injectors (para 3-6b) and check for damaged fuel injector nozzle seal.

a. If fuel injector nozzle seal is damaged, replace (notify general support maintenance) (para 4-3a).

b. If fuel injection seals are okay, proceed to step 2.

Step 2. Check for proper fuel injection pump timing (para 3-5a(3)).

a. If fuel injection pump timing is not correct, adjust timing (para 3-5a(3)).

b. If fuel injection pump timing is okay, proceed to step 3.

Step 3. Check for correct valve timing in reference to crankshaft timing marks with dial indicator

a. If correct valve timing in reference to crankshaft timing marks is not obtained, check for sheared

key in cam drive gear or a broken cam shaft (notify general support maintenance) (para 4-2g).

b. If correct valve timing in reference to crankshaft timing marks is obtained, proceed to step 4.

Step 4. Perform compression test of each cylinder (para 3-3, MALFUNCTION 7).

If compression test is satisfactory, test fuel injector nozzle before reinstalling on engine (notify

general support maintenance) (para 4-3a). If fuel injector test is satisfactory, proceed to step 5.

Step 5. Start engine and listen for excessive valve tappet noise.

If excessive valve tappet noise is heard, stop engine and check for bent push rods (para 3-5j).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |