|

|||

|

|

|||

|

Page Title:

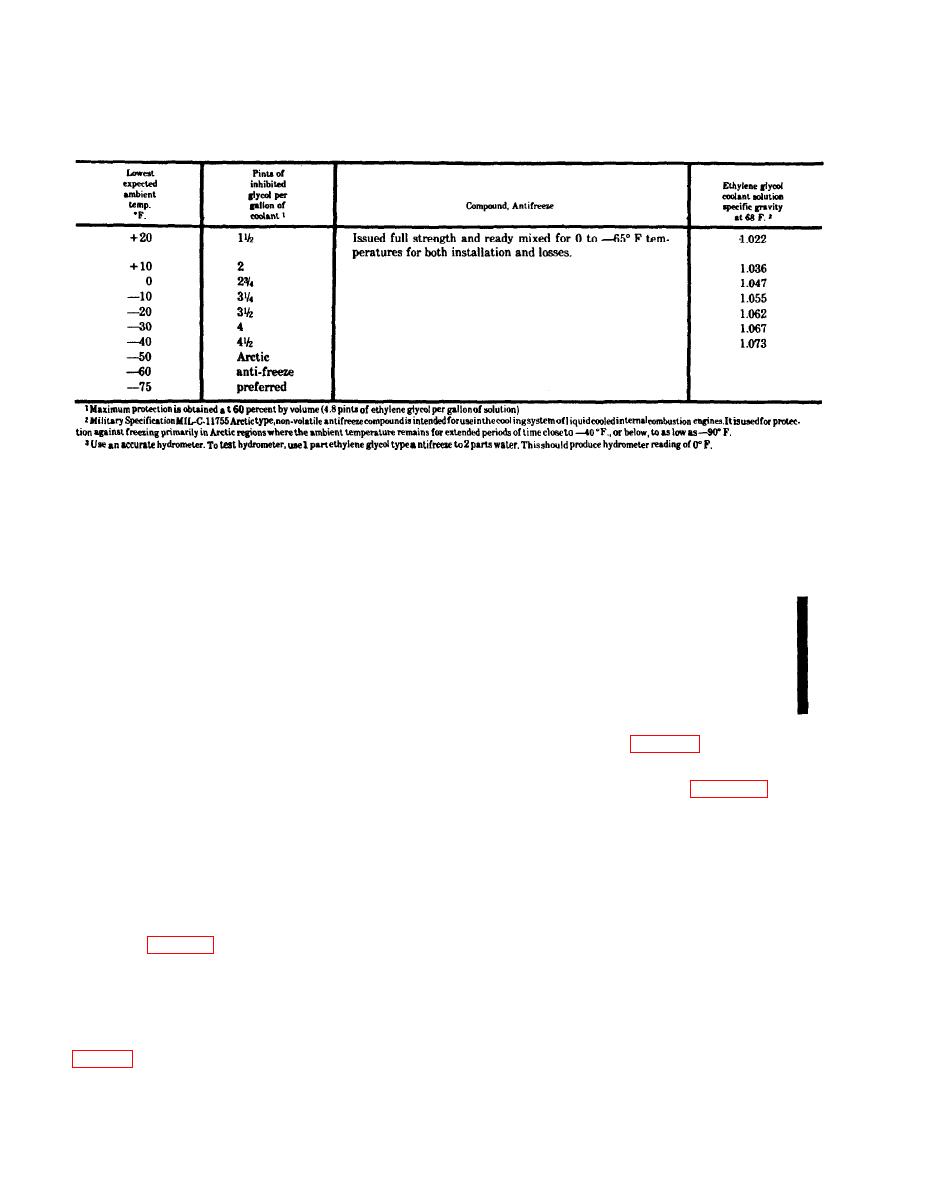

Table 2-1. Freezing Points, Composition and Specific Gravities of Military Antifreeze Material |

|

||

| ||||||||||

|

|

TM 10-3930-634-12

the engine one priming charge before engaging the

i. Allow engine to reach normal operating tem-

starter. Then proceed as in g above.

perature before applying load.

Table 2-1. Freezing Points, Composition and Specific Gravities of Military Antifreeze Material

a. General. The ether primer is a pressurized system

used to inject a highly volatile fluid into the engine air

a. Clean all grease fittings.

intake system. This is to facilitate starting when am-

b. Lubricate in accordance with current lubrica-

bient temperatures are below 40F. The replaceable

tion order.

pressurized cylinder contains sufficient fluid for 75 to

150 starts.

c. Change engine oil and oil filter frequently.

b. Operating the Ether Priming System.

WARNING

(1) Pull up on the ether primer button for about 2

If NBC exposure is suspected, all air fil-

seconds. Wait 3 seconds, then crank engine. With

ter media should be handled by personnel

engine turning, push the ether primer button down.

wearing protective equipment. Consult

(2) Perform normal starting procedures (para.

your unit NBC Officer or NBC NCO for

2-3).

appropriate handling or disposal instruc-

(3) If engine fails to start, refer to troubleshooting

tions.

chart.

the engine proper air intake.

WARNING

Be extremely careful when removing the

radiator filler cap of a hot engine. Release of

pressure may cause violent boiling and

serious injury to personnel.

a. Keep all lubricating points wiped clean and

a. Insure that radiator filler cap seals properly. The

well lubricated

boiling point of the coolant is raised as the system pres-

sure is increased.

b. Keep all wiring and ignition terminals free of

b. Check coolant level frequently. Add coolant as

corrosion.

necessary. Use standard ethylene glycol mixture as

c. Keep forklift truck as clean as possible.

specified in table 2-1.

c. Remove all obstructions and foreign material col-

d. After operation is complete, wash truck with

lected on radiator fins and air passages.

fresh water. Lubricate in accordance with lubr-

d. Do not overfill fuel tank. Make sure fuel filters are

ication order. Check all gear cases for water con-

clean.

tamination. If contamination is found (evidenced

by milky color of lubricant), drain, flush and re-

e. Make sure air cleaner is cleaned and serviced

fill.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |